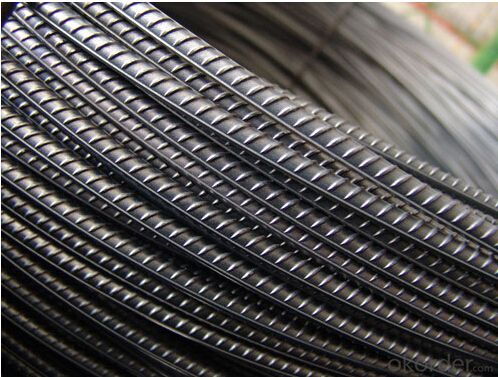

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | ASTM,BS,GB,KS,GB, BS ,KS, ASTM | Grade: | HRB400 | Diameter: | 6mm-40mm |

| Length: | 6-12meters,6m-12m | Place of Origin: | Hebei China (Mainland) | Brand Name: | Haixing |

| Model Number: | FHX | Application: | construction | color: | black |

| Package: | Within bundles | Thechique: | hot rolled |

Packaging & Delivery

| Packaging Detail: | MIill's export standard packing in bundles with wire rod as customer's requirement |

| Delivery Detail: | within 30 days |

Specifications

Certificates: CE & ISO9001:2000

Material: hrhrb400 ,hrb500, BS4449, ASTM A615, SD400

length:6-12

Size: 6mm-40mm

Product Description Material: HRB400,HRB500, BS4449,ASTM A615 GR40/60, SD400 usuage: building and construction |

- Q: What is the process of epoxy-coating steel rebars?

- To achieve a durable and corrosion-resistant coating on steel rebars, several steps are involved in the process of epoxy-coating. Here is a general overview of the process: Firstly, the steel rebars undergo thorough surface preparation to eliminate any rust, oil, or other contaminants. This can be accomplished through techniques such as sandblasting or chemical cleaning. Once the rebars are cleaned, a primer is applied to enhance adhesion between the steel surface and the epoxy coating. Additionally, the primer provides an extra layer of protection against corrosion. After the primer has dried, the epoxy coating is applied to the rebars. This can be done using various methods, including spray application or immersing the rebars in an epoxy tank. Following the application of the epoxy coating, the rebars are left to cure. This controlled process allows the coating to harden and fully bond with the steel surface. The curing time varies depending on the specific epoxy and environmental conditions. Once the rebars have cured, a thorough inspection is conducted to ensure the uniform application of the epoxy coating and that it meets the required specifications. This inspection may involve visual checks, adhesion tests, and measurements of coating thickness. After passing inspection, the epoxy-coated steel rebars are packaged and stored in a controlled environment to protect them from damage or further contamination. It is important to note that the specific process may vary depending on factors such as the manufacturer, project requirements, and the type of epoxy coating used. Following industry standards and guidelines is crucial to ensure the quality and effectiveness of the epoxy-coated steel rebars.

- Q: What are the different types of steel rebars used in bridge piers?

- The different types of steel rebars commonly used in bridge piers include epoxy-coated rebars, galvanized rebars, stainless steel rebars, and carbon steel rebars.

- Q: Are there any safety precautions when handling steel rebars?

- When handling steel rebars, it is important to adhere to several safety precautions. Consider the following important measures: 1. Personal Protective Equipment (PPE): Ensure that the appropriate PPE is worn at all times. This includes safety glasses or goggles, gloves, steel-toed boots, and a hard hat. These items will protect against potential hazards such as falling objects, sharp edges, or flying debris. 2. Proper Lifting Techniques: Due to the weight and awkwardness of steel rebars, it is essential to utilize proper lifting techniques. This involves bending at the knees and maintaining a straight back while lifting. Avoid sudden twisting or jerking movements that could strain muscles or cause injury. 3. Secure Storage and Handling: To prevent rebars from falling or rolling, it is crucial to store and stack them in a stable and secure manner. Utilize appropriate storage racks or containers that will ensure safe storage and eliminate risks to workers or equipment. 4. Tripping Hazards: Ensure that work areas are free from tripping hazards, such as loose rebars or debris. Secure rebars in place to prevent unexpected rolling or shifting. 5. Cutting and Bending: When cutting or bending steel rebars, use the proper tools and machinery specifically designed for these tasks. Adhere to proper procedures and ensure that the work area is clear of other workers to prevent accidents or injuries. 6. Communication and Training: Clearly communicate and provide training to all workers involved in handling steel rebars. This includes educating them about safety precautions, proper equipment usage, and emergency procedures. By following these safety precautions, the risk of accidents, injuries, and damage when handling steel rebars can be significantly reduced. Prioritizing safety in every aspect of the job is essential to ensure the well-being of workers and the successful completion of the project.

- Q: Can steel rebars be used in dams and reservoirs?

- Yes, steel rebars can be used in dams and reservoirs. Steel rebars are commonly used in the construction of dams and reservoirs to provide structural reinforcement and strength to the concrete structures. The rebars are embedded within the concrete to enhance its tensile strength and prevent cracks or failure.

- Q: What are the factors to consider when choosing the right steel rebar for a project?

- When selecting the appropriate steel rebar for a project, several factors need to be taken into consideration. These factors include the type of project, the structural requirements, the environment, and the specific characteristics of the rebar. One of the key factors to consider is the type of project. Different projects, such as residential buildings, bridges, or highways, have varying structural requirements. The steel rebar selected should be able to withstand the anticipated loads and stresses of the project. Additionally, the size and shape of the rebar should also align with the project's design and specifications. Structural requirements play a vital role in choosing the right steel rebar. This includes considering the required tensile strength, yield strength, and elongation properties. It is crucial to select a rebar that can provide the necessary strength and durability to ensure the structural integrity of the project. The environment in which the project will be located is another significant factor. If the project is exposed to corrosive elements, such as saltwater or chemicals, it is important to choose a rebar with corrosion-resistant properties. This can prevent premature deterioration and maintain the longevity of the structure. Furthermore, the specific characteristics of the rebar need to be evaluated. This includes the grade of the steel, which determines its strength and ductility. Different grades, such as ASTM A615 or ASTM A706, have distinct properties that suit various applications. The surface finish of the rebar, such as plain or deformed, also affects its bonding ability with concrete. Other factors that should be taken into account include the availability and cost of the steel rebar. It is crucial to ensure that the selected rebar is readily available and can be obtained in the required quantities and sizes. Additionally, the cost of the rebar should align with the project's budget constraints. In conclusion, when choosing the right steel rebar for a project, it is essential to consider factors such as the type of project, structural requirements, environmental conditions, and specific characteristics of the rebar. By carefully considering these factors, one can select the most suitable steel rebar that ensures the durability and longevity of the structure.

- Q: How are steel rebars identified and marked?

- Steel rebars are identified and marked through various methods including embossed markings, painted markings, and tagging systems. These identification marks typically include relevant information such as the grade of steel, manufacturer's logo, batch number, and bar size.

- Q: How are steel rebars cut on-site?

- Steel rebars are typically cut on-site using a variety of tools such as a rebar cutter or a portable hydraulic shear. These tools are specifically designed to provide precise and efficient cutting of steel rebars, ensuring that they are accurately sized for construction purposes.

- Q: What are the main properties of steel rebars?

- Steel rebars, also known as reinforcing bars, are essential components in reinforced concrete structures. They possess several key properties that make them ideal for providing strength and durability to these structures. 1. Strength: One of the primary properties of steel rebars is their high tensile strength. They can withstand significant pulling forces and provide the necessary reinforcement to resist cracking and structural failure in concrete. 2. Ductility: Steel rebars exhibit excellent ductility, meaning they can deform without fracturing under stress. This property allows them to absorb energy during seismic events or other extreme loads, enhancing the overall structural performance and resilience of the reinforced concrete. 3. Corrosion resistance: Steel rebars are typically manufactured with a protective layer, such as epoxy or galvanized coating, to prevent corrosion. This property is crucial as exposure to moisture, chloride ions, and other corrosive elements can significantly weaken the rebars and compromise the integrity of the structure. 4. Weldability: Steel rebars can be easily welded together, allowing for efficient and effective construction. This property ensures that rebars can be connected to form a continuous and robust reinforcement network, enhancing the overall strength and stability of the concrete structure. 5. Thermal compatibility: Steel rebars have similar thermal expansion and contraction properties to concrete, minimizing the risk of cracking or structural damage due to temperature changes. This compatibility ensures the long-term durability and stability of reinforced concrete structures. 6. Availability and cost-effectiveness: Steel rebars are widely available and relatively cost-effective compared to other reinforcing materials. This affordability, combined with their excellent mechanical properties, makes them a popular choice for structural reinforcement across various construction projects. In conclusion, the main properties of steel rebars include high tensile strength, ductility, corrosion resistance, weldability, thermal compatibility, and cost-effectiveness. These properties make steel rebars indispensable for providing structural strength and durability to reinforced concrete structures.

- Q: Can steel rebars be used in pre-stressed concrete elements?

- Yes, steel rebars can be used in pre-stressed concrete elements. Rebars are often used to provide additional reinforcement and strength to pre-stressed concrete structures, helping to counteract the tensile forces that may be induced during the pre-stressing process.

- Q: What are the guidelines for repairing damaged steel rebars in a structure?

- The guidelines for repairing damaged steel rebars in a structure typically involve a few key steps. Firstly, it is important to assess the extent of the damage and determine if the rebars can be repaired or need to be replaced entirely. If repair is feasible, the damaged portion of the rebar should be carefully cut out, ensuring that the surrounding concrete is not affected. The surface of the remaining rebar should then be prepared by removing any rust, scale, or contaminants. Next, an appropriate repair material, such as epoxy or a cementitious grout, should be applied to bond the repaired rebar with the existing structure. The repaired area should be properly cured and protected to ensure its long-term durability. It is crucial to follow industry standards and consult with structural engineers or professionals experienced in rebar repair to ensure the repair is done correctly and meets the necessary requirements for structural integrity.

Send your message to us

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords