Customized Aluminum Extrusion Profiles - Aluminum 6063 T6 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

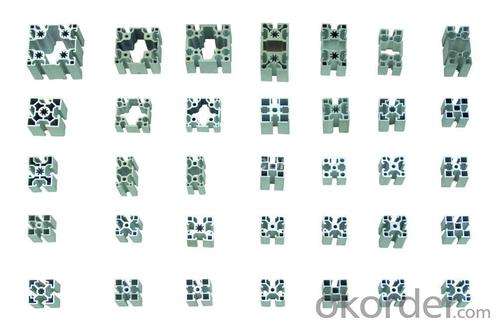

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Can aluminum profiles be used for display cases or cabinets?

- Yes, aluminum profiles can definitely be used for display cases or cabinets. Aluminum profiles are lightweight, durable, and have a sleek, modern appearance which makes them a popular choice for displaying products or storing items in cabinets. They can be easily customized and come in various sizes and shapes to meet specific design requirements. Additionally, aluminum profiles are corrosion-resistant, making them suitable for both indoor and outdoor applications. They also offer excellent thermal conductivity, which can be beneficial for controlling temperature in display cases or cabinets. Overall, aluminum profiles provide a versatile and attractive solution for creating display cases or cabinets.

- Q: What are the different bending radius options for aluminum profiles?

- The bending radius options for aluminum profiles can vary depending on the specific profile design and thickness. However, in general, common bending radius options for aluminum profiles range from 1.5 times the profile thickness to 3 times the profile thickness.

- Q: This question asks about the various types of surface treatments or finishes that can be applied to aluminum profiles.

- <p>Aluminum profiles can be coated with different types of finishes to enhance their appearance, durability, and resistance to corrosion. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a durable and colorful finish applied through an electrostatic process. 3. Electrophoretic coating, a method that uses electric current to apply a paint-like coating. 4. PVDF coating, a high-performance finish with excellent weather resistance. 5. Thermal spraying, which applies a coating through a high-velocity flame. 6. Vacuum coating, a process that deposits thin layers of material in a vacuum chamber. Each type of coating has specific properties and applications, making them suitable for different environments and uses.</p>

- Q: What are the different types of surface protection for aluminum profiles?

- There are several different types of surface protection options available for aluminum profiles. These options are designed to enhance the durability and aesthetics of the aluminum profiles and provide protection against various environmental factors. 1. Anodizing: Anodizing is one of the most common methods of surface protection for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance and can be done in various colors. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profiles, which is then cured under heat to form a protective layer. Powder coating offers a wide range of color options, excellent durability, and resistance to scratching, chipping, and fading. 3. Paint: Painting is another option for surface protection of aluminum profiles. It involves applying a liquid paint coating to the surface, which provides both protection and aesthetic enhancement. Paint can be customized in terms of color, texture, and finish, but it may not be as durable as other options. 4. Clear Coating: Clear coating is a transparent protective layer that can be applied to aluminum profiles. It provides a glossy finish while preserving the natural appearance of the aluminum. Clear coating offers protection against corrosion, UV radiation, and other environmental factors. 5. Cladding: Cladding involves covering the aluminum profiles with another material, such as stainless steel or composite panels. This provides additional protection against corrosion and wear, while also adding aesthetic appeal and design versatility. 6. Film/Protective Tape: Applying a temporary film or protective tape to the surface of aluminum profiles can provide short-term protection during transportation, installation, or construction. These films or tapes can be easily removed after use, leaving the aluminum profile intact. Each of these surface protection options has its own advantages and disadvantages, and the choice depends on the specific requirements of the application, desired aesthetics, budget, and expected environmental conditions.

- Q: Are aluminum profiles suitable for earthquake-resistant structures?

- Yes, aluminum profiles can be suitable for earthquake-resistant structures. Aluminum is a lightweight and high-strength material that offers several advantages for earthquake resistance. Firstly, its high strength-to-weight ratio allows for the construction of lighter and more flexible structures, which can better withstand seismic forces. This characteristic is particularly important as it reduces the overall mass of the structure, minimizing the inertia forces during an earthquake. Furthermore, aluminum profiles have excellent corrosion resistance, ensuring the long-term durability and structural integrity of earthquake-resistant buildings. This is crucial as corrosion can weaken the structure over time, making it more vulnerable to seismic events. In addition, aluminum's malleability allows for the creation of complex and customized profiles, enabling architects and engineers to design structures that can effectively absorb and dissipate seismic energy. This flexibility is essential in earthquake-resistant design, as it allows the structure to deform and absorb the energy generated during an earthquake, reducing the impact on the building and its occupants. Moreover, aluminum is a sustainable material, as it is highly recyclable and requires significantly less energy to produce compared to other metals. This makes it an environmentally friendly choice for earthquake-resistant structures. However, it is worth noting that the suitability of aluminum profiles for earthquake-resistant structures also depends on various factors, such as the specific design requirements, local seismic conditions, and the expertise of the engineers and architects involved. Therefore, a thorough analysis and evaluation of the specific project requirements and conditions should be conducted before determining the suitability of aluminum profiles for earthquake-resistant structures.

- Q: This question asks for guidelines to ensure the proper and safe installation of aluminum profiles.

- <p>To ensure the correct and safe installation of aluminum profiles, follow these steps: 1. Use high-quality aluminum profiles that meet industry standards. 2. Prepare the surface by cleaning and leveling it. 3. Use appropriate tools like drills, screws, and cutting equipment. 4. Follow the manufacturer's guidelines for installation. 5. Ensure proper alignment and spacing of the profiles. 6. Secure the profiles with the right fasteners and adhesives. 7. Check for any sharp edges or protrusions after installation. 8. Regularly inspect and maintain the profiles to prevent any damage or wear. By adhering to these steps, you can ensure a safe and secure installation of aluminum profiles.</p>

- Q: Can aluminum profiles be used in corrosive environments?

- Before making a decision, it is important to take certain factors into consideration when using aluminum profiles in corrosive environments. Aluminum naturally resists corrosion due to the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing further corrosion. However, in highly corrosive environments such as areas with high humidity, exposure to saltwater, or acidic conditions, the protective oxide layer may degrade over time. To enhance the resistance of aluminum profiles in corrosive environments, several measures can be taken. One option is to select an aluminum alloy with higher corrosion resistance, such as marine-grade or corrosion-resistant alloys that contain a higher percentage of alloying elements like copper or zinc. Furthermore, surface treatments like anodizing or powder coating can further enhance the corrosion resistance of aluminum profiles. Anodizing involves the creation of a thicker and more durable oxide layer on the aluminum surface, while powder coating provides an additional protective layer that acts as a barrier against corrosive agents. Regular maintenance and cleaning are also crucial for preserving the corrosion resistance of aluminum profiles in corrosive environments. This includes the removal of any accumulated dirt or debris that may contain corrosive substances. In conclusion, while aluminum profiles can be used in corrosive environments, it is vital to choose the appropriate alloy, consider surface treatments, and perform regular maintenance to ensure their long-term performance and durability.

- Q: What are the potential environmental effects linked to the utilization of aluminum profiles?

- <p>Yes, there are environmental impacts associated with using aluminum profiles. The production process consumes significant energy, contributing to greenhouse gas emissions. Aluminum production also generates waste, including red mud, which can be harmful if not properly managed. However, aluminum is recyclable, and recycling reduces energy consumption and waste generation. The environmental impact can be mitigated by using recycled aluminum and adopting sustainable production practices.</p>

- Q: Are there any fire safety considerations when using aluminum profiles?

- Yes, there are fire safety considerations when using aluminum profiles. Although aluminum itself is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, especially when used in construction or industrial applications, can act as fuel for a fire and potentially increase its severity. One important consideration is the fire rating of the aluminum profiles. Fire ratings indicate the length of time a material can withstand exposure to fire before it fails. It is crucial to select aluminum profiles with appropriate fire ratings that align with the specific requirements of the application. This ensures that the profiles can delay the spread of fire, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of appropriate insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In such cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This helps prevent the fire from spreading through the building envelope and reduces the risk of structural failure. Additionally, fire safety measures should be implemented during the installation process. Proper firestopping techniques should be employed to seal any gaps or penetrations around the aluminum profiles. This helps prevent the passage of flames, smoke, and hot gases from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also essential for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, proper fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, while aluminum profiles themselves may not be combustible, it is important to consider various fire safety measures when using them in construction or industrial applications. By selecting appropriate fire-rated profiles, using fire-resistant insulation materials, implementing proper installation techniques, and maintaining regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight and durable material that is commonly used in various industries, including playground equipment manufacturing. It is known for its strength and resistance to corrosion, making it suitable for outdoor applications. Aluminum profiles provide structural stability and can withstand the weight and forces exerted during play. Additionally, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the playground equipment. The versatility of aluminum allows for the creation of various shapes and designs, providing endless possibilities for innovative and attractive playground structures. Overall, aluminum profiles are a suitable choice for playground equipment due to their strength, durability, and safety features.

Send your message to us

Customized Aluminum Extrusion Profiles - Aluminum 6063 T6 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords