Prime Quality Stainless Steel 201 Grade Stainless Steel Sheets For Construction Building Metals

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

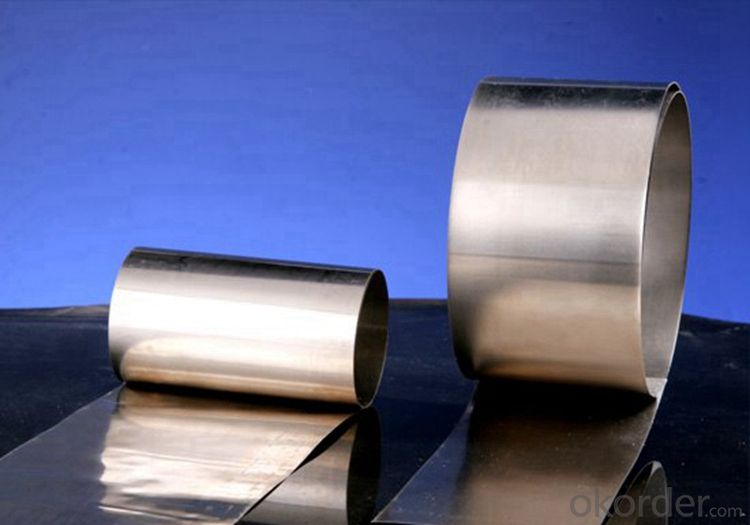

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: Are stainless steel sheets magnetic?

- Stainless steel sheets have the potential to be magnetic. The magnetic nature of stainless steel sheets relies on their composition. Generally, stainless steel is not magnetic. However, specific grades, such as the 400 series (such as 410, 416, 420, and 430), may possess magnetic properties due to a higher presence of ferritic or martensitic structures. Conversely, the commonly used 300 series stainless steel (such as 304 and 316) is non-magnetic because of its austenitic structure. Thus, it is crucial to consider the specific grade of stainless steel when assessing its magnetic behavior.

- Q: Can stainless steel sheets be used for roofing?

- Yes, stainless steel sheets can be used for roofing. Stainless steel is highly durable, corrosion-resistant, and can withstand extreme weather conditions, making it a suitable material for roofing applications.

- Q: What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on various factors such as size, thickness, grade, and quantity. It is best to contact a supplier or check online marketplaces to get a specific and up-to-date price for stainless steel sheets.

- Q: 1mm how much is the thickness of the 304 stainless steel sheet a square?

- 1mm 304 stainless steel plate, about 160 yuan a square, this may be based on your amount to determine the amount of large, you can also pay the price, the amount of small may not be. Jiashan Rongchang sliding bearings can also provide 1mm 304 stainless steel plate self lubrication skateboards, it is composed of 3 layers

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: How are stainless steel sheets finished?

- To achieve different appearances and textures, there are various ways to finish stainless steel sheets. The most common techniques for finishing stainless steel sheets are as follows: 1. Mill Finish: Stainless steel sheets have a dull, non-reflective surface with visible grain lines as a result of the manufacturing process. This is the standard finish when the sheets are first produced. 2. Brushed Finish: Also known as satin finish, this involves brushing the surface of the stainless steel with an abrasive material to create a consistent, fine grain appearance. It produces a smooth and matte finish, which is often preferred for aesthetic reasons. 3. Mirror Finish: This finish creates a highly reflective and mirror-like surface on the stainless steel sheets. It is achieved by progressively polishing the surface with finer abrasive materials until a smooth and reflective finish is achieved. 4. Embossed Finish: This technique involves impressing a pattern or design onto the surface of the stainless steel sheets. Heat and pressure are used to create raised or recessed patterns, adding texture and visual interest to the sheets. 5. Bead Blasted Finish: Fine glass beads or other abrasive materials are used to blast the surface of the stainless steel sheets. This creates a uniform, matte appearance with a slightly textured finish. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or alloy is vaporized and deposited onto the surface of the stainless steel sheets. This coating enhances the appearance of the sheets, offering various colors and finishes such as gold, bronze, or black. In summary, the choice of finish for stainless steel sheets depends on the desired aesthetic, functionality, and application of the material. Each finish has its own unique characteristics, allowing for versatility and customization in various industries, including architecture, interior design, automotive, and more.

- Q: What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, surface finish, thickness, and any surface treatments or coatings applied. It is typically higher than that of carbon steel, making stainless steel sheets more resistant to fatigue failure under cyclic loading. However, the exact fatigue strength value will vary and can be determined through testing and analysis specific to the particular stainless steel sheet being used.

- Q: What's the difference between stainless steel coil and stainless steel plate?

- One is a coil and the other is a strip.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, you can take several measures. Firstly, ensure that the sheets are properly cleaned and free from any contaminants before installation. This includes removing any oils, dirt, or other substances that may contribute to corrosion. Additionally, applying a corrosion-resistant coating or a protective film can act as a barrier against fretting corrosion. It is also important to avoid excessive mechanical stress or movement between the sheets, as this can lead to fretting corrosion. Finally, maintaining a dry and clean environment, with controlled humidity levels, can significantly reduce the risk of fretting corrosion on stainless steel sheets.

Send your message to us

Prime Quality Stainless Steel 201 Grade Stainless Steel Sheets For Construction Building Metals

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords