Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

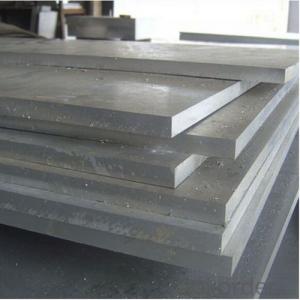

Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

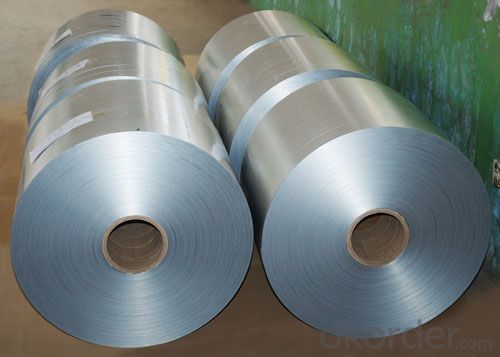

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

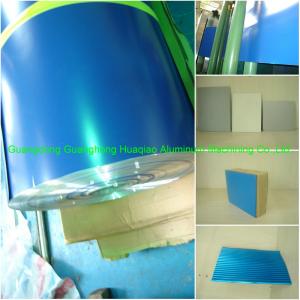

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be used in electrical conductors?

- Yes, aluminum coils can be used in electrical conductors. Aluminum is a highly conductive metal, second only to copper in terms of electrical conductivity. It possesses excellent electrical properties, making it suitable for use in various electrical applications, including the production of coils. Aluminum coils are commonly used in electrical conductors for applications such as transformers, motors, generators, and power transmission lines. They are lightweight, cost-effective, and offer good thermal conductivity. However, it is important to note that aluminum has a lower tensile strength compared to copper, so proper design considerations must be taken into account to ensure the coil's stability and durability. Additionally, aluminum coils may require larger cross-sectional areas compared to copper coils to achieve the same electrical performance.

- Q: What are the common sizes and dimensions of aluminum coils?

- The common sizes and dimensions of aluminum coils vary depending on the specific application and industry requirements. However, some commonly used sizes include widths ranging from 2 inches to 60 inches and thicknesses ranging from 0.008 inches to 0.25 inches. The length of the coils can vary as well, depending on the customer's needs.

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum has excellent thermal conductivity, making it an efficient choice for heat transfer applications in power generation equipment such as heat exchangers and condensers. Additionally, aluminum's lightweight nature and corrosion resistance make it a viable option for various power generation processes, including wind turbines and hydroelectric power plants.

- Q: How to calculate the weight of strips with the weight of aluminum coil known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width).Ps: Keep unit the same.

- Q: This question asks for a brief overview of the characteristics that define aluminum coil.

- <p>Aluminum coil possesses several key properties: high strength-to-weight ratio, making it lightweight yet strong; excellent corrosion resistance due to its natural oxide layer; good thermal and electrical conductivity, which is beneficial for heat exchangers and electrical applications; high reflectivity, useful in applications like reflective insulation; and good formability, allowing it to be easily shaped and bent. It's also non-magnetic and has low thermal expansion, which is advantageous in precision applications. Additionally, aluminum coil is recyclable and environmentally friendly, contributing to its popularity in various industries.</p>

- Q: What specific cleaning procedures should be followed for aluminum coils post-usage to ensure their longevity and functionality?

- <p>After using aluminum coils, it's important to clean them properly to maintain their performance and longevity. Typically, a mild detergent and warm water solution can be used to gently clean the coils. Avoid abrasive materials or harsh chemicals that could scratch the surface. Rinse thoroughly to remove all detergent residues. For stubborn residues, a soft cloth or sponge can be used. It's also crucial to dry the coils completely to prevent corrosion. Regular inspection and maintenance, including cleaning, will help extend the life of aluminum coils.</p>

- Q: This question asks for a method to calculate the diameter of an aluminum coil using its weight and density.

- <p>To calculate the diameter of an aluminum coil based on its weight and density, you first need to know the volume of the coil. The formula for volume (V) is V = mass (m) / density (蟻). Once you have the volume, you can use the formula for the volume of a cylinder, V = 蟺r虏h, where r is the radius and h is the height (or length) of the coil. If you know the height of the coil, you can solve for the radius and then double it to find the diameter (D = 2r). Ensure you have consistent units for all measurements. This calculation assumes the coil is cylindrical and uniform in thickness.</p>

- Q: What are the different alloys used in aluminum coils?

- Aluminum coils are made using various alloys, each possessing unique properties and applications. Some commonly employed alloys include: 1. 3003: Renowned for its exceptional formability and resistance to corrosion, this alloy finds frequent use in applications requiring moderate strength, such as automotive components, storage tanks, and kitchen utensils. 2. 5052: An alloy characterized by its versatility, good corrosion resistance, high fatigue strength, and excellent weldability. It is commonly utilized in the production of aircraft fuel tanks, marine components, and architectural applications. 3. 6061: Distinguished by its high strength and excellent machinability, 6061 is often employed in structural components like frames and braces. It also offers good corrosion resistance, making it a popular choice in the aerospace and automotive industries. 4. 8011: Primarily used in the packaging industry, particularly for manufacturing aluminum foil. This alloy provides good formability, high tensile strength, and excellent resistance to moisture and chemicals. 5. 1100: A commercially pure aluminum alloy, prized for its high electrical and thermal conductivity. It is commonly utilized in electrical wiring, heat exchangers, and lighting fixtures. These examples represent only a fraction of the alloys available for aluminum coils, as there are numerous other variations tailored to specific requirements and applications. The choice of alloy depends on several factors, such as desired strength, corrosion resistance, formability, and cost considerations.

- Q: What are the different types of aluminum coils?

- Aluminum coils come in a variety of types, each with its own unique properties and uses. Let's take a look at some common examples: 1. Pure Aluminum Coils: Made from pure aluminum, these coils find applications in packaging, construction, and automotive industries. 2. Textured Aluminum Coils: These coils have a surface with texture or patterns, adding aesthetic appeal and providing grip or anti-slip properties. They are commonly used in architectural designs, signage, and decorative applications. 3. Coated Aluminum Coils: These coils have a protective coating applied to the surface, offering enhanced durability, weather resistance, and aesthetic customization. They are often used in building facades, roofing, and cladding systems. 4. Anodized Aluminum Coils: Through an electrochemical process called anodization, a layer of oxide is formed on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized aluminum coils are commonly used in architectural applications, electronics, and automotive parts. 5. Pre-painted Aluminum Coils: With a layer of paint applied to the surface, these coils provide protection against weathering and add color aesthetics. They are frequently used in the construction industry for roofing, siding, and insulation purposes. 6. Stucco Patterned Aluminum Coils: These coils have a raised pattern resembling stucco, adding texture and strength to the aluminum. They are commonly used in refrigerators, air conditioners, and other appliances. 7. Clad Aluminum Coils: These coils consist of two or more layers of aluminum bonded together, offering enhanced strength, durability, or specific properties. They find applications in industries such as aerospace, defense, and transportation. In summary, the choice of aluminum coil type depends on specific application requirements, including appearance, corrosion resistance, durability, and mechanical properties.

- Q: How can you tell the difference between aluminum and other non-magnetic metals, such as what I've heard called, pot-metal?

- Aluminum is very light. Pot metal, also known as white metal, die-cast zinc, or monkey metal,[1] is a slang term that refers to alloys that consist of inexpensive, low-melting point metals used to make fast, inexpensive castings. There is no scientific metallurgical standard for pot metal; common metals in pot metal include zinc, lead, copper, tin, magnesium, aluminium, iron, and cadmium. The primary advantage of pot metal is that it is quick and easy to cast. Due to its low melting temperature no sophisticated foundry equipment is needed and specialized molds are not necessary. It is sometimes used to experiment with molds and ideas before using metals of higher quality. Examples of items created from pot metal include toys, furniture fittings, tool parts, electronics components, and automotive parts.[citation needed] Pot metal can be prone to instability over time, as it has a tendency to bend, distort, crack, shatter, and pit with age.[1] The low boiling point of zinc and the fast cooling of the newly-cast part often allow air bubbles to remain within the cast part, weakening the metal.[1] Many of the components of pot metal are susceptible to corrosion from airborne acids and other contaminants, and the internal corrosion of the metal often causes the decorative plating to flake off.[citation needed] Pot metal is not easily glued, soldered or welded.[1] At one time, pot metal referred to a copper alloy that was primarily alloyed with lead. 67% Cu, 29% Pb 4% Sb and 80% Cu, 20% Pb were common formulations.[2] The primary component of pot metal is zinc, but often the caster adds other metals to the mix to strengthen the cast part, improve the flow of the molten metal, or to reduce cost.[dubious – discuss] With a low melting point of 419 °C (786 °F), zinc is often alloyed with other metals including lead, tin, aluminium and copper.

Send your message to us

Flat Rolled Aluminum Coil Ohio - Alloy 6061 T6 China Distributor 2mm 3mm 4mm Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords