6061-T6 Aluminum Coil for Roofing, Wall and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil for Roofing Wall and Decoration

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

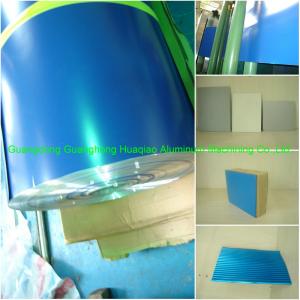

2. Application of Color Coated Aluminium Coils for Aluminum Roller Shutter 0.15 to 1.20mm

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil for Roofing Wall and Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

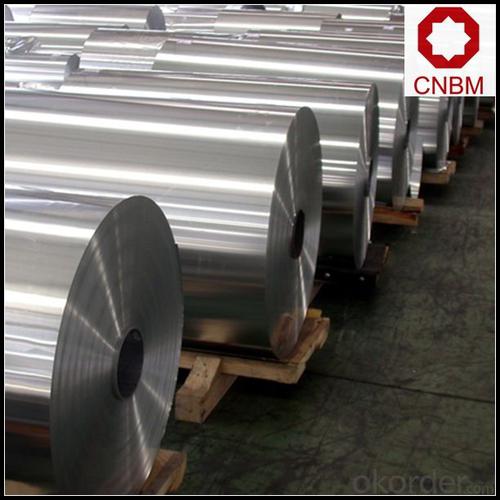

5. Image of Aluminum Coil for Roofing Wall and Decoration

6. Package and shipping of Aluminum Coil for Roofing Wall and Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils depends on various factors such as the specific application, geometry of the coil, and the surrounding conditions. However, in general, aluminum has a relatively high thermal conductivity, making it an efficient conductor of heat. For forced convection applications, where a fluid such as air or water is used to transfer heat, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as the flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This lower coefficient is due to the slower movement of air and the reduced heat transfer effectiveness compared to forced convection. It is important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q: Can aluminum coils be used in explosive environments?

- No, aluminum coils cannot be used in explosive environments as aluminum is not intrinsically safe and can ignite or cause sparks in the presence of flammable or explosive gases.

- Q: What are the different joining methods for aluminum coils?

- Depending on the specific application and desired bond strength, there are multiple methods available for joining aluminum coils. Some commonly used techniques include: 1. Welding: TIG welding, MIG welding, and laser welding are all viable options for welding aluminum coils. These methods create a robust and long-lasting bond that ensures structural integrity. 2. Brazing: By melting a copper-based alloy filler material, two aluminum coils can be joined together. Brazing is particularly useful for joining thin aluminum coils and provides a strong and leak-proof connection. 3. Adhesive bonding: This non-destructive method involves using a high-strength adhesive to bond the aluminum coils. Adhesive bonding is often preferred for applications where aesthetics and surface finish are vital, as it does not leave any visible welding or brazing marks. 4. Mechanical joining: Techniques such as riveting, clinching, and using fasteners like screws or bolts are categorized under mechanical joining. These methods offer a reliable and easily reversible bond, making them suitable for applications that require disassembly. 5. Roll bonding: Roll bonding is a process that involves passing two or more aluminum coils through a rolling mill under high pressure, resulting in the creation of a single composite coil. This method is commonly employed for joining dissimilar metals or creating laminated structures with different alloy combinations. Each joining method has its own advantages and limitations, and the choice depends on factors such as desired strength, cost, production volume, and specific application requirements. It is crucial to carefully consider these factors to ensure the most appropriate method is selected for aluminum coil applications.

- Q: What are the common surface protection methods for aluminum coils?

- Various industries widely use several common methods for protecting the surface of aluminum coils. These methods aim to ensure the long-term durability and performance of the coils by preventing corrosion and other types of damage. Anodizing is one of the most common surface protection methods for aluminum coils. It involves immersing the coil in an electrolyte bath and applying an electric current to create a protective oxide layer on the surface. This oxide layer not only improves the appearance of the coil but also enhances its resistance to corrosion, scratching, and wear. Coating is another popular method for protecting the surface of aluminum coils. It involves applying a layer of paint or coating material onto the coil's surface. Coatings can be applied using various techniques, such as electrostatic spraying, roll coating, or coil coating. These coatings act as a barrier between the aluminum surface and external elements, safeguarding it from moisture, UV radiation, and other environmental factors that can cause corrosion and damage. Protective films also offer a way to protect aluminum coils. These films, typically made from polyethylene or similar materials, are applied as a temporary protective layer. They help prevent scratches, abrasions, and other types of damage during transportation, storage, and installation. When it's time to use the aluminum coil, the protective film can be easily peeled off, leaving behind a clean and undamaged surface. Proper storage and handling practices are also crucial for protecting aluminum coils. Storing the coils in a dry, clean, and well-ventilated area, away from corrosive substances, can significantly extend their lifespan. Additionally, handling the coils with care and using appropriate lifting and transportation equipment can prevent physical damage that could compromise their integrity. In conclusion, the common methods for protecting the surface of aluminum coils include anodizing, coating, the use of protective films, as well as proper storage and handling practices. By employing these methods, aluminum coils can be effectively safeguarded against corrosion, scratching, and other forms of damage, ensuring optimal performance and longevity.

- Q: What are the different types of alloys used for aluminum coils?

- There are several different types of alloys that are commonly used for aluminum coils. The most commonly used alloy for aluminum coils is 3003. This alloy is known for its excellent corrosion resistance and moderate strength. It is often used in applications where high strength is not required, such as in roofing and siding. Another commonly used alloy for aluminum coils is 5052. This alloy has good weldability and formability, making it suitable for a wide range of applications. It is often used in the automotive industry for body panels and fuel tanks. 6061 is another popular alloy for aluminum coils. This alloy has excellent strength and is often used in structural applications. It is commonly used in the aerospace industry for aircraft parts and in the construction industry for structural components. Other alloys that are used for aluminum coils include 1100, 5005, and 8011. Each of these alloys has its own unique properties and characteristics, making them suitable for different applications. For example, 1100 is known for its high electrical conductivity and is often used in electrical applications, while 8011 is commonly used for packaging and food containers due to its excellent corrosion resistance. In summary, the different types of alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys offer a range of properties and characteristics that make them suitable for various applications across industries such as automotive, aerospace, construction, and packaging.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is known for its lightweight and corrosion-resistant properties, which make it suitable for various applications, including those in high-altitude environments. Additionally, aluminum has a high strength-to-weight ratio, allowing it to withstand the challenges posed by high altitudes.

- Q: Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction.However, isn't aluminium oxide an amphoteric oxide that can react with both acids and alkalis?

- Like hell, it can.

- Q: How do aluminum coils contribute to noise reduction?

- Aluminum coils contribute to noise reduction in several ways. Firstly, aluminum is a lightweight material that can effectively absorb and dampen sound waves. When used in coils, it can help to reduce vibrations and minimize the transmission of noise. Additionally, aluminum has excellent thermal conductivity properties, which can help dissipate heat and prevent temperature-related noises. This is especially important in HVAC systems where the noise generated by the equipment can be significant. Furthermore, aluminum coils can be designed with special features such as grooves or fins that enhance their noise reduction capabilities. These features help to increase the surface area of the coil, allowing for better heat transfer and reducing noise levels. Overall, aluminum coils provide an efficient and effective solution for noise reduction in various applications, making them a popular choice in industries where noise control is crucial.

- Q: Can aluminum coils be used in automotive applications?

- Automotive applications can indeed utilize aluminum coils. Given their lightweight nature, aluminum coils prove to be an exceptional option for automotive manufacturers, aiding in the reduction of overall vehicle weight. Consequently, this reduction can lead to enhanced fuel efficiency and performance. In addition, the outstanding heat conductivity of aluminum coils becomes indispensable in automotive applications, particularly when it comes to heat dissipation. Furthermore, the commendable corrosion resistance of aluminum coils proves to be highly advantageous in automotive applications, specifically when vehicles are exposed to diverse weather conditions and road salts. All in all, the utilization of aluminum coils in automotive applications offers numerous benefits, including weight reduction, improved fuel efficiency, superior heat dissipation, and enhanced corrosion resistance.

Send your message to us

6061-T6 Aluminum Coil for Roofing, Wall and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords