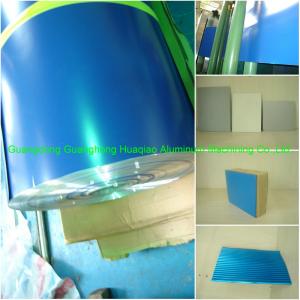

RAL 1032 PE 18 Micros Coated 6061 T6 Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

Product | RAL 1032 PE 18 Micros Coated Aluminium Coil | ||

Alloy | 1100, 1145, 1050, 1060, 1070, 3003, 3013, 3005, 3A21,4343,4045, 5052, 5082, 5083, 5086,6061, 8011 etc. | Temper | H12.H14.H16.H18.H22. H24.H26.H32.H34.H36. H38.O etc. |

Thickness | 0.2-7.0mm | Width | Until 2550 |

Painting items | PE and PVDF | Color | All Standards of RAL |

Coil weight | At clients’ requestments | MOQ | 5 tons |

Payment terms | 30% down payment 70% against B/L copy, L/C at sight | ||

Delivery time | 20-30 days after getting your down payment | ||

Package | Wooden Pallet (Customized packing ways are welcomed) | ||

Remarks | The special dimensions can be produced according to clients’ specification | ||

Application

Widely used in manufacturing of products as well as other industrial applications like:

Products Materials: PP cap stock, the traffic sign, air-conditioner heat and exchangers, food container, household foil, pharmaceutical packing, cigarettes packing etc.

Building Materials: aluminum curtain wall base plate, ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

- Q: i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum is a good conductor of electricity. If an object is completely encased in a conductor (forming a Faraday cage), the object will be shielded from radio waves. If the aluminum (or another conductor) covers only part of the object, radio waves may still reach it.

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: What is an aluminum coil?

- An aluminum coil is a long, flat, and thin piece of aluminum that is typically wound into a spiral shape. It is commonly used in various industries, such as construction, automotive, and electrical, due to its excellent corrosion resistance, lightweight nature, and high conductivity. Aluminum coils are often used for manufacturing products like gutters, roofing materials, heat exchangers, and electrical components.

- Q: Can aluminum coils be used in power generation facilities?

- Aluminum coils are indeed suitable for use in power generation facilities. Aluminum, being a highly conductive material, offers numerous benefits for power generation applications. Its exceptional thermal conductivity allows for efficient heat transfer from the coils, a critical factor in cooling systems within power generation facilities. Moreover, aluminum's lightweight nature simplifies handling and installation, setting it apart from metals such as copper. This lightweight attribute also contributes to cost savings by reducing overall equipment weight. Additionally, aluminum's corrosion resistance is particularly valuable in power generation facilities, which frequently operate in challenging environments. In conclusion, considering their conductivity, thermal efficiency, lightweight nature, and corrosion resistance, aluminum coils present a feasible choice for power generation facilities.

- Q: How do aluminum coils contribute to thermal insulation?

- Thermal insulation is enhanced by aluminum coils in multiple ways. Firstly, aluminum possesses a remarkable reflective property, enabling it to deflect heat and radiation away from the surface. This characteristic effectively reduces the amount of heat absorbed by the coil and transmitted to the surroundings. Additionally, aluminum coils are frequently employed in conjunction with insulation materials like foam or fiberglass. These insulating materials create air pockets that serve as a barrier against heat transfer. The aluminum coil acts as a safeguard, shielding the insulation material from any potential harm or compromise. Moreover, aluminum is a lightweight material that exhibits exceptional resistance to corrosion. This feature allows for the versatile use of aluminum coils in various applications, including HVAC systems, where they contribute to maintaining a consistent temperature by minimizing heat loss or gain. In summary, aluminum coils assume a critical role in thermal insulation by deflecting heat, safeguarding insulation materials, and imparting durability and longevity to the insulation system.

- Q: This question asks for an explanation of the various types of coatings that can be applied to aluminum coils.

- <p>Aluminum coils can be coated with several types of materials to enhance their properties for various applications. The main types include: 1. Anodized Coatings: These provide a protective oxide layer on the aluminum surface, enhancing corrosion resistance. 2. PVDF (Polyvinylidene Fluoride) Coatings: Known for their durability and resistance to UV rays, chemicals, and weathering. 3. Polyester Coatings: These are used for general-purpose applications due to their balance of properties like formability and chemical resistance. 4. PVF2 (Polyvinylidene Fluoride) Coatings: Similar to PVDF but with a thinner film, offering good weather resistance. 5. Acrylic Coatings: Known for their flexibility and adhesion, suitable for both interior and exterior applications. 6. Silane Coatings: Provide a thin, protective layer that enhances paint adhesion and corrosion resistance. Each type serves different purposes, and the choice depends on the specific requirements of the application.</p>

- Q: What are the potential health hazards associated with the use of old aluminum coils?

- <p>Using old aluminum coils can pose health risks due to potential leaching of aluminum into food or beverages. Long-term exposure to aluminum may lead to cognitive impairments and neurological issues. Additionally, old coils may have accumulated dirt, bacteria, or other contaminants that could cause infections or digestive problems. It's important to regularly inspect and replace aluminum cookware to ensure safety.</p>

- Q: I'm ball milling aluminum into powder and I have filled the canister with some water to prevent the aluminum from igniting. The powder has begun to dissolve in the water. I'd like to know the best way to remove the dissolved aluminum from the water so I can get to the powder.There is around of cup of water in the canister, just to give an idea of the situation.

- Boil the water. The water will evaporate, leaving the aluminum behind.

- Q: What are the common sizes of aluminum coils used in roofing?

- The sizes of aluminum coils commonly utilized in roofing can differ depending on the specific project's needs and requirements. Some well-liked sizes include widths of 24 inches, 36 inches, and 48 inches. These sizes are frequently selected due to their compatibility with standard roofing systems and their efficient coverage of a large surface area. Furthermore, the thickness of the aluminum coil can also vary, ranging from 0.019 inches to 0.032 inches. Ultimately, the size of the aluminum coil employed in roofing will be contingent upon factors such as the roof's size, desired aesthetic, and local building codes and regulations.

- Q: 11 g of aluminum at 200 C and 19 g of copper are dropped into 55 cm^3 of ethyl alcohol at 15 C. The temperature quickly comes to 24 C. What was the initial temperature of the copper? (answer in C) Express your answer using two significant figures.

- Example Problem Statement: An aluminum wing on a passenger jet is 29 m long when its temperature is 29°C. At what temperature would the wing be 7 cm (0.07 m) shorter? Step 1: Write down what you know in symbolic form: The wing is made of aluminum, therefore: α = 25 x 10-6 /oC Length: l = 29 m Temperature: T1 = 29 oC Change in length: Δl = -7 cm (-0.07 m) Step 2: Write down what you don't know in symbolic form: Temperature: T2 = ? oC Step 3: Find an equation that contains what you know and what you don't know: Δl = αlΔT = αl(T2 - T1) Step 4: Solve the equation for what you don't know: Δl = αl(T2 - T1); divide both sides by αl Δl/ αl = (αl/ αl )(T2 - T1) = T2 - T1; add T1 to both sides Δl/αl + T1 = T2 - T1 + T1 = T2 Δl/ αl + T1 = T2 Step 5: Plug in (substitute) what you know and you will find out what you don't know: Δl/ αl + T1 = T2 = (-0.07 m)/( 25 x 10-6 /oC x 29 m) + 29 oC = -96.551 oC + 29 oC = -67.551 oC = -67.6 oC rounded off.

Send your message to us

RAL 1032 PE 18 Micros Coated 6061 T6 Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords