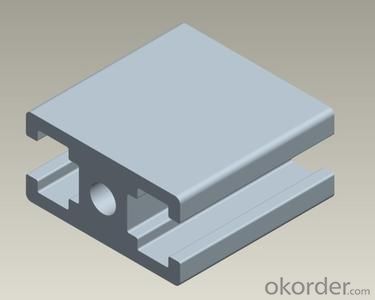

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

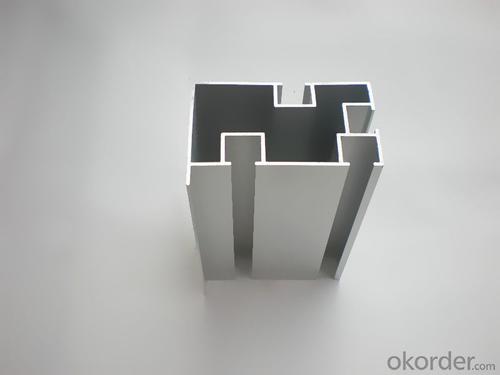

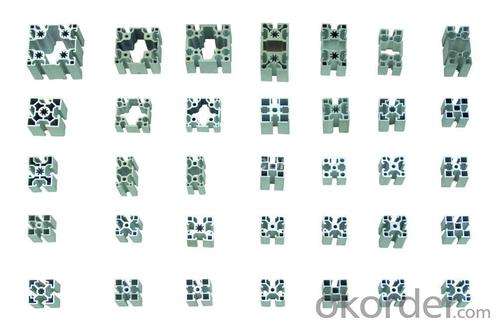

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Can aluminum profiles be anodized for improved corrosion resistance?

- Aluminum profiles can undergo anodization to enhance their resistance to corrosion. Anodizing involves an electrochemical process that creates a protective layer of aluminum oxide on the metal's surface. This layer not only improves the appearance of the profile but also provides excellent corrosion resistance. During anodization, the aluminum profile is placed in an electrolytic solution and subjected to a direct current. This prompts oxidation to take place on the metal's surface, resulting in the formation of a thick layer of aluminum oxide. This oxide layer is tough, long-lasting, and firmly adheres to the underlying aluminum, effectively guarding against corrosion. The anodic oxide layer can be further fortified by sealing it using different methods, such as hot water sealing or chemical sealing. This serves to enhance the aluminum profile's resistance to environmental elements like moisture, chemicals, and UV radiation. Anodized aluminum profiles offer numerous advantages over non-anodized ones. They exhibit superior resistance to corrosion, scratches, and wear. Moreover, anodization can also create a decorative finish for the aluminum profile, as it allows for a wide array of colors to be applied. In conclusion, anodization is an extremely effective technique for boosting the corrosion resistance of aluminum profiles, making them suitable for various applications where protection against corrosion is crucial. These applications include the construction, automotive, aerospace, and electronics industries.

- Q: Are aluminum profiles suitable for material handling equipment?

- Yes, aluminum profiles are suitable for material handling equipment. Aluminum profiles offer several advantages that make them an ideal choice for material handling applications. Firstly, aluminum is lightweight yet strong, which makes it easier to handle and transport materials. This is especially beneficial for equipment that needs to be maneuvered or transported frequently. Secondly, aluminum profiles have excellent corrosion resistance properties, making them suitable for both indoor and outdoor material handling applications. This durability ensures that the equipment can withstand harsh environments and maintain its structural integrity over time. Additionally, aluminum profiles can be easily customized and assembled to create various types of material handling equipment, such as carts, conveyors, and shelving systems. The versatility of aluminum profiles allows for flexibility in design and adaptability to different material handling requirements. Furthermore, aluminum is a sustainable material as it is 100% recyclable. Choosing aluminum profiles for material handling equipment aligns with environmentally friendly practices and reduces the carbon footprint. In summary, aluminum profiles are indeed suitable for material handling equipment due to their lightweight yet strong nature, corrosion resistance, versatility in design, and sustainability.

- Q: Can aluminum profiles be used in display stand and podium manufacturing?

- Yes, aluminum profiles can definitely be used in display stand and podium manufacturing. Aluminum is a highly versatile and durable material that offers several advantages such as lightweight, corrosion resistance, and easy customization. It can be easily shaped and fabricated into various designs and sizes, making it suitable for creating aesthetically appealing and functional display stands and podiums. Additionally, aluminum profiles can also be an excellent choice for portable or temporary setups due to their portability and easy assembly.

- Q: Are aluminum profiles suitable for electrical conductivity applications?

- Electrical conductivity applications are not suitable for aluminum profiles. Despite aluminum being a proficient conductor of electricity, the presence of an oxide layer on the surface of aluminum profiles typically obstructs electrical conductivity. Furthermore, aluminum profiles are susceptible to corrosion, ultimately affecting their conductivity. Consequently, materials with superior conductivity attributes like copper or silver are generally favored for electrical conductivity applications.

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the field of commercial construction.

- <p>Commonly used aluminum profiles in commercial construction include: 1. Extruded aluminum profiles, which are versatile and can be customized for various applications. 2. Structural aluminum framing, used for building structures and curtain walls. 3. Aluminum window and door frames, known for their durability and energy efficiency. 4. Aluminum handrails and railings, important for safety in commercial buildings. 5. Aluminum trusses, used for roof structures and large spans. 6. Aluminum angles and channels, used for support and framing. 7. Aluminum tubes, used in various structural and decorative applications. These profiles are chosen for their strength, lightweight, corrosion resistance, and ease of maintenance.</p>

- Q: Can aluminum be utilized as a material for constructing railings and fences?

- <p>Yes, aluminum profiles are commonly used for railings and fences due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be powder-coated in various colors to match architectural styles. Aluminum railings and fences are also appreciated for their strength and ability to withstand harsh weather conditions without rusting or rotting, making them a popular choice for both residential and commercial applications.</p>

- Q: Is it possible to utilize aluminum profiles as a component in systems designed for covering interior walls?

- <p>Yes, aluminum profiles can be used for interior wall cladding systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. Aluminum profiles are easy to install and can be used in conjunction with various materials such as glass, stone, or wood to create a sleek and modern look. They are also customizable, allowing for a wide range of design options and can be powder-coated or anodized for different finishes and colors to match any interior design scheme.</p>

- Q: Are aluminum profiles suitable for food processing or storage facilities?

- Yes, aluminum profiles are suitable for food processing or storage facilities. Aluminum is a highly versatile material that offers several advantages in these environments. Firstly, aluminum is corrosion-resistant, ensuring that it remains unaffected by moisture, food acids, or cleaning agents commonly used in food facilities. This makes it ideal for use in areas where hygiene and cleanliness are crucial. Secondly, aluminum profiles are lightweight yet sturdy, making them easy to handle and install. This is especially beneficial in food processing facilities where regular equipment maintenance and reconfigurations are required. Additionally, aluminum is a non-toxic material, ensuring that it does not contaminate food products during processing or storage. It is also an excellent conductor of heat, allowing for efficient temperature control in processing facilities. Furthermore, aluminum profiles can be easily cleaned and sanitized, reducing the risk of bacterial growth and ensuring compliance with food safety regulations. Overall, the durability, corrosion resistance, lightweight nature, non-toxicity, and ease of maintenance make aluminum profiles an excellent choice for food processing or storage facilities.

Send your message to us

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords