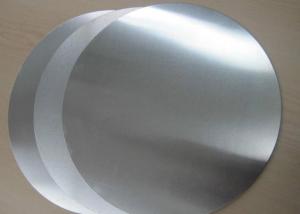

High Quality Aluminum 3003/8011 Color Coated Mill Price Aluminum Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Aluminium Circle for Cooking Utensils

1. Alloy: 3003, 8011

2. Temper: O,H12,H14,H16,H18,H19,H22,H24,H26

3. Hardness: 26 ~ 29

4. Elongation Percentage: 36% ~ 45%

5. Surface Treatment: Coated or Non-Coated

6. Thickness: 0.50mm ~ 6mm

7. Diameter: 100mm - 1520mm

8. Type: Discs, Circle

Product Applications:

Deep drawing quality,Less Scrap.

Suitable for making cookware and following products:

+Stock pots +Fry pans +Tea kettles

+Pressure cookers +Pizza pans + Rice cookers

+Restaurant cookware +Coffee urns + Electric skillets

+Bakeware, Bread Makers + Stainless cookware bottom plates.

Packing And Loading:

Standard Export Package And Customized Packing Ways Are Welcomed

- Q: This question asks for various applications of recycled aluminum other than its traditional uses.

- <p>Recycled aluminum has a wide range of alternative uses. It can be used in the manufacturing of new aluminum products, reducing the need for raw materials. It's also used in construction for window frames, doors, and roofing. In the automotive industry, recycled aluminum is used for car parts, helping to reduce vehicle weight and improve fuel efficiency. Additionally, it's utilized in the aerospace industry for lightweight aircraft components. Recycled aluminum is also found in everyday items like cans, foil, and packaging materials. Furthermore, it's used in electrical components due to its excellent conductivity, and in the production of bicycles and sports equipment for its strength and lightweight properties.</p>

- Q: Is it safe or permissible to use aluminum in food packaging materials?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against air, moisture, and light. It is used in various forms such as aluminum foil, cans, and flexible packaging materials. However, it's important to ensure that the aluminum packaging is food-grade and complies with safety regulations to prevent any potential health risks associated with aluminum exposure.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: Describe the process of electrolysis used in aluminum production.

- <p>The process of electrolysis for aluminum production involves the Hall-H茅roult process, which is the primary method for extracting aluminum from its ore, bauxite. First, bauxite is refined to produce aluminum oxide (alumina). This alumina is then dissolved in a molten cryolite bath, which lowers the melting point and increases the electrical conductivity. Large amounts of electricity are passed through the bath, causing the alumina to decompose into aluminum metal and oxygen gas. The aluminum collects at the bottom of the cell and is periodically tapped off, while the oxygen is released into the atmosphere. This energy-intensive process is crucial for the aluminum industry, as it allows for the production of large quantities of aluminum, a key material in various industries.</p>

- Q: Is it possible to construct vehicles using aluminum?

- <p>Yes, aluminum can be used to make cars. It is known for its lightweight, high strength, and corrosion resistance, which are desirable properties in automotive manufacturing. Aluminum alloys are commonly used in car bodies, engines, and other components to reduce weight, improve fuel efficiency, and enhance performance. Additionally, its recyclability makes it an environmentally friendly choice for vehicle production.</p>

- Q: This question asks for the current cost of aluminum.

- <p>The cost of aluminum fluctuates based on market conditions and can vary by region. As of my last update, the price of aluminum was around $2,500 per metric ton, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with a commodity exchange or a reliable financial news source. Prices can be influenced by supply and demand, economic indicators, and geopolitical factors.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: Is it possible to utilize aluminum in the construction of airplanes to enhance fuel efficiency?

- <p>Yes, using aluminum can make airplanes more fuel efficient. Aluminum is lightweight, which reduces the overall weight of the aircraft, leading to lower fuel consumption. Additionally, aluminum has good strength-to-weight ratio and is resistant to corrosion, making it a popular material in aircraft construction. However, it's important to note that the use of aluminum must be balanced with other materials to ensure structural integrity and safety.</p>

- Q: Compared with other aluminum veneers, what are the advantages?

- 1, exquisite appearance, grain pattern rich, realistic effect, clear texture.2, fire resistance: corrosion resistance, moisture resistance, hardness and strength are compared to wood floating method.3, rust prevention, anti damage, UV protection.4, long service life, can maintain 10-15 years without color, no deformation.5, strong plasticity, can be processed into a variety of complex shapes, the back of which can be filled with insulation, sound insulation, sound-absorbing and other materials, so that its function more rich.6, environmental protection, ecological environment protection, reduce waste of materials and resources.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum in the construction of solar panels.

- <p>Aluminum offers several advantages in solar panel construction, such as its lightweight nature, which reduces the overall weight of the panels and makes them easier to install. It is also highly conductive, enhancing the efficiency of electricity generation. Additionally, aluminum is corrosion-resistant and durable, which means it can withstand harsh weather conditions and last longer. However, there are disadvantages, such as its relatively low strength compared to other metals, which could lead to damage under high stress. Aluminum also has a higher reflectivity, which can reduce the amount of sunlight absorbed by the solar cells. Lastly, while aluminum is abundant, its extraction and processing can have environmental impacts, contributing to carbon emissions and resource depletion.</p>

Send your message to us

High Quality Aluminum 3003/8011 Color Coated Mill Price Aluminum Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches