1 4 Inch Aluminum Bar Stock

1 4 Inch Aluminum Bar Stock Related Searches

1 4 X 1 4 Aluminum Bar Stock 1 4 Aluminum Bar Stock 1 2 X 3 4 Aluminum Bar Stock 1 Inch Aluminum Bar Stock 1 8 X 1 4 Aluminum Bar Stock 1/4 X 1/4 Aluminum Bar Stock 1/4 Aluminum Bar Stock 1 4 Inch Aluminum Flat Stock 1 Aluminum Bar Stock 3 4 Aluminum Bar Stock 1 X 2 Aluminum Bar Stock 3/4 Aluminum Bar Stock 1 2 X 1 2 Aluminum Bar Stock 1 2 Aluminum Bar Stock 2 Inch Aluminum Bar Stock 3 Inch Aluminum Bar Stock Stock Aluminum Bar 1/2 X 3/4 Aluminum Bar Stock 1 8 X 1 Aluminum Bar Stock 3 4 X 3 8 Aluminum Bar Stock Aluminum Stock Bar 1 Inch Square Aluminum Stock 1 8 Aluminum Bar Stock Aluminum Bar Stock 1 2 1 4 Inch Aluminum Plate 1 Inch Aluminum Square Stock 2 Aluminum Bar Stock 3/4 X 3/8 Aluminum Bar Stock 3/8 Aluminum Bar Stock Aluminum Bar Stock For Sale1 4 Inch Aluminum Bar Stock Supplier & Manufacturer from China

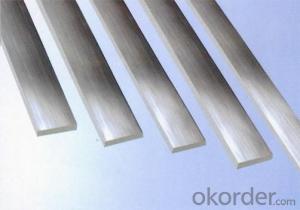

1/4 Inch Aluminum Bar Stock is a versatile product that consists of aluminum bars with a diameter of 1/4 inch. These bars are made from high-quality aluminum alloy, making them lightweight, durable, and corrosion-resistant. They are widely used in various industries, such as aerospace, automotive, construction, and manufacturing, for applications that require strength, flexibility, and resistance to harsh environments.The 1/4 Inch Aluminum Bar Stock is ideal for a wide range of applications, including structural components, brackets, frames, and other mechanical parts. Due to its excellent strength-to-weight ratio, it is particularly popular in industries where weight is a critical factor, such as in the aerospace and automotive sectors. Additionally, its resistance to corrosion makes it suitable for use in outdoor applications and in environments with high humidity or exposure to chemicals.

Okorder.com is a leading wholesale supplier of 1/4 Inch Aluminum Bar Stock, offering a large inventory of this product to cater to the needs of various industries. As a reputable supplier, Okorder.com ensures that the aluminum bar stock they provide meets the highest quality standards, ensuring that customers receive a reliable and durable product for their specific applications.

Hot Products