Grade 304 No.8 Finish Stainless Steel Sheet price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

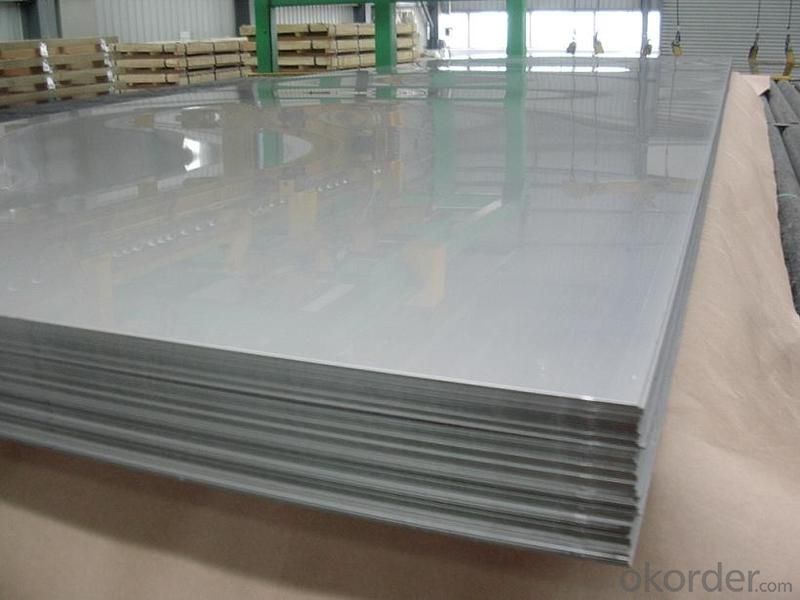

Grade 304 No.8 Finish Stainless Steel Sheet price

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

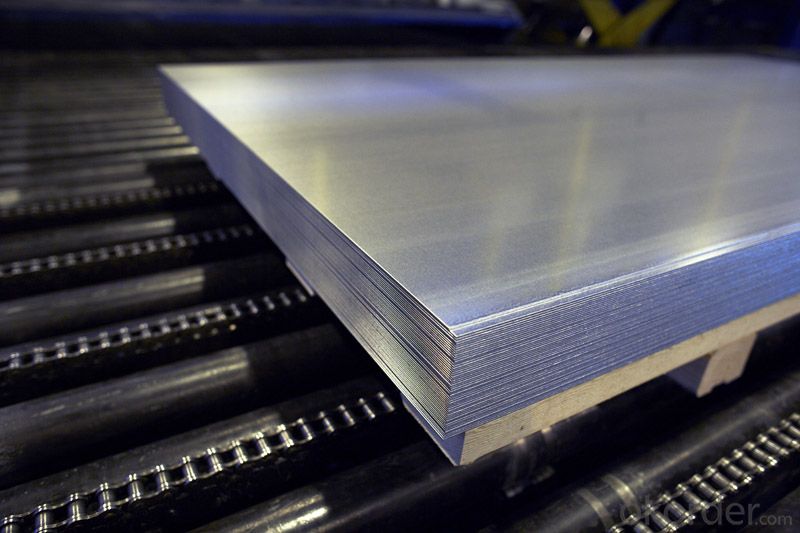

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What are the pricing options for stainless steel sheets?

- The pricing of stainless steel sheets can vary depending on a range of factors. First and foremost, the grade of stainless steel used plays a significant role. Stainless steel is available in various grades, each offering different levels of corrosion resistance and durability. Higher-grade stainless steel sheets generally come at a higher price. Another factor that influences pricing is the thickness and size of the sheets. Thicker and larger stainless steel sheets tend to be more expensive due to the increased amount of raw material required and the additional processing involved. Moreover, the finish of the stainless steel sheets can also impact the pricing. Different finishes, such as brushed, mirror, or matte, are available for stainless steel sheets. Finishes that necessitate more extensive processing and polishing may come at a higher cost. Additionally, market conditions, including the supply and demand for stainless steel, can affect pricing. Prices can fluctuate based on factors such as raw material costs, production capacity, and global economic conditions. Furthermore, it is crucial to consider the supplier or manufacturer from whom you are purchasing the stainless steel sheets. Different suppliers may offer varying pricing options based on their overhead costs, production capabilities, and market positioning. To summarize, the pricing options for stainless steel sheets are influenced by factors such as grade, thickness, size, finish, market conditions, and the supplier. It is advisable to conduct thorough research and compare prices from different sources to find the most suitable option for your specific requirements.

- Q: Can stainless steel sheets be used for solar water heaters?

- Yes, stainless steel sheets can be used for solar water heaters. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of solar water heating systems. It ensures longevity and reliable performance in capturing and transferring solar energy to heat water efficiently.

- Q: Can stainless steel sheets be used for hygienic environments?

- Stainless steel sheets are indeed suitable for hygienic environments. This is because stainless steel possesses certain inherent properties that render it highly resistant to corrosion, heat, and chemical damage, thus making it a popular choice for such environments. Its surface is smooth and non-porous, which facilitates easy cleaning and prevents the accumulation of bacteria, mold, or other contaminants. Furthermore, stainless steel is non-reactive and does not release any harmful substances, making it ideal for sensitive environments like food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Moreover, stainless steel is both durable and long-lasting, ensuring excellent hygiene and cleanliness for extended periods. All in all, stainless steel sheets are a dependable and hygienic option for various applications in environments that prioritize cleanliness and sanitation.

- Q: What's the difference between the 304 stainless steel plate and the 310S stainless steel plate?

- The common marking methods in the field are 0Cr18Ni9, SUS304, in which 06Cr19Ni10 generally means GB standard production, S30408 generally represents ASTM standard production, and SUS 304 represents daily standard production.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is widely used in the pharmaceutical industry due to its excellent resistance to corrosion, durability, and ease of cleaning. It is a non-porous material that does not harbor bacteria or contaminants, making it ideal for cleanroom environments where maintaining a sterile and hygienic environment is crucial. Stainless steel sheets are also easy to sanitize and withstand harsh cleaning agents without deteriorating or releasing particles that could contaminate the pharmaceutical products being manufactured. Additionally, stainless steel has a smooth and non-shedding surface, which prevents the accumulation of particles and facilitates cleanroom maintenance. Overall, stainless steel sheets are an excellent choice for pharmaceutical cleanrooms to ensure compliance with strict cleanliness and sterility requirements.

- Q: Can stainless steel sheets be used in food processing or medical applications?

- Yes, stainless steel sheets can be used in food processing and medical applications. Stainless steel is highly resistant to corrosion and is easy to clean, making it suitable for use in environments that require strict hygiene standards such as food processing plants and medical facilities. It is also non-reactive with food and medical substances, ensuring the safety and quality of the products being processed or treated.

- Q: Can stainless steel sheets be used for elevator flooring?

- Stainless steel sheets are indeed suitable for elevator flooring. The reason behind their popularity lies in their exceptional durability, strength, and corrosion resistance. These sheets can effortlessly withstand substantial foot traffic while ensuring effortless cleaning and maintenance. Moreover, stainless steel possesses an aesthetic charm that lends elevators a sleek and contemporary appearance.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Indeed, stainless steel sheets prove to be apt for cryogenic applications. Renowned for its commendable mechanical attributes like remarkable strength and resilience, stainless steel emerges as an ideal choice for environments characterized by low temperatures. Furthermore, stainless steel exhibits an impressive ability to resist corrosion, a critical quality when confronted with cryogenic temperatures. It remains steadfast in maintaining its mechanical properties, steadfastly refusing to succumb to brittleness even in ultra-low temperatures. Consequently, stainless steel sheets find themselves widely employed in cryogenic applications such as storage tanks, pipelines, and equipment designed to handle liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q: Are stainless steel sheets resistant to crevice corrosion?

- Yes, stainless steel sheets are generally resistant to crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface and prevents the formation of crevices where corrosion can occur.

- Q: What is the abrasion resistance of stainless steel sheets?

- Stainless steel sheets are widely acknowledged for their high level of abrasion resistance. They possess exceptional durability and hardness, which render them impervious to damage caused by friction or contact with abrasive substances. The extent of this abrasion resistance can differ, depending on factors such as the grade and finish of the stainless steel sheet, as well as the particular purpose it serves. Nonetheless, stainless steel sheets are renowned for their outstanding ability to withstand scratches, scuffs, and other types of abrasion, thereby making them a preferred option across diverse industries that prioritize longevity and durability.

Send your message to us

Grade 304 No.8 Finish Stainless Steel Sheet price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords