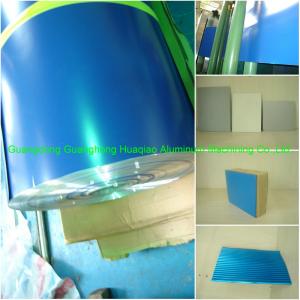

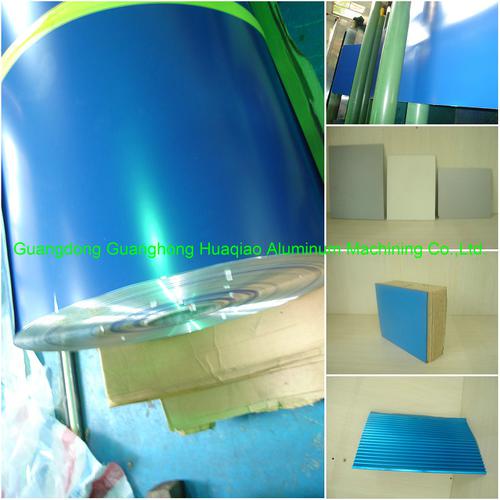

Blue Color Coated 6061 T6 Aluminum Alloy Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum coil is a material with excellentacid-resistance and alkali-resistance. The coating layer is even with brightcolor to last for a very long time. It is a green decoration material with thecharacters of environment protection, flame-resistance, and groovy colors. In nowadays, the color coated aluminum coil has become the popularmaterial for top grade decoration. With our advanceprofessional aluminum coated technique, we can custom various aluminum coils,like coated aluminum coil , Color coated aluminum coil , embossed aluminumsheet with the color and size which you demands.

1) Process: pre-treatment,continuous painting and baking for times .

2) Material: high qualitymaterial, aluminum sheets from South West Aluminum Industry Company in China,pre-treatment material from Henkel & Chemtell from Germany, more than 70%of PVDF coating from PPG Corp., the USA and polyester from Sweden BeckerIndustrial Coating Co., Ltd.

3) Our products can keepexcellent quality and stability.

4) Thickness: 0.06 - 1.0mm;width: 20 - 1,590mm

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

Applications:

The aluminum coils are widely used in ACP/curtain panel/honey combpanel/shutter/roofing and most of the decoration areas. With the superiorquality and advanced management, our products had been export to Euro/NorthAmerica /East Asia and many other areas and countries.

- Q: Can aluminum coils be used for marine applications?

- Aluminum coils possess the ability to be utilized in marine applications. Due to its superb resistance to corrosion within saltwater environments, aluminum is a favored material choice for such applications. The formation of a natural oxide layer on its surface provides protection against corrosion. The usage of aluminum coils is frequent in marine applications, including boat hulls, decks, and structures. Moreover, aluminum's lightweight nature enhances fuel efficiency and boosts performance within marine vessels. Its exceptional strength-to-weight ratio makes it the perfect selection for constructing boats and other marine equipment. However, it is crucial to carefully choose the appropriate grade of aluminum alloy, specifically designed for marine applications, to guarantee optimal performance and durability.

- Q: How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils are commonly used in HVAC systems as they serve as heat exchangers. These coils are responsible for transferring heat between the indoor and outdoor units of an HVAC system. The aluminum coils are designed to efficiently absorb heat from the indoor air and release it outside, or vice versa, depending on whether the system is in cooling or heating mode. The use of aluminum coils in HVAC systems ensures better heat transfer, corrosion resistance, and overall system performance.

- Q: This question asks for a comparison of various types of equipment used for welding aluminum coils, highlighting their distinct features and applications.

- <p>Aluminum coil welding equipment varies based on technology, power source, and application. TIG (Tungsten Inert Gas) welders are known for high-quality welds and are ideal for thin aluminum coils. MIG (Metal Inert Gas) welders are versatile and suitable for thicker coils, offering faster welding speeds. Stick welders are more portable and cost-effective but produce lower quality welds. Laser welders provide precise, deep penetration welds suitable for high-precision applications. Friction stir welding is a solid-state process that offers excellent joint properties without melting the metal. Each type has its advantages and is chosen based on the specific requirements of the welding task, such as material thickness, weld quality, and production rate.</p>

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils have excellent strength-to-weight ratio compared to many other metals. While aluminum is not as strong as steel, it is lighter and more flexible, making it a popular choice in various applications. Aluminum coils can withstand significant forces without breaking or deforming, making them suitable for a wide range of industries, including automotive, aerospace, and construction. Additionally, aluminum coils have good corrosion resistance, which further enhances their durability and longevity. However, it is important to note that the strength of aluminum can vary depending on the alloy and temper used, so specific comparisons should be made based on the particular application and requirements.

- Q: What are the advantages of using aluminum coils in HVAC systems?

- There are several advantages to using aluminum coils in HVAC systems. Firstly, aluminum coils offer excellent heat transfer properties, allowing for efficient cooling and heating of air. They also have a high resistance to corrosion, ensuring durability and longevity of the HVAC system. Additionally, aluminum coils are lightweight, making installation and maintenance easier. Finally, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice for HVAC systems.

- Q: What are the different packaging options available for aluminum coils?

- Customers have several packaging options to choose from for aluminum coils, depending on their specific needs and requirements. Some commonly used packaging options include: 1. Wooden crates: Sturdy wooden crates offer maximum protection for aluminum coils during transportation and storage. These crates are made of high-quality wood and designed to withstand rough handling, preventing coil damage. 2. Cardboard boxes: Smaller aluminum coils can be packaged in lightweight and cost-effective cardboard boxes. These boxes provide adequate protection against minor impacts and environmental factors. 3. Steel or aluminum skids: Aluminum coils can be placed on steel or aluminum skids for packaging. Skids provide a stable base and allow for easy handling using forklifts or pallet jacks. They are commonly used for larger coils or when transporting multiple coils together. 4. Stretch wrap: Stretch wrap is a popular choice for packaging aluminum coils. It offers excellent protection against dust, moisture, and scratches. The coils are tightly wrapped in plastic film, ensuring secure transportation. 5. Custom packaging: In certain cases, customers may require customized packaging solutions to meet specific requirements. This can include using protective covers, foam padding, or additional reinforcements to ensure safe handling and delivery of the aluminum coils. It is important to consider factors such as coil size, weight, transportation method, and intended use when choosing a packaging option. Working with a reputable packaging provider can help determine the most suitable packaging option for aluminum coils.

- Q: Is it safe and effective to use aluminum coil for baking purposes?

- <p>Yes, aluminum coil can be used for baking. It is a common material in baking due to its excellent heat conductivity, which allows for even heating and browning of baked goods. However, it's important to ensure that the aluminum coil is food-grade and clean to avoid any contamination. Additionally, some people may be concerned about potential health risks associated with aluminum, although these concerns are generally considered minimal when using aluminum cookware for baking.</p>

- Q: How do aluminum coils contribute to thermal insulation?

- Aluminum coils contribute to thermal insulation in several ways. Firstly, aluminum is a highly reflective material, meaning it can reflect heat and radiation away from the surface. This property helps to reduce the amount of heat that is absorbed by the coil and transferred to the surrounding environment. Additionally, aluminum coils are often used in conjunction with insulation materials such as foam or fiberglass. These insulating materials help to trap air pockets, which act as a barrier to heat transfer. The aluminum coil serves as a protective layer, preventing the insulation material from being damaged or compromised. Furthermore, aluminum is a lightweight material with excellent corrosion resistance. This allows aluminum coils to be used in various applications, including HVAC systems, where they can help to maintain a consistent temperature by minimizing heat loss or gain. Overall, aluminum coils play a vital role in thermal insulation by reflecting heat, protecting insulation materials, and providing durability and longevity to the insulation system.

- Q: Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum coils are lightweight, durable, and have excellent corrosion resistance, making them suitable for use in suspension systems. They provide better handling, improved ride quality, and enhance fuel efficiency in vehicles.

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The high thermal conductivity of aluminum allows for efficient heat transfer, making it an ideal material for heat exchangers. Additionally, aluminum's corrosion resistance ensures that the coils will remain durable and functional even in harsh environments.

Send your message to us

Blue Color Coated 6061 T6 Aluminum Alloy Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords