Stainless Steel Sheets Decorative 201 Colored Black Stainless Steel Sheet in Good Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

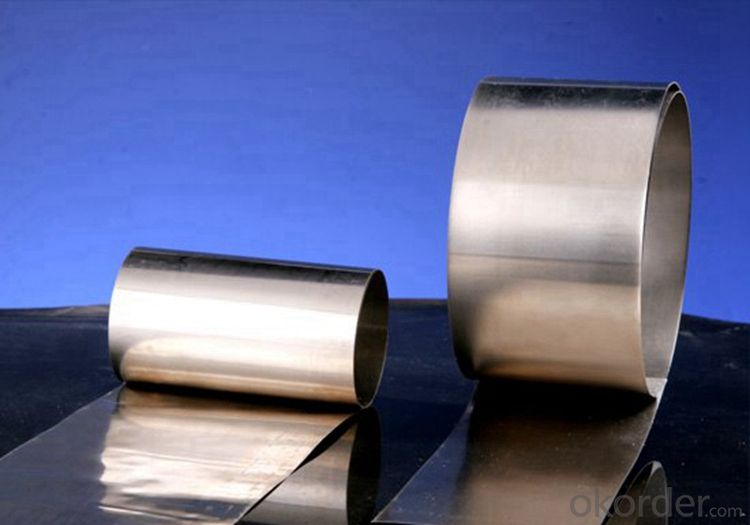

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Are stainless steel sheets suitable for architectural louvers or screens?

- Yes, stainless steel sheets are suitable for architectural louvers or screens. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for outdoor applications such as louvers or screens. It can withstand harsh weather conditions, including rain, UV exposure, and temperature fluctuations, without losing its structural integrity or aesthetic appeal. Stainless steel also offers a sleek and modern appearance, which enhances the overall design of architectural louvers or screens. Additionally, stainless steel sheets can be easily customized to create various patterns, shapes, and sizes, allowing for flexibility in design and functionality. Overall, stainless steel sheets are a reliable and long-lasting choice for architectural louvers or screens.

- Q: What are the different types of stainless steel sheet coatings available?

- There are several different types of stainless steel sheet coatings available, each offering unique properties and benefits. Some of the most common types include: 1. Galvanized Coatings: These coatings are made by applying a layer of zinc to the surface of the stainless steel sheet. This helps to protect the steel from corrosion and rusting. Galvanized coatings are commonly used in outdoor applications or in environments where the steel is exposed to moisture or chemicals. 2. Powder Coatings: Powder coatings are a popular choice for stainless steel sheets as they provide excellent durability and resistance to corrosion. This type of coating is applied as a dry powder and then heated to form a hard protective layer. Powder coatings come in a variety of colors and finishes, allowing for customization and aesthetic appeal. 3. Electroplating: Electroplating involves the deposition of a thin layer of another metal onto the stainless steel sheet. Common metals used for electroplating include chrome, nickel, and zinc. This coating not only enhances the appearance of the steel but also improves its resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings involve the deposition of a thin film onto the stainless steel sheet using a vacuum process. These coatings can provide various properties such as improved hardness, scratch resistance, and color options. PVD coatings are commonly used in architectural applications or for decorative purposes. 5. Organic Coatings: Organic coatings, such as paints or lacquers, can also be applied to stainless steel sheets. These coatings provide an additional layer of protection against corrosion, as well as offering aesthetic options. Organic coatings are often used in applications where color matching or branding is important. Each type of stainless steel sheet coating has its advantages and is suitable for specific applications. The choice of coating will depend on factors such as the intended use, desired appearance, and environmental conditions in which the stainless steel will be exposed. It is important to carefully consider these factors and consult with experts to choose the most suitable coating for your specific needs.

- Q: Can stainless steel sheets be used for conveyor belts?

- Certainly! Conveyor belts can utilize stainless steel sheets. Stainless steel, being highly durable and resistant to corrosion, is well-suited for diverse industrial uses, such as conveyor belts. These sheets possess the capability to endure high temperatures, heavy loads, and abrasive substances, making them perfect for conveying purposes. Moreover, the smooth surface of stainless steel facilitates the smooth movement of products and reduces friction, ensuring efficient and dependable conveyor operations.

- Q: How do you prevent fingerprints on stainless steel sheets?

- To prevent fingerprints on stainless steel sheets, you can wipe them down with a clean microfiber cloth or use a stainless steel cleaner specifically designed to repel fingerprints. Additionally, handling the sheets with clean, dry hands and avoiding touching them unnecessarily can help minimize fingerprint smudges.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: What are the benefits of using embossed stainless steel sheets in elevator doors?

- Embossed stainless steel sheets offer several benefits for elevator doors. Firstly, the embossed pattern adds a touch of elegance and sophistication, enhancing the overall aesthetic appeal of the elevator. Additionally, the embossed texture helps to improve grip and prevent slipping, ensuring safety for passengers. Furthermore, stainless steel is highly durable and resistant to corrosion, making it an ideal material for elevator doors that are subject to constant use and exposure to various environmental factors. Lastly, stainless steel sheets are easy to clean and maintain, saving time and effort in the long run.

- Q: What is the density of stainless steel sheets?

- The density of stainless steel sheets may differ based on the particular grade and thickness of the sheet. Nevertheless, stainless steel sheets generally possess a density of approximately 8,000 kilograms per cubic meter (kg/m³) or 8 grams per cubic centimeter (g/cm³). This elevated density is among the factors contributing to stainless steel's reputation for strength and durability.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are several different types of stainless steel sheet embossing patterns available. Some of the most common patterns include: 1. Diamond: This pattern features a series of diamond-shaped indentations evenly spaced across the surface of the sheet. It creates a visually appealing and textured appearance. 2. Linen: The linen pattern resembles the texture of linen fabric, with a series of parallel lines running in one direction and perpendicular lines intersecting them. It adds a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the surface of the sheet. It is commonly used in architectural applications to add visual interest and a tactile feel. 4. Leather: This pattern replicates the texture of leather, with a series of irregular lines and indentations. It provides a unique and luxurious appearance to stainless steel sheets. 5. Hammered: The hammered pattern features a series of irregular indentations that resemble the marks made by a hammer. It adds a rustic and handcrafted look to stainless steel sheets. 6. Checkerboard: This pattern consists of a grid of squares, with alternating squares raised or recessed. It creates a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern features a series of curved lines that resemble ocean waves. It adds a dynamic and flowing look to stainless steel sheets. These are just a few examples of the many different types of stainless steel sheet embossing patterns available. Each pattern can be customized in terms of size, depth, and spacing to suit specific design preferences and applications.

- Q: Can stainless steel sheets be used for elevator cladding?

- Yes, stainless steel sheets can be used for elevator cladding. Stainless steel is a popular choice for elevator cladding due to its durability, aesthetic appeal, and resistance to corrosion and staining. It provides a sleek and modern look while also offering protection against wear and tear in high-traffic areas.

- Q: What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

Send your message to us

Stainless Steel Sheets Decorative 201 Colored Black Stainless Steel Sheet in Good Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords