Prime Quality Stainless Steel Sheets 201/304/316 Mirror Finish Stainless Steel Sheets

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

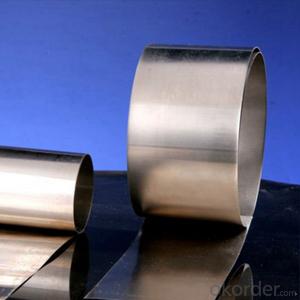

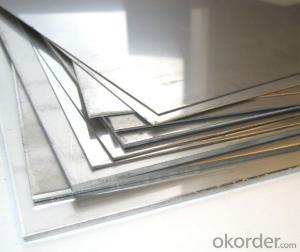

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What are the benefits of using textured stainless steel sheets?

- Textured stainless steel sheets have numerous advantages. Firstly, their unique patterns and textures enhance visual appeal and aesthetic value. These sheets can add depth and dimension to any space, making it visually interesting and appealing. As a result, they are highly sought after in architectural and interior design projects. Secondly, textured stainless steel sheets offer improved durability and resistance to wear and tear. Their textured surface helps conceal scratches, fingerprints, and other imperfections, ensuring a cleaner and more polished appearance for longer periods. This makes them ideal for high-traffic areas or applications where aesthetics and durability are equally important. Furthermore, these sheets provide better grip and traction due to the raised patterns on their surface. This makes them suitable for applications where slip resistance is crucial, such as flooring, stairs, or ramps. The enhanced grip also proves advantageous in industrial or commercial settings prioritizing safety. Moreover, textured stainless steel sheets require relatively low maintenance. Their textured surface is less prone to showing dirt or smudges, reducing the need for frequent cleaning or maintenance. This makes them convenient for applications in busy environments or areas where regular cleaning may be challenging. Lastly, textured stainless steel sheets are highly versatile and can be used in a wide range of applications. They find utility in architectural and interior design projects, as well as industrial and commercial settings. These sheets can be utilized for wall cladding, columns, decorative panels, countertops, furniture, and more, offering limitless possibilities for creative and functional design solutions. In conclusion, the benefits of using textured stainless steel sheets include enhanced visual appeal, improved durability, better grip and traction, low maintenance requirements, and versatility in application. These sheets offer a combination of practical and aesthetic advantages, making them a popular choice for various projects across different industries.

- Q: How do you clean and maintain stainless steel sheets?

- In order to clean and maintain stainless steel sheets, you will require a few basic supplies. These include a microfiber cloth or soft sponge, mild dish soap or a stainless steel cleaner, warm water, and a towel for drying. Begin by rinsing the stainless steel sheet with warm water to eliminate any loose dirt or grime. Next, gently scrub the surface of the stainless steel sheet using a small amount of mild dish soap applied to the microfiber cloth or sponge. It is important to avoid using abrasive materials or harsh chemicals as these can cause scratches or damage to the stainless steel. After cleaning, make sure to thoroughly rinse the sheet with warm water to remove any remaining soap residue. To prevent water spots, use a clean towel to dry the surface. Always remember to dry the stainless steel sheet after cleaning to prevent the formation of water spots or streaks. If there are stubborn stains or fingerprints that cannot be removed with soap and water, you can employ a stainless steel cleaner that is specifically designed for this purpose. Follow the instructions provided with the cleaner and use a soft cloth to apply it to the sheet. To avoid scratching the surface, wipe in the direction of the grain. Rinse thoroughly and dry as mentioned earlier. To maintain the shine and luster of stainless steel sheets, it is important to refrain from using abrasive cleaners, scouring pads, or steel wool as these can harm the surface. Additionally, avoid using cleaners that contain bleach or chlorine as they can cause discoloration. Regularly cleaning the stainless steel sheets is crucial to prevent the buildup of dirt, grease, or other contaminants that can result in corrosion. For most applications, a weekly cleaning routine should be sufficient, although in high-traffic or heavily used areas, more frequent cleaning may be necessary. In conclusion, the process of cleaning and maintaining stainless steel sheets involves gently scrubbing with mild dish soap or a stainless steel cleaner, rinsing with warm water, and ensuring thorough drying. By following these steps and avoiding abrasive materials, your stainless steel sheets will remain clean, shiny, and in optimal condition for years to come.

- Q: Are stainless steel sheets good for cryogenic storage?

- Stainless steel sheets are widely utilized in cryogenic storage owing to their exceptional characteristics. Renowned for its remarkable strength, durability, and corrosion resistance, stainless steel proves to be ideal for extreme temperature settings such as cryogenic storage. Furthermore, stainless steel retains its mechanical properties even under extremely low temperatures, guaranteeing the safety and integrity of stored materials. Moreover, stainless steel sheets exhibit favorable thermal conductivity, enabling efficient heat transfer throughout cryogenic processes. As a result, stainless steel sheets emerge as a dependable option for cryogenic storage purposes.

- Q: What are the standard sizes of stainless steel sheets?

- The specific industry and application dictate the varying standard sizes of stainless steel sheets. Nevertheless, there exist some widely accessible commonly used standard sizes. In the architectural and construction sector, stainless steel sheets usually come in sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to 5 feet by 10 feet (1524mm x 3048mm). These dimensions find common use in cladding, roofing, and interior design applications. In the manufacturing and industrial domains, stainless steel sheets are available in diverse sizes, including 4 feet by 8 feet, 4 feet by 10 feet (1220mm x 3050mm), and even larger sizes like 5 feet by 12 feet (1524mm x 3658mm). These larger dimensions frequently serve fabrication, industrial machinery, and equipment manufacturing purposes. It is important to acknowledge that custom sizes can also be produced according to specific project requirements. These custom sizes may encompass narrower or wider widths, longer or shorter lengths, or even different thicknesses to cater to a particular application's needs. Ultimately, industry standards, market demand, and manufacturer capabilities determine the standard sizes of stainless steel sheets. It is advisable to consult suppliers or manufacturers to verify the availability of the desired size before making a purchase.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Yes, stainless steel sheets are suitable for chemical transport containers. Stainless steel is known for its excellent corrosion resistance, which makes it highly suitable for transporting chemicals. It is resistant to many acids, alkalis, and corrosive substances, ensuring that the chemicals being transported are not compromised or contaminated during transit. Additionally, stainless steel sheets are also durable and strong, providing structural integrity to the containers and ensuring the safe transportation of chemicals.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are suitable for chemical storage tanks. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for storing various chemicals. It is resistant to many corrosive substances, including acids, alkalis, and solvents, which are commonly stored in chemical storage tanks. Stainless steel sheets also have a high strength-to-weight ratio, allowing for the construction of tanks that can withstand the pressure and weight of the chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storing chemicals. Overall, stainless steel sheets are a reliable and suitable material for chemical storage tanks.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To effectively eliminate adhesive residue from stainless steel sheets, the following steps can be followed: 1. Commence by delicately scraping off as much of the residue as possible using a plastic scraper or your fingernail. Exercise caution to avoid scratching the stainless steel surface. 2. Subsequently, moisten a soft cloth with warm water and a mild detergent or dish soap. Employ gentle circular motions to scrub the adhesive residue. Refrain from using abrasive cleaners or scrub brushes as they have the potential to harm the stainless steel finish. 3. If the adhesive residue persists, consider utilizing a non-abrasive cleaner specifically designed for stainless steel. Apply a small quantity of the cleaner to a soft cloth and gently rub the residue until it detaches. 4. In the case of tenacious adhesive residue, a paste can be concocted by combining baking soda and water. Apply the paste to the affected area and allow it to sit for a few minutes. Subsequently, utilize a soft cloth to gently scrub the residue in circular motions. 5. Thoroughly rinse the stainless steel sheet with warm water to eliminate any remaining residue or cleaner. 6. Finally, employ a clean, soft cloth to dry the surface, thereby preventing water spots and streaks. It is important to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet prior to applying it to the entire surface. This precautionary measure ensures that no damage or discoloration occurs.

- Q: How do you install stainless steel sheets?

- In order to install stainless steel sheets, there are a few basic tools you will need and some steps that should be followed: 1. Begin by measuring and preparing the area where you intend to install the stainless steel sheets. Ensure that the surface is clean, dry, and free from any dust or debris. If necessary, smooth out any rough spots or imperfections on the surface by sanding them down. 2. Cut the sheets to the desired size and shape using a metal cutting tool such as a circular saw or a jigsaw with a metal cutting blade. For your safety, remember to wear protective goggles and gloves while cutting. 3. Apply a high-strength construction adhesive to the backside of the stainless steel sheet. Ensure that the adhesive is applied evenly, without leaving any gaps or air pockets. To achieve better coverage, you may use a notched trowel to spread the adhesive. 4. Carefully position the stainless steel sheet onto the prepared surface, making sure it is properly aligned. Apply gentle and consistent pressure to ensure that the sheet adheres to the surface. A roller or clean cloth can be used to firmly press the sheet onto the surface. 5. If necessary, use stainless steel screws to further secure the sheet. Place the screws evenly along the edges and corners, ensuring proper spacing. Be cautious not to overtighten the screws in order to avoid damaging the sheet. 6. Trim any excess stainless steel sheet that hangs over the edges to achieve the desired size. Use a metal cutting tool for this task. Once trimmed, smooth out any rough edges with a file or sandpaper. To give the sheet a polished finish and remove any smudges or fingerprints, a stainless steel cleaner can be used. Always make sure to follow the manufacturer's instructions for the specific stainless steel sheets you are using, as installation methods may slightly vary. If you are unsure or uncomfortable with the installation process, it is recommended to seek professional assistance.

- Q: How are stainless steel sheets made?

- Stainless steel sheets are made through a process called cold rolling, where stainless steel ingots are passed through a series of rollers to reduce their thickness. This is followed by annealing, where the sheets are heated to remove any stress and improve their mechanical properties. Finally, they undergo finishing processes like pickling and polishing to achieve the desired surface finish.

- Q: What are the different types of perforations available for stainless steel sheets?

- Stainless steel sheets offer several options for perforations, each with its own purpose and characteristics. Here are some of the most common types available: 1. Round Perforations: The most widely used type, these consist of evenly spaced round holes punched through the sheet. They provide good airflow, visibility, strength, and durability. 2. Square Perforations: Similar to round perforations, square ones have evenly spaced square holes. They are preferred for a more modern and geometric aesthetic, creating visually appealing patterns. 3. Slotted Perforations: These have elongated, rectangular holes for better drainage and airflow. They are ideal for grilles, screens, and filters. 4. Hexagonal Perforations: Featuring hexagon-shaped holes, this type offers an interesting visual pattern and increased strength and rigidity. 5. Decorative Perforations: Designed to enhance the aesthetic appeal, these come in various shapes, sizes, and patterns such as floral or custom designs. They are commonly used in architecture, interior design, and decorative panels. 6. Micro Perforations: These are extremely small and closely spaced holes for applications requiring high precision and fine filtering, like speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

Send your message to us

Prime Quality Stainless Steel Sheets 201/304/316 Mirror Finish Stainless Steel Sheets

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords