6061 T4 ALUMINUM ALLOY SHEET IN STOCK THICKNESS 2MM -10MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Alumina

(2).Sulfates

(3).Niche compounds..

3. Feature of Aluminum

After falling to Earth, atmospheric shielding drastically reduces 26Al production, and its decay can then be used to determine the meteorite's terrestrial age. Meteorite research has also shown that 26Al was relatively abundant at the time of formation of our planetary system. Most meteorite scientists believe that the energy released by the decay of 26Al was responsible for the melting and differentiation of some asteroids after their formation 4.55 billion years ago.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

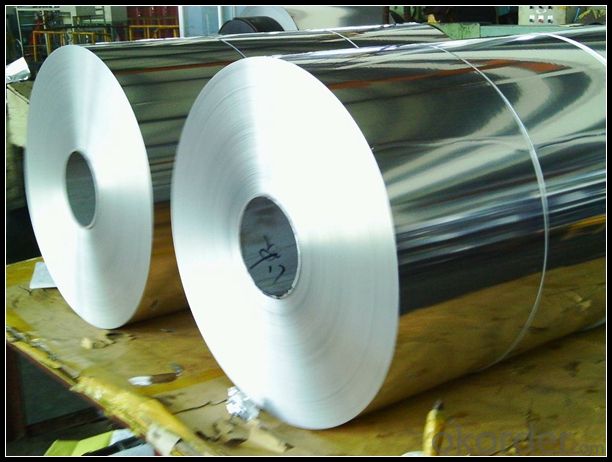

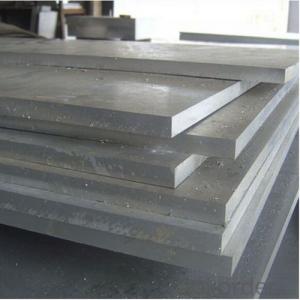

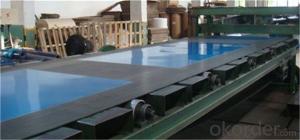

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Aluminium belt car

- Automobiles are machines of high speed. In order to give their performance the best, people prefer to improve their roads to adapt to cars rather than re - adapt them to bad roads. Now some people are interested in track cars, keen on retro, playing games and satisfying personal needs. 3 、 tracks are now used on slow tractors and tanks. In order to improve the speed of the military, or the use of wheeled armored personnel carriers.

- Q: Which is better, an aluminum belt excavator or a tire excavator?

- Crawler for complex terrain, strong applicability and maneuverability is weak; tire flexibility, can be a wide range of mobile operations, operations such as cement or asphalt pavement crawler excavator can not enter, but only suitable for light duty work

- Q: Explain the distinctions between aluminum sheets and aluminum strips.

- <p>Aluminum sheets and aluminum strips are both flat aluminum products, but they differ in width and thickness. Aluminum sheets are wider and can range from 0.2mm to 500mm in thickness, suitable for applications requiring broad surfaces like construction and packaging. Aluminum strips, on the other hand, are narrower and typically used in applications that require thin, elongated pieces, such as in electrical conduits or mechanical parts. The production processes may also vary, with sheets often being rolled and strips being extruded or rolled as well, depending on the specific application and desired properties.</p>

- Q: Aluminum band treble sounds good?

- The high pitched sound field of an aluminum band is shaped by a longitudinal distribution, so it is good to remove the axle.

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: What kind of aluminum strip is most suitable for use as exterior trim, considering factors like durability and weather resistance?

- <p>The best type of aluminum strip for exterior trim is typically one made from high-quality aluminum alloy, such as 6063-T5 or 6061-T6. These alloys offer excellent strength, durability, and resistance to corrosion. They are also lightweight and can withstand various weather conditions without rusting or fading. Additionally, these aluminum strips often come with a protective coating or anodized finish, which enhances their resistance to UV rays, scratches, and other environmental factors. It's important to choose a strip that has been specifically designed for exterior use to ensure long-lasting performance.</p>

- Q: How can the aluminium band be welded to the steel shell?

- Welding method:1) to deal with the surface of the aluminum strip and steel shell surface oil and oxide skin.2) after the low temperature welding wire 303B Wei Odin flatto, then put between the aluminum strip and steel shell.3) the resistance is placed in the welding place where the flat 303B wire is welded.4) in the premise of high temperature continuous heating, 303B welding wire melting forming, bonding aluminum strip and steel shell.Welding attention method:1, resistance welding current output must be enough, otherwise the parent can not reach the temperature, welding wire will not be adhesive.2, the surface of the oxide film must be handled clean, so that the aluminum band is easy to glue, otherwise, the aluminum oxide film will hinder the welding line bonding aluminum belt.

- Q: This question asks for a comparison between standard aluminum strips and custom-made aluminum strips, highlighting their differences.

- <p>Standard aluminum strips are mass-produced with fixed dimensions and specifications, making them readily available and generally more affordable. They are suitable for common applications where specific requirements are not needed. On the other hand, custom-made aluminum strips are manufactured according to specific customer requirements, including size, shape, thickness, and alloy type. This customization allows for unique applications and better performance in specialized environments but may come at a higher cost and with longer lead times due to the bespoke manufacturing process.</p>

- Q: What are the distinctions between pure aluminum and its alloys?

- <p>Aluminum and aluminum alloys have distinct properties. Pure aluminum is a soft, lightweight metal with good thermal and electrical conductivity. It is highly reflective and resistant to corrosion. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance its strength, durability, and resistance to heat and wear. These alloys are stronger and more versatile than pure aluminum, making them suitable for a wide range of applications, from aerospace to construction.</p>

- Q: The user is asking whether they should hire a professional to install aluminum strip products or if they can do it themselves.

- <p>Whether to hire a professional or do it yourself depends on your experience and comfort level with DIY projects. If you are skilled in construction or have experience with similar installations, you may be able to install aluminum strip products yourself. However, if you lack the necessary skills or are unsure about the process, hiring a professional installer is recommended. Professionals have the expertise to ensure a proper and secure installation, which can save you time and potential complications down the line. Additionally, they can handle any unexpected issues that may arise during the installation process.</p>

Send your message to us

6061 T4 ALUMINUM ALLOY SHEET IN STOCK THICKNESS 2MM -10MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords