6061 T6 Aluminum Plain Sheet for Construction and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

6061 T6 Aluminum Plain Sheet for Construction and Industry

l Product Introduction

Aluminium has a lot of salient properties that the other metals do not have. It is very strong, yet it is not very heavy. Like other metals, it conducts electricity and heat to a moderate degree. Most industries require aluminium sheets for various purposes. Aluminium can be easily beaten into sheets because of its high malleability. It has the preoperty of light weight, medium strength, easy-forming and anti-corrosion.

l Product Description

1)Alloy: 6061

2)Temper: H18 .H24 .H32 .H112 T4 T6 T651 O

3)Thickness: 0.2MM-20MM

4) Width : up to 1500mm

5) Good plasticity and conductivity

6) Dimensions can be produced as per clients' specifications

7) Generally used for industrial and construction applications

Product | Aluminum sheet |

Alloy | 1100 1050 1060 3003 3004 3105A 5005 5052 5754 5083 6061 6063 6082 8011 |

Temper | H14, H16, H18, H19, H24, H26,H32,H112,T4,T6,T651,O |

Width | 900—1500mm |

Thickness | 0.3—20mm |

Payment | L/C or T/T |

Packaging | Standard export packing |

Delivery time | In 20-30days after receiving L/C or T/T |

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

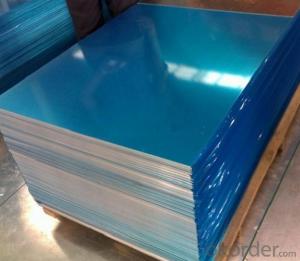

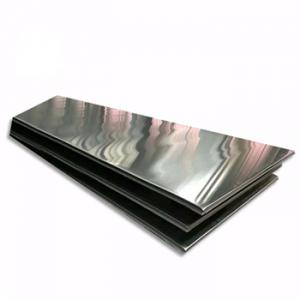

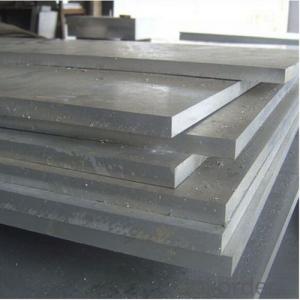

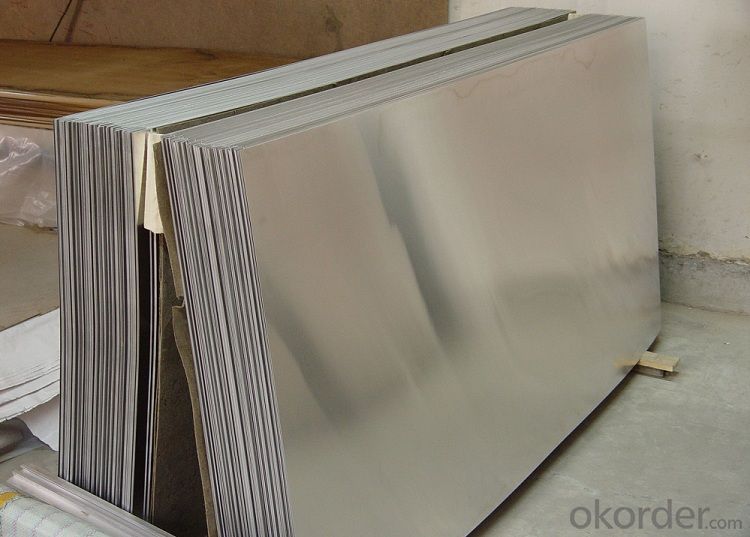

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is around 80 cents - 1$ per lb depending on grade. For current pricing you can try www.scrapmetalpricesandauctions.c...

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: Are aluminum sheets suitable for electrical applications?

- Yes, aluminum sheets are suitable for electrical applications. Aluminum is a highly conductive metal, and its use in electrical applications has become increasingly popular due to its numerous advantages. Firstly, aluminum is lightweight and offers excellent heat dissipation properties, making it an ideal choice for applications that require efficient thermal management. This is particularly important in electrical systems where heat can be generated, such as power transmission lines, electrical panels, and heat sinks. Secondly, aluminum sheets are highly corrosion-resistant. Unlike some other metals, aluminum forms a protective oxide layer on its surface, preventing further oxidation and corrosion. This makes it a reliable choice for electrical applications that are exposed to harsh environments or moisture. Additionally, aluminum is a cost-effective option compared to other metals commonly used in electrical applications, such as copper. It is readily available and has a lower price point, making it an attractive choice for manufacturers and consumers alike. However, it is important to note that aluminum has a lower electrical conductivity compared to copper. This means that for certain applications where high conductivity is crucial, such as in power transmission lines, copper may still be preferred. Nevertheless, advancements in technology and design have allowed aluminum to be used effectively in a wide range of electrical applications, from wiring and connectors to bus bars and transformers. In conclusion, aluminum sheets are indeed suitable for electrical applications, offering benefits such as lightweight construction, excellent thermal management, corrosion resistance, and cost-effectiveness. The final decision on whether to use aluminum or another material ultimately depends on the specific requirements and constraints of the electrical application in question.

- Q: Is it possible to use aluminum sheets in environments with low temperatures?

- <p>Yes, aluminum sheets can be used in cold climates. Aluminum has excellent corrosion resistance and maintains its strength in low temperatures, making it suitable for use in cold environments. It does not rust or corrode easily, which is beneficial in harsh weather conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper installation and design considerations are necessary to account for these properties in cold climates.</p>

- Q: Can aluminum sheets be used for chemical distillation columns?

- Aluminum sheets are indeed applicable in chemical distillation columns. Due to its remarkable thermal conductivity, resistance to corrosion, and lightweight properties, aluminum is widely favored for constructing distillation columns. It is especially suitable for situations where process conditions are relatively gentle, like low-pressure distillation or distillation of non-reactive substances. Nonetheless, it is crucial to acknowledge that aluminum might not be suitable for all chemical distillations, specifically those involving corrosive or reactive substances. In such instances, alternative materials such as stainless steel or glass-lined steel may be more suitable to guarantee the durability and integrity of the column.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q: Are aluminum sheets suitable for food storage containers?

- Yes, aluminum sheets are suitable for food storage containers. Aluminum is a safe and durable material that is resistant to corrosion, making it ideal for storing and preserving food. It also has excellent heat conduction properties, allowing for even cooking and reheating.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.The square and the thickness are multiplied, and then multiplied by the density is the weight, and then by weight conversion on it

Send your message to us

6061 T6 Aluminum Plain Sheet for Construction and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords