TISCO stainless steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel sheet

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steelcoil and stainless steel tube.

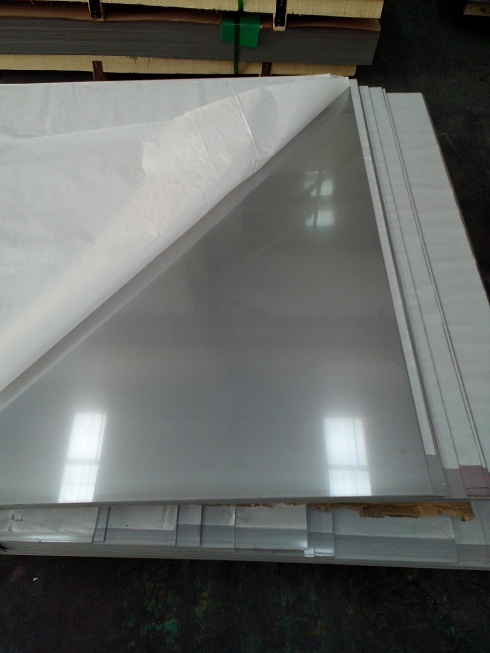

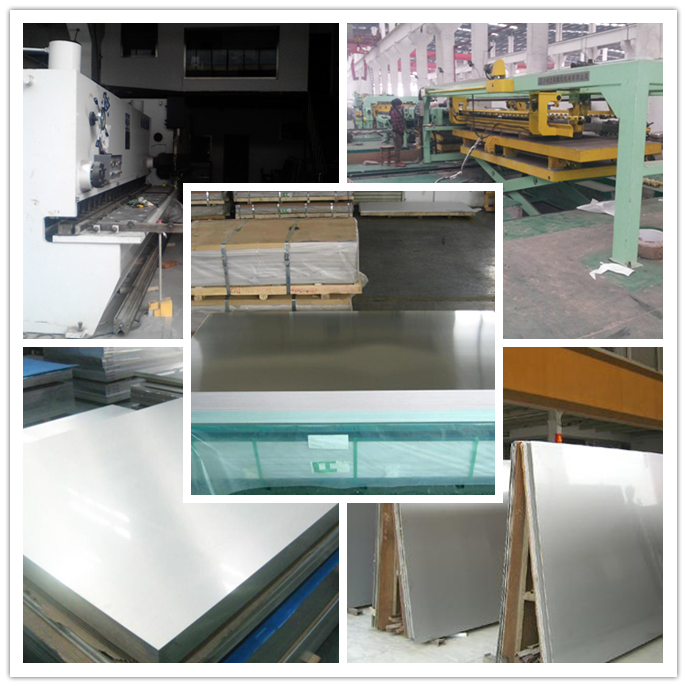

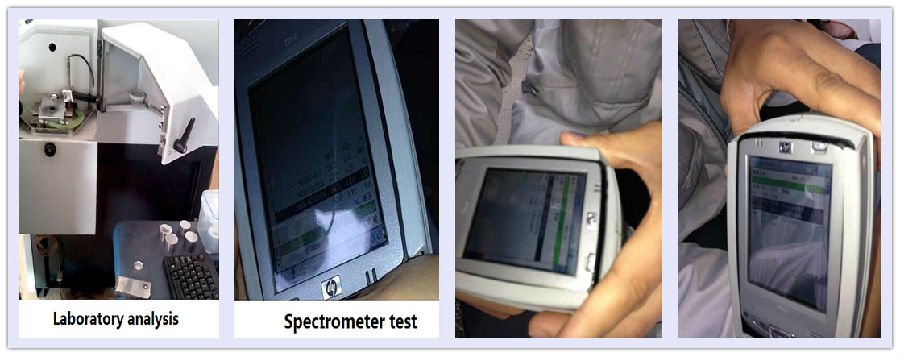

A series of pictures

stainless steel sheet

1.Surface:2B/BA/4K/6K/8K

2.Thickness:0.3-3mm

3.Width:1m 1.219m 1.5m

4.Length:1.5m 6m or as your requirement

A series of picturs

A series of pictures

A series of pictures

A series of pictures

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, making it an excellent choice for environments with high moisture and chemical exposure, such as wastewater treatment plants. It can withstand the harsh conditions and provide long-lasting durability. Additionally, stainless steel is easy to clean and maintain, which is essential in a wastewater treatment facility where cleanliness and hygiene are critical. The material also has a high strength-to-weight ratio, making it suitable for various applications within the plant, such as tanks, piping, and equipment. Overall, stainless steel sheets are a reliable and practical choice for wastewater treatment plants.

- Q: Can stainless steel sheets be used for conveyor belts?

- Yes, stainless steel sheets can be effectively used for conveyor belts. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an ideal material for conveyor belts in various industries such as food processing, pharmaceuticals, and automotive. Its smooth surface also allows for easy cleaning and maintenance, ensuring hygiene and efficiency in conveyor operations.

- Q: Are stainless steel sheets resistant to chemicals and acids?

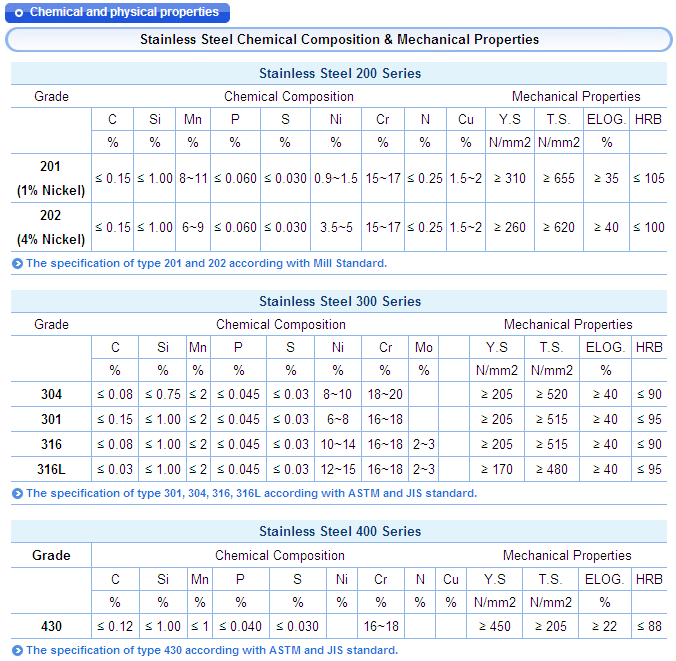

- Stainless steel sheets possess resistance against chemicals and acids, thanks to the high percentage of chromium they contain. This results in the formation of a protective layer on the metal's surface, granting it exceptional resistance to corrosion and damage caused by chemicals and acids. Moreover, the inclusion of elements like nickel and molybdenum further enhances this corrosion-resistant quality. Industries like chemical processing, pharmaceuticals, food and beverage, and automotive widely employ stainless steel sheets due to their exposure to aggressive chemicals and acids. The reliability and durability of stainless steel in withstanding corrosion and chemical attack render it an ideal material for applications requiring such resistance.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat pieces of metal made from stainless steel, a type of alloy that contains chromium, nickel, and other elements. These sheets are highly versatile and widely used in various industries for their excellent corrosion resistance, durability, and aesthetic appeal. They are manufactured through a process called hot rolling or cold rolling, which involves passing the steel through a series of rollers to achieve the desired thickness and finish. Stainless steel sheets are commonly used for applications such as construction, automotive manufacturing, kitchenware, appliances, and architecture. They come in different grades, surface finishes, and sizes to cater to different requirements. Whether it's for decorative purposes or functional applications, stainless steel sheets offer a reliable and long-lasting solution.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Stainless steel sheets are highly resistant to various types of corrosion, including general corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking.

- Q: How are stainless steel sheets finished?

- Stainless steel sheets can be finished in various ways to achieve different appearances and textures. The most common finishing techniques for stainless steel sheets include: 1. Mill Finish: This is the standard finish when stainless steel sheets are initially produced. It has a dull, non-reflective surface with visible grain lines caused by the manufacturing process. 2. Brushed Finish: Also known as satin finish, this technique involves brushing the stainless steel surface with an abrasive material to create a consistent, fine grain appearance. It provides a smooth and matte finish, which is often preferred for aesthetic purposes. 3. Mirror Finish: As the name suggests, this finish creates a highly reflective and mirror-like surface on stainless steel sheets. It is achieved by polishing the surface with progressively finer grits of abrasive materials until a smooth and reflective finish is obtained. 4. Embossed Finish: This finish involves impressing a pattern or design onto the stainless steel sheet surface. Embossing can be done using heat and pressure to create raised or recessed patterns, adding texture and visual interest to the sheet. 5. Bead Blasted Finish: This technique uses fine glass beads or other abrasive materials to blast the stainless steel surface. It creates a uniform, matte appearance with a slightly textured finish. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or alloy is vaporized and deposited onto the stainless steel sheet surface. This coating enhances the appearance of the sheet, providing various colors and finishes such as gold, bronze, or black. Overall, choosing the appropriate finish for stainless steel sheets depends on the desired aesthetic, functionality, and application of the material. Each finish has its unique characteristics, allowing for versatility and customization in different industries, including architecture, interior design, automotive, and many others.

- Q: Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a popular choice for elevator doors due to its durability, corrosion resistance, and aesthetic appeal. Elevator doors are subject to constant use and exposure to various elements, making stainless steel an ideal material as it does not rust or corrode easily. Additionally, stainless steel sheets can be easily maintained and cleaned, ensuring a long-lasting and visually pleasing appearance. The versatility of stainless steel also allows for customization in terms of finishes, textures, and patterns, allowing elevator doors to be designed to match the desired aesthetic of the building or space. Overall, stainless steel sheets are a reliable and suitable choice for elevator doors.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The strain hardening exponent of stainless steel sheets typically ranges from 0.2 to 0.4, depending on the specific grade and manufacturing process.

- Q: What are the different types of edge finishes for stainless steel sheets?

- There are several different types of edge finishes that can be applied to stainless steel sheets. These finishes are designed to enhance the appearance and functionality of the edges while also providing protection against corrosion and damage. 1. Mill Finish: This is the most basic type of edge finish, where the edges are left as they come from the mill. It is a straight, unfinished edge without any additional treatment or polishing. 2. Deburred Edge: In this type of finish, the rough edges are smoothed out and deburred using abrasive materials. This helps to eliminate sharp edges and burrs, making the sheet safer to handle and preventing potential injuries. 3. Rounded Edge: A rounded edge finish involves milling or machining the edges to create a curved or rounded profile. This type of finish is commonly used in applications where safety is a concern, as it reduces the risk of cuts or injuries caused by sharp edges. 4. Beveled Edge: A beveled edge finish involves cutting or grinding the edges at an angle to create a sloped or chamfered profile. This type of finish is often used for aesthetic purposes, as it adds a decorative element to the sheet and can create a smooth transition between different surfaces. 5. Polished Edge: In this type of finish, the edges of the stainless steel sheet are polished to a high shine using abrasive materials or polishing compounds. This produces a smooth, reflective surface that enhances the overall appearance of the sheet and gives it a more finished look. 6. Brushed Edge: A brushed edge finish involves applying a brushed texture to the edges of the stainless steel sheet. This is achieved by using abrasive materials or brushes to create a consistent pattern of fine lines or scratches. The brushed edge finish can provide a unique and contemporary look to the sheet. These different types of edge finishes for stainless steel sheets offer various benefits and can be chosen based on the specific requirements of the application. Whether it's for safety, aesthetics, or functionality, selecting the right edge finish can greatly enhance the performance and visual appeal of stainless steel sheets.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can mix equal parts vinegar and water in a spray bottle and spray the affected areas. Let it sit for a few minutes, then wipe it off with a soft cloth. Additionally, you can use a stainless steel cleaner or polish specifically designed for removing water spots.

Send your message to us

TISCO stainless steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords