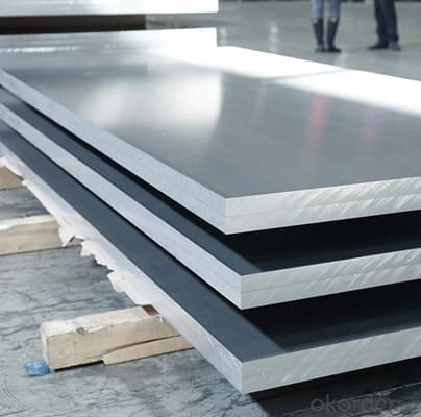

6061 aluminium polished thick plates 8-150mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of 6061 ALUMINIUM POLISHED PLATES

All the alloy we can supply:

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Normally, when I install a 30-amp dryer receptacle, the wire is #10 copper and I double over the end with lineman's pliers prior to landing it in the lug just to be extra tight. Today I replaced a dryer outlet wired with #8 aluminum SE. The quandaray I have is that the lugs seem made for #6 and the #8 just sort of flattens and divides under the screw. Is this safe? The doubling over move makes the wire way too thick for the lugs to close. I've been doing electric for many years and have never run into this. Should I go back and re-run the circuit (only about 30 feet) in #10 copper? What is the actual draw of a typical electric dryer on high heat, anyway? Thanks.

- Make sure all work is done to code, we had a house with aluminum wiring, it gets hot when a larger load is applied. When selling, the couple who bought it had an inspector come and he said we had to do all this work or they could not get a mortgage. Whatever you do, make sure it is fully up to code, or you will have alot of trouble selling your home one day.

- Q: Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is lightweight, resistant to corrosion, and can be easily shaped into cans. It also provides a protective barrier against light and air, ensuring the quality and freshness of the beverages inside.

- Q: What kind of paint would you like to paint on the aluminum plate?

- Try to brush the high quality magnetization paint, the aluminum plate brush can be brushed, will not move, also won't fall lightly.

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on various factors such as the size, thickness, and grade of the sheet, as well as the supplier and market conditions. Generally, aluminum sheets can range in price from around $0.50 to $5 per square foot. Thinner sheets or lower-grade aluminum may be on the lower end of the price range, while thicker sheets or higher-grade aluminum can be on the higher end. It is always recommended to compare prices from different suppliers to get the best deal.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: What are the different types of coatings available for aluminum sheets?

- Aluminum sheets come in various coatings, each with its own unique properties and advantages. 1. Anodized Coating: To create an anodized coating, the aluminum sheet is immersed in an electrolyte bath and an electric current is passed through it. This process forms a durable and corrosion-resistant oxide layer on the sheet's surface. Anodized coatings can be found in different colors and provide excellent resistance to abrasion. 2. Powder Coating: In powder coating, a dry powder is applied to the aluminum sheet and then heated to cure it. This method results in a durable, uniform, and visually appealing finish. Powder coatings are available in a wide range of colors and textures and exhibit excellent resistance to chipping, scratching, and UV fading. 3. Paint Coating: Liquid paint can be used to coat aluminum sheets, offering versatility in terms of color and finish options. Paint coatings provide good resistance against weathering, impacts, and chemicals, although they may not be as long-lasting as anodized or powder coatings. 4. Cladding: Cladding involves bonding a layer of a different metal, such as stainless steel or copper, to the surface of the aluminum sheet. This process enhances protection, improves aesthetic appeal, and enhances the sheet's mechanical properties. 5. Laminating: Laminating consists of bonding a protective layer, such as a film or sheet, to the surface of the aluminum sheet. This coating method offers protection against abrasion, UV rays, and chemicals, while also providing decorative finishes. 6. Organic Coating: Organic coatings, such as polyurethane or acrylic coatings, are applied to aluminum sheets to protect against corrosion, weathering, and chemical exposure. These coatings offer flexibility, good adhesion, and a wide array of color choices. The choice of coating for aluminum sheets depends on specific requirements, including durability, corrosion resistance, aesthetic appeal, and cost-effectiveness.

- Q: Can aluminum sheets be stamped or pressed?

- Yes, aluminum sheets can be stamped or pressed. Aluminum is a highly malleable metal that can be easily shaped and formed through various manufacturing processes. Stamping and pressing are commonly used techniques to create intricate designs, shapes, and patterns on aluminum sheets. These processes involve applying pressure to the sheet using specialized equipment, such as stamping presses or hydraulic presses, to deform the material and create the desired shape. Stamping and pressing are widely used in industries such as automotive, aerospace, construction, and manufacturing, where aluminum sheets are often used for their lightweight, durable, and corrosion-resistant properties.

- Q: What are the different types of aluminum sheets?

- There exists a variety of aluminum sheets, each possessing distinct characteristics and applications. Here are some commonly encountered types: 1. The plain aluminum sheet, with its smooth surface and uniform thickness, serves as the fundamental option. It holds widespread usage across various industries for general purposes. 2. The embossed aluminum sheet, achieved by rolling the metal through a patterned roller, presents a textured or patterned surface. It finds common application in fields like interior design or automotive trim, where decorative purposes are desired. 3. The perforated aluminum sheet, as its name implies, contains small holes or perforations throughout its surface. It frequently finds application in architectural scenarios, such as building facades or sunscreens, as well as in filtration systems. 4. The treadplate aluminum sheet, also known as checker plate or diamond plate, exhibits a raised pattern of lines or diamonds on its surface. This pattern enhances traction, making it suitable for industrial flooring or stair treads, where slip resistance is vital. 5. The anodized aluminum sheet undergoes an electrochemical process, forming a protective oxide layer on the surface. This process enhances durability, corrosion resistance, and allows for color customization through dye acceptance. Architectural applications, signage, and consumer products commonly employ anodized aluminum sheets. 6. The painted aluminum sheet, coated with a layer of paint, not only enhances appearance but also provides added corrosion protection. It is often utilized in applications where aesthetics are paramount, such as building facades, signage, or automotive parts. These examples represent a small selection of the aluminum sheet types available in the market. The selection of an appropriate type depends on specific project requirements, encompassing factors like durability, appearance, corrosion resistance, or slip resistance.

- Q: Are aluminum sheets suitable for electronic enclosures?

- Certainly, aluminum sheets are a fitting choice for electronic enclosures. Aluminum is extensively employed in the production of these enclosures owing to its exceptional characteristics. It possesses the advantage of being both lightweight and sturdy, ensuring optimal protection for electronic components. Moreover, aluminum exhibits excellent thermal conductivity, effectively dissipating heat generated by electronic devices. Additionally, it is non-magnetic and non-sparking, thereby guaranteeing safety and preventing interference with electronic signals. Furthermore, aluminum can be easily molded, machined, and finished, providing opportunities for customization and aesthetic appeal. All in all, aluminum sheets offer a dependable and cost-efficient solution for electronic enclosures.

Send your message to us

6061 aluminium polished thick plates 8-150mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords