Aluminum Thick Plate for shoes mold 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Thick Plate for Shoe Molds Description:

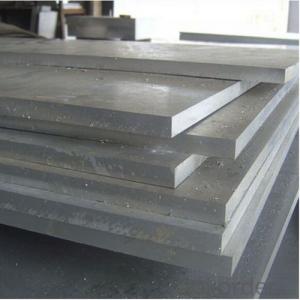

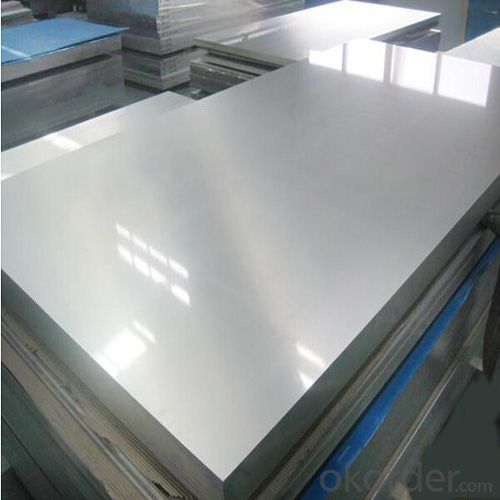

Our company can supply aluminium thick plates 6061. The thickness is 2mm-250mm, the common surface is polished with clear PVC film. The temper is T6, T651, F, H ect.

2.Main Features of Aluminum Thick Plate for Shoe Molds :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

3. Aluminum Thick Plate for Shoe Molds Images:

4. Aluminum Thick Plate for Shoe Molds Specification:

| Specification | Name: 6000 series Aluminum Plate | |||||||||||

| Alloy: 6061, 6082 etc. | ||||||||||||

| Temper: O, H112, T6, T651 etc. | ||||||||||||

| Thickness: 6-200mm | ||||||||||||

| Width: Up to 1500mm | ||||||||||||

| Surface treatment: mill finished, Print marks | ||||||||||||

| Feature | Machinability: In the harder T 4 and T6 tempers it is good. It is notably less easy to machine in the annealed temper. | |||||||||||

| Forming: Easily cold worked and formed in the annealed condition. Stamping, bending, spinning, deep drawing are all readily accomplished using standard methods. | ||||||||||||

| Welding: It has very good welding characteristics and may be welded by all of the common welding techniques. | ||||||||||||

| Heat Treatment: Solution heat treat at 990 F for adequate time to allow for thorough heating and then water quench. Precipitation hardening is done at 320 F for 18 hours and air cool, followed by 350 F for 8 hours and air cooling. | ||||||||||||

| Forging: It is capable of being hot forged at temperatures in the range of 900 F to 750 F. | ||||||||||||

| Hot Working: Hot working may be done in the temperature range of 700 F to 500 F. | ||||||||||||

| Cold Working: Cold working in the O temper condition is readily performed. The alloy is notably less easy to cold form in the T 4 and T 6 tempers. | ||||||||||||

| Annealing: Annealing should be done at 775 F for 2 to 3 hours followed by controlled cooling at 50 f per hour down to 500 F, then air cool. | ||||||||||||

| Aging: The aging precipitation heat treatment is done at 350 F for 8 hours followed by air cooling. This produces the T6 temper. | ||||||||||||

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminum would only make sense in low current applications where cost and weight are important.

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets exhibit a relatively high coefficient of thermal expansion, causing them to expand significantly under heat and contract when cooled. This behavior stems from aluminum's nature as a metal with a relatively low melting point and excellent heat conductivity. Heating aluminum sheets increases the energy of its metal atoms, causing them to vibrate and move more rapidly, resulting in expansion. Conversely, cooling the sheets reduces their energy, causing the metal atoms to slow down and move closer together, leading to contraction. Therefore, it is crucial to consider the thermal expansion properties of aluminum sheets when using them in applications that involve temperature fluctuations, as this can impact the material's overall dimensions and performance.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: 8mm which type of aluminum plate is suitable for bending?

- Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.

- Q: Which kind of material does aluminum sheet(aluminum oxide) belong to?

- it's metal and belongs to hardware

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- A for a swinging pendulum period T =2pi*√(L/g), where L is length of the pendulum, g=9.8m/s^2; metals shrink when cooled, so period will decrease, number of ticks per hour will increase, the clock will hurry up; B? period at t1°=20C° is T1=2pi*√(L1/g); ? period at t2°=-5C° is T2=2pi*√(L2/g); ? the law of linear extension says L2/L1= 1+s*Δt°, where s=23.1·10-6 (1/К°) is specific linear extension of aluminum, Δt°=t2°-t1°; ? thus T2/T1 =√(L2/L1) = √(1+s*Δt°) =f1/f2, where frequency f1= 1 Hz at 20C° or 3600 ticks per hour, hence frequency at -5C° is f2= f1/√(1+s*Δt°); therefore instead of 3600 ticks per hour the clock will do 3600/√(1+s*Δt°) ticks per hour; thus it will gain 3600*(1/√(1+s*Δt°) –1) = = 3600*(1/√(1 -23.1·10-6 *25°) –1) = 1.04 s/hour;

- Q: Not just cans. How is aluminum recycled and what is the process. Not the scientific formula! How its done entering the plant.

- Aluminum okorder

- Q: Can aluminum sheets be used for roofing applications?

- Aluminum sheets are suitable for roofing due to their lightweight and durable nature, along with their excellent resistance to corrosion. They are particularly well-suited for areas with high humidity or coastal regions that experience saltwater exposure. Known for their longevity and low maintenance requirements, aluminum roofing sheets are also fire-resistant and can withstand extreme weather conditions. This makes them a popular choice for residential and commercial roofing projects. Furthermore, aluminum sheets are easy to install and can be shaped and formed to fit various roof designs. In addition to their practical benefits, aluminum is an environmentally friendly option for roofing applications as it can be recycled repeatedly without any loss in quality.

Send your message to us

Aluminum Thick Plate for shoes mold 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords