6063 Aluminum Alloy Aluminium Profile Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of 6063 Aluminum Alloy Aluminium Profile Extrusion Description:

6063 Aluminum Alloy Aluminium Profile Extrusion (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the 6063 Aluminum Alloy Aluminium Profile Extrusion:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

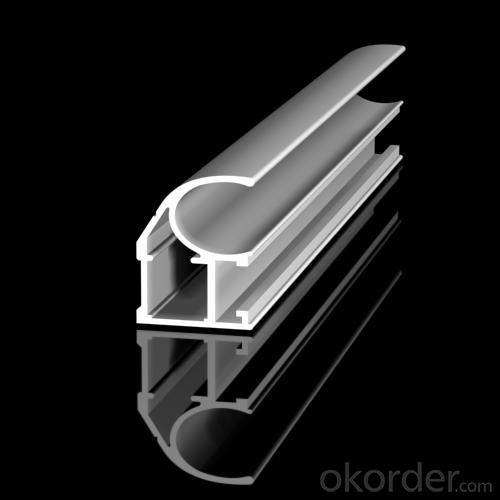

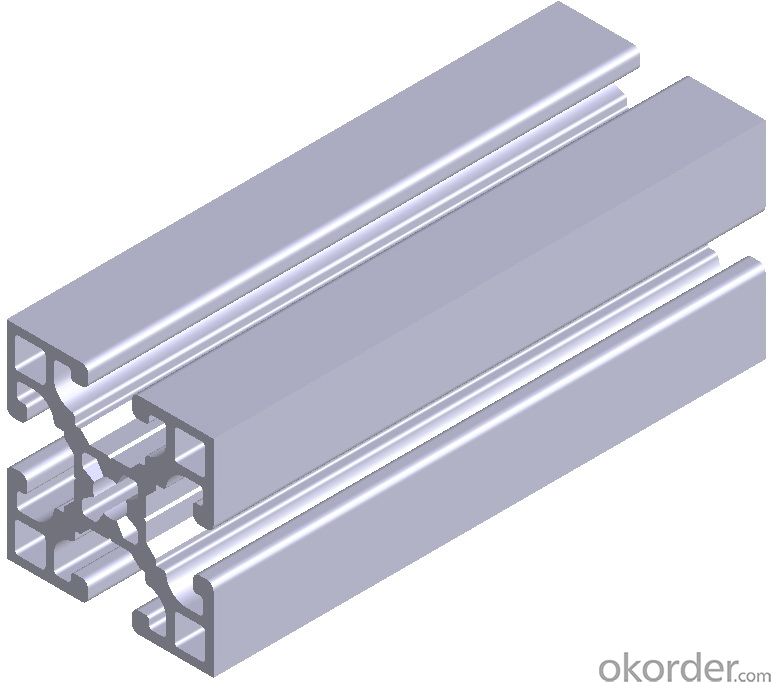

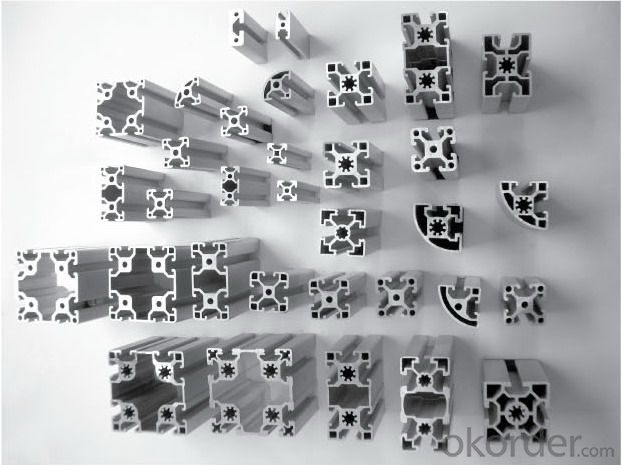

3.6063 Aluminum Alloy Aluminium Profile Extrusion Images:

4.6063 Aluminum Alloy Aluminium Profile Extrusion Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are aluminum coils used in the manufacturing of household appliances?

- Aluminum coils are used in the manufacturing of household appliances as they provide excellent conductivity, durability, and corrosion resistance. These coils are commonly used in appliances such as refrigerators, air conditioners, and heating systems. They help in transferring heat efficiently, improving energy efficiency, and ensuring the longevity of the appliance. Additionally, aluminum coils are lightweight, making them easier to handle during the manufacturing process.

- Q: I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- It does dissolve, but only slightly. It has a solubility of about 0.0001 under atmospheric pressure, it doesn't dissolve because the aluminium is extremely strongly bonded to oxygen, so it can't dissociate very much at all. If you want to dissolve aluminium oxide, you should use an alkaline solution.

- Q: Can aluminum coils be used for electrical conductivity purposes?

- Yes, aluminum coils can be used for electrical conductivity purposes. Aluminum is a good conductor of electricity and is often used in various electrical applications, including coils for transformers, motors, and generators.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a common material choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. Aluminum coils can efficiently transfer heat and withstand high temperatures, making them suitable for use in heat exchanger fins.

- Q: Can aluminum coils be used in heat sinks?

- Yes, aluminum coils can be used in heat sinks. Aluminum is a commonly used material for heat sinks due to its excellent thermal conductivity properties, which allow it to efficiently transfer heat away from the source. The coil shape helps to increase the surface area, enhancing heat dissipation.

- Q: How do aluminum coils contribute to lightweight construction?

- Aluminum coils contribute to lightweight construction by providing a material that is significantly lighter than other metals such as steel. This allows for the reduction of overall weight in structures, vehicles, and appliances, leading to increased fuel efficiency, improved performance, and lower environmental impact. Additionally, aluminum coils have high strength-to-weight ratio, making them ideal for applications where strength is required without compromising on weight.

- Q: Is it possible to use aluminum coil for creating a sculpture?

- <p>Yes, you can use aluminum coil to make a sculpture. Aluminum is a versatile material known for its strength, lightweight, and malleability, which makes it suitable for sculpting. It can be bent, twisted, and shaped into various forms. When working with aluminum coil, you can use tools like pliers, wire cutters, and a metal bender to manipulate the coil into the desired sculpture shape. Ensure you take safety precautions, such as wearing gloves and eye protection, due to the sharp edges and the risk of injury from handling metal.</p>

- Q: What is the impact of alloy purity on the performance of aluminum coils?

- The impact of alloy purity on the performance of aluminum coils is significant. Higher alloy purity leads to improved conductivity, strength, and corrosion resistance of the coils. It also enhances the overall efficiency and longevity of the coils. Conversely, lower alloy purity may result in reduced performance, lower conductivity, and increased susceptibility to corrosion. Therefore, ensuring high alloy purity is crucial for maximizing the performance and durability of aluminum coils.

- Q: What are the different surface textures available for aluminum coils?

- Aluminum coils offer a range of surface textures, each with its own distinctive qualities and uses. 1. Smooth: The smooth surface texture is a popular and versatile option for aluminum coils. It boasts a sleek and polished appearance, making it suitable for a wide array of applications, including architectural cladding, signage, and consumer electronics. 2. Stucco: Stucco texture involves embossing the aluminum coil to create a raised pattern reminiscent of small pebbles. This texture enhances the coil's durability, offering resistance against scratches and dents. It is often chosen for applications that require a robust and decorative finish, such as roofing, wall panels, and decorative trim. 3. Diamond: The diamond texture features an embossed diamond-shaped pattern on the aluminum coil's surface. This texture not only adds visual appeal but also provides enhanced traction and slip resistance, making it ideal for flooring, stairs, and ramps. 4. Brushed: The brushed texture is achieved by mechanically brushing the surface of the aluminum coil, resulting in a linear pattern. This finish gives the aluminum a distinctive satin-like appearance, making it sought after for architectural applications like interior wall cladding, furniture, and decorative elements. 5. Hammered: To create the hammered texture, the aluminum coil's surface is hammered, producing a unique and irregular pattern. This texture lends a rustic and handcrafted look, making it suitable for decorative accents, light fixtures, and furniture. 6. Perforated: The perforated texture involves puncturing small holes or perforations into the surface of the aluminum coil. This texture allows for increased airflow, light transmission, and sound absorption, making it commonly used in ventilation systems, acoustic panels, and decorative screens. These examples illustrate the various surface textures available for aluminum coils. The choice of texture depends on specific application requirements, including aesthetics, functionality, and durability.

- Q: Can aluminum coils be used in high-radiation environments?

- Yes, aluminum coils can be used in high-radiation environments. Aluminum has good radiation resistance and can withstand high levels of radiation without significant degradation or damage. It is commonly used in applications such as nuclear power plants and aerospace industries, where radiation exposure is a concern.

Send your message to us

6063 Aluminum Alloy Aluminium Profile Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords