3003 6061 7005 7075 T6 Aluminum Sheets / 7075 T6 Aluminum Sheet Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Standard: | ASTM/DIN/GB/SUS |

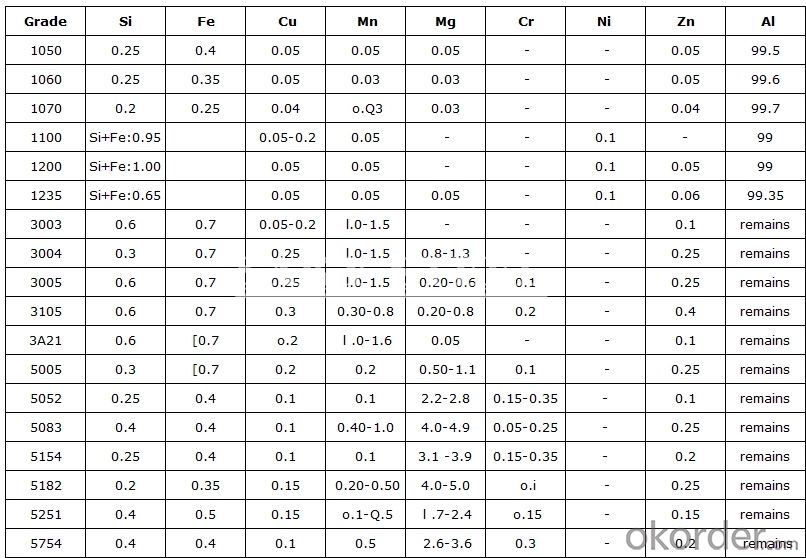

2. Grade: | 1000, 2000, 3000, 4000, 5000, 6000series a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. d) 4000 Series: 4045, 4047, 4343, etc. e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. f) 6000 Series: 6061, 6063, 6082, 6A02, etc. |

3. Surface: | Mill, Bright,Polished,Hairline, Embossed,etching |

4.Temper: | H32 H34 H36 H111 H112 H116 |

5.Thickness: | 0.02mm ~ 350mm |

6.Width: | 10mm ~ 2500mm |

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: Can you make tank armor using Aluminium, Polymers, Styrofoam, Explosive Reactive Armor to stop NATO DP rounds and/or HEAT rounds maybe RPG-7?

- Aluminium has a strength up to 800 N/mm2 (for its best Al-based alloys) while steels can go much higher... about 1400 N/mm2 if I recall well. The problem with aluminium is that is prompt to fatigue break which is not good with something vibrating like a rolling tank armor. Polymers are not strong enough unless you use composite materials, for ex. fibre glass or even better - carbon fibre reinforced. The problem is still that unlike steel, the strength is exceptionally high... in one direction - so pray for the impact to be mostly from this direction.

- Q: A 15.1 g aluminum block is warmed to 53.2 °C and plunged into an insulated beakercontaining 32.6 g of water initially at 24.4 °C. The aluminum and the water are allowed to cometo thermal equilibrium.Assuming that no heat is lost, what is the final temperature of the water and aluminum?

- To solve this problem, you need the heat capacity of water and Al, I know off hand the heat capacity of water but you'll need to look it up for Al. From the problem, you know that the heat given up as the aluminum cools is gained by the water heating up. As there is no phase change, the heat gained (or lost) is mass * heat capacity * temperature change energy gained by water = energy lost by Al. Let Tf be the final temperature of the Al and water. 32.6 g * 4.18 J/gK * (Tf - 24.4C) = 15.1 g * heat capacity of Al * (53.2 C - Tf) Solve for Tf. Because there is almost twice as much water as Al and water has a higher heat capacity than Al, the temperature will be closer to 24.4C than it is to 53.2C

- Q: Can aluminum sheet be welded?

- Indeed, welding aluminum sheet is feasible. Aluminum, a versatile metal, lends itself well to welding through the utilization of diverse techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). Nevertheless, the welding of aluminum necessitates specific considerations due to its elevated thermal conductivity and low melting point when compared to other metals. Consequently, selecting the suitable welding process, filler material, and shielding gas is crucial to ensuring a successful weld. Moreover, proper surface preparation, including thorough cleaning and the removal of any oxide layer, plays a pivotal role in achieving a robust and long-lasting weld in aluminum sheet.

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery due to their high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. Additionally, aluminum is easy to fabricate, making it a popular choice for various applications in the industrial sector.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods include mechanical abrasion, chemical etching, and surface treatments such as anodizing or conversion coating. Mechanical abrasion involves roughening the surface of the aluminum sheet using sandpaper or other abrasive materials to improve adhesion. Chemical etching involves using acid or alkaline solutions to create a textured surface on the aluminum sheet. Surface treatments such as anodizing or conversion coating involve applying a protective layer or coating to the aluminum sheet to enhance adhesion. Ultimately, the choice of surface preparation method depends on the specific requirements of the adhesive bonding process and the type of adhesive being used.

- Q: What is the standard size of an aluminum sheet?

- Depending on the specific application and industry, the standard size of an aluminum sheet may vary. However, typically, aluminum sheets come in commonly found standard sizes such as 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are extensively used in various industries like construction and manufacturing due to their adaptability and compatibility with standard equipment and processes. Nevertheless, it is crucial to acknowledge that aluminum sheets can also be personalized by cutting or ordering them in different sizes to fulfill specific project necessities.

- Q: Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 1220°F (660°C) and excellent heat transfer properties, making it suitable for various applications that involve exposure to high temperatures.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Can aluminum sheets be used for flooring?

- Indeed, flooring can utilize aluminum sheets. Lightweight and sturdy, aluminum proves resistant to corrosion, rendering it an appropriate option for a range of flooring uses. Notably, aluminum sheets frequently find employment in industrial, commercial, and residential settings, encompassing warehouses, garages, kitchens, and outdoor areas. These sheets offer commendable strength, effortless installation, and minimal upkeep. Furthermore, aluminum flooring imparts a polished and contemporary aesthetic to any given space. Nevertheless, prudent consideration of factors like thickness, finish, and the unique demands of the flooring project becomes imperative prior to settling on aluminum sheets.

Send your message to us

3003 6061 7005 7075 T6 Aluminum Sheets / 7075 T6 Aluminum Sheet Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords