Stainless Steel Sheets 201/310s/304/304L/309S/316l/316/430 Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

ITEM | DESCRIPTION |

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system |

Process | Hot rolled / cold rolled |

Payment | L/C,T/T |

MOQ | 20 Ton |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

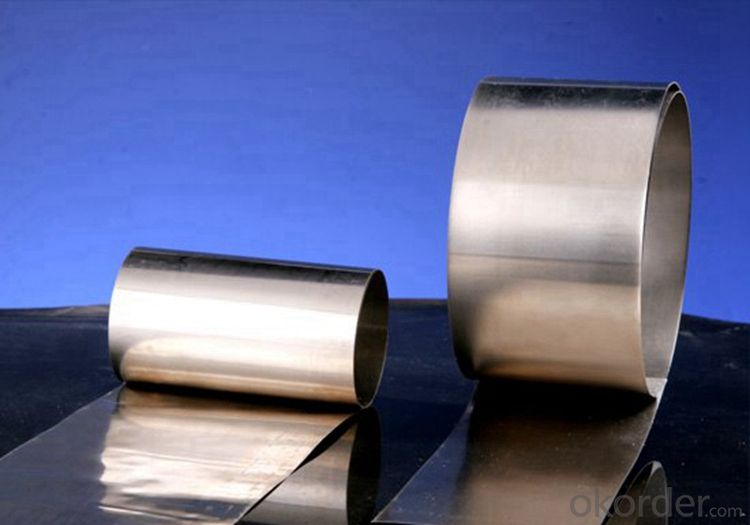

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: How do you calculate the cost of a stainless steel sheet?

- Calculating the cost of a stainless steel sheet involves taking into account several factors. To begin, it is necessary to determine the dimensions of the sheet, including its length, width, and thickness. These measurements will dictate the amount of material required, which is a crucial aspect in determining the cost. Another factor to consider is the grade of the stainless steel sheet. Different grades, such as 304, 316, or 430, possess distinct properties and are associated with varying costs. The specific grade necessary for a particular application will influence the sheet's price. The finish of the stainless steel sheet is also important to consider. Options like brushed, polished, or patterned finishes all entail different processes and materials, which in turn impacts the cost. Additionally, the quantity of stainless steel sheets needed can affect the overall cost. Bulk orders are often eligible for discounted prices, while smaller quantities may incur higher expenses. Conducting thorough research on different suppliers is crucial. Prices can fluctuate depending on factors such as the supplier's location, reputation, and prevailing market conditions. Comparing prices among various suppliers is essential to obtain the most favorable cost. It is worth noting that there may be additional costs involved, such as transportation fees, handling charges, or cutting fees. It is advisable to inquire about these potential expenses when requesting quotes from suppliers. By taking these factors into consideration and conducting comprehensive research, it is possible to accurately calculate the cost of a stainless steel sheet.

- Q: Can stainless steel sheets be used for electrical conductivity?

- Yes, stainless steel sheets can be used for electrical conductivity as they have relatively low electrical resistance and are often used in applications where electrical current needs to flow efficiently.

- Q: Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets are commonly used for brewery tanks. Stainless steel is a preferred material in the brewing industry due to its corrosion resistance, durability, and ease of cleaning. It is an ideal choice for tanks that require high sanitary standards and frequently come in contact with acidic or caustic substances.

- Q: Are stainless steel sheets suitable for dairy processing equipment?

- Stainless steel sheets prove to be a highly suitable option for dairy processing equipment. The dairy industry extensively employs stainless steel owing to its impressive resistance to corrosion, hygienic properties, and ease of cleaning. The sleek and non-porous surface of stainless steel effectively hinders the proliferation of bacteria and other microorganisms, thereby making it a perfect choice for upholding the cleanliness and safety standards of dairy processing equipment. Furthermore, stainless steel showcases resistance to chemical reactions with dairy products, ensuring the integrity and quality of processed milk and other dairy items. Additionally, stainless steel sheets exhibit durability and can endure high temperatures and frequent cleaning, rendering them an exceptional selection for dairy processing equipment that necessitates regular sanitization and sterilization.

- Q: What type of stainless steel plate made by imported vibrating disk?

- Jing Xin sharp vibration disk equipment is still very good, is a good choice. Kunshan Jing Xin Rui vibration disk equipment factory is a professional manufacturer of non-standard vibrating disk enterprises. Main vibrating disk, linear vibrator, control box and so on, the products are widely used in light industry, machinery, electronics, electrical appliances, hardware, plastics, toys, medicine, food and other industries.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a process called hot rolling, where stainless steel ingots are heated and passed through a series of rollers to reduce their thickness and improve their surface finish. This continuous rolling process creates long sheets of stainless steel, which are then cooled and cut into desired lengths. The sheets may undergo further processing, such as annealing or surface treatment, before being packaged and shipped for various applications.

- Q: What are the different types of stainless steel sheet finishes for food processing applications?

- Various types of stainless steel sheet finishes are commonly used in food processing applications. 1. Achieved through hot rolling, the No. 1 Finish leaves the stainless steel sheet with a rough surface. Due to its lack of smoothness, it is not typically used in food processing applications as it can harbor bacteria. 2. The No. 2B Finish, on the other hand, is a smooth and reflective finish achieved through cold rolling and annealing of the stainless steel sheet. This finish is commonly used in food processing applications as it is easy to clean and maintain. 3. If a brushed appearance is desired, the No. 4 Finish is achieved by creating a uniform grain on the surface using abrasive materials. This finish is often used in food processing applications where a decorative or aesthetic finish is desired. 4. For the most reflective finish available, the No. 8 Mirror Finish is achieved by polishing the surface until it becomes highly reflective and mirror-like. This finish is often used in food processing applications that require a high level of cleanliness and hygiene. Aside from these finishes, there are also specialized finishes such as bead blasted, patterned, and embossed finishes that can be used in food processing applications to meet specific aesthetic or functional requirements. Ultimately, the choice of finish will depend on the specific needs of the food processing application, including factors such as hygiene, ease of cleaning, and aesthetic considerations.

- Q: How do you polish stainless steel sheets?

- Achieving a polished look for stainless steel sheets can be accomplished by following a few straightforward steps. Begin by ensuring that the surface is immaculate and devoid of any dirt or debris. To eliminate any stains or marks, a mild detergent or stainless steel cleaner can be used. Next, utilize a soft cloth or sponge to apply either a stainless steel polish or a mixture of vinegar and olive oil. Apply the polish in the direction of the grain, which typically appears as a linear pattern on the stainless steel surface. Once the polish has been applied, utilize another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to exhibit a shining, polished appearance. If necessary, repeat the process in areas that require further polishing, ensuring that all excess polish is wiped away to prevent streaks or residue. It is crucial to consider that different stainless steel finishes may necessitate specific polishing techniques or products. For optimal results, always consult the manufacturer's instructions or guidelines.

- Q: How are stainless steel sheets made?

- Stainless steel sheets undergo a process called hot rolling to be produced. This starts by melting iron, nickel, chromium, and other elements in an electric arc furnace. The resulting mixture is then cast into large rectangular blocks known as slabs. The slabs are subjected to high temperatures and passed through a series of hot rolling mills. These mills consist of large rollers that gradually decrease the slab's thickness while increasing its length and width. As the slab goes through each rolling mill, it is constantly squeezed by the rollers, resulting in a thinner and longer sheet. Following the hot rolling process, the stainless steel sheet goes through annealing. This involves heating the sheet to a specific temperature and then allowing it to cool slowly. This process helps release internal stresses and enhance the material's mechanical properties. Next comes pickling, where the sheet is submerged in an acid solution to eliminate any surface impurities and oxides. This improves the appearance and corrosion resistance of the stainless steel. Once the pickling process is done, the sheet undergoes cold rolling. Cold rolling further decreases the sheet's thickness and improves its surface finish. This is done at room temperature, increasing the hardness and strength of the stainless steel. Lastly, the stainless steel sheet undergoes various finishing processes. These may include cutting to size, leveling, surface polishing, and coating to enhance appearance or protect against corrosion. In conclusion, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, annealing, pickling, cold rolling, and finishing processes. This ensures that the final product meets the desired specifications in terms of thickness, strength, and surface finish.

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, each designed to serve specific purposes and meet different aesthetic preferences. Some of the commonly used patterns include: 1. Round Hole Pattern: This is the most basic and widely used perforated pattern. It consists of evenly spaced round holes across the sheet, allowing for excellent airflow and drainage. It is commonly used in industrial applications such as filtration systems or as decorative panels. 2. Square Hole Pattern: Similar to the round hole pattern, the square hole pattern offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, as it provides a modern and sleek look. 3. Slotted Hole Pattern: Slotted holes are elongated and rectangular in shape, providing more flexibility in terms of airflow and visibility. They are often used in applications that require better drainage or where a higher open area is needed, such as in grills or air ventilation systems. 4. Hexagonal Hole Pattern: Hexagonal holes offer a unique and visually appealing pattern. They provide excellent strength and structural integrity, making them suitable for applications that require durability, such as safety barriers or machine guards. 5. Decorative Hole Pattern: Apart from the standard perforated patterns, there are also various decorative hole patterns available for stainless steel sheets. These patterns usually feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. It is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal, when selecting the appropriate perforated pattern for stainless steel sheets. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

Send your message to us

Stainless Steel Sheets 201/310s/304/304L/309S/316l/316/430 Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords