Q235B steel flat for construction with good

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Spring Steel can be divided into two types. One is carbon spring steel, and other one is alloy spring steel.

Alloy spring steel is based on carbon spring steel, by adding one or more alloying elements to improve the mechanical properties, hardenability and other properties to meet the requirement for manufacturing all kinds of spring steel.

Specification of Flat Spring Steel:

-Material: 55Si2Mn

-Production: Hot rolled or cold rolled

-Standard: GB/T 1222-1984

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Si | Mn | S |

0.52~0.6 | 1.500~2.00 | 0.60~0.90 | ≤0.035 |

P | Cr | Ni | Cu |

≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

Usage/Applications of Flat Spring Steel:

-Elements Si and Mn improve elasticity strength, hardenability, and the ratio of yield point and tensile strength. but the decarburization tendency is a little large,

-55Si2Mn Spring Steel can be used as vibration damper leaf spring and spiral spring of cars and tractors.

-Heat-resisting spring below 250 degrees.

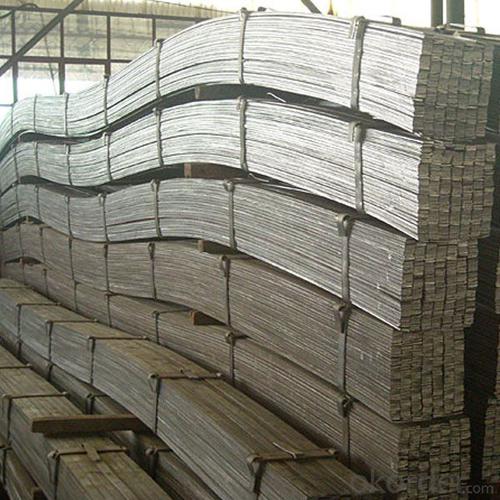

Packaging & Delivery of Flat Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

- Q: Are steel flat bars resistant to fire or heat?

- Yes, steel flat bars are highly resistant to fire and heat due to their high melting point and thermal conductivity.

- Q: What is the typical shear strength of steel flat bars?

- The typical shear strength of steel flat bars can vary depending on the specific grade and thickness of the material. However, in general, steel flat bars have a shear strength ranging from 40,000 to 60,000 pounds per square inch (psi). It is important to note that these values may differ based on factors such as the heat treatment, composition, and manufacturing processes used for the steel flat bar.

- Q: What are the different standards for steel flat bars?

- Steel flat bars, also known as steel flats or flats, are available in a variety of standards that determine their size, shape, and composition. These standards are established to guarantee consistency and excellence in the production and utilization of steel flat bars. One highly recognized standard for steel flat bars is the ASTM A36, which outlines the prerequisites for carbon structural steel. This standard specifies the chemical composition, mechanical properties, and dimensional tolerances for steel flats used in general structural purposes. Another frequently used standard is the ASTM A108, which covers carbon steel bars for general applications. This standard categorizes steel flat bars into different grades based on their chemical composition and mechanical properties. For more specialized applications, there are specific standards tailored to different industries. For example, the ASTM A276 is a standard that pertains to stainless steel bars and shapes. Within this standard, there are specific requirements for stainless steel flat bars, including their chemical composition, mechanical properties, and dimensions. In addition to ASTM standards, there are also international standards that govern the production and use of steel flat bars. The most notable one is the EN 10058, a European standard that specifies the tolerances on dimensions and shape for hot-rolled steel flat bars. Moreover, there are regional or national standards that may apply in certain countries. For instance, the JIS G3194 is a Japanese industrial standard that provides specifications for hot-rolled steel flat bars used in general structures. These standards are crucial to ensure the quality, compatibility, and interchangeability of steel flat bars in different applications. Manufacturers, engineers, and users rely on these standards to choose and work with steel flat bars that meet their specific requirements and adhere to industry norms.

- Q: What are the different types of protective coatings for steel flat bars?

- There are several types of protective coatings available for steel flat bars, each with its own specific characteristics and applications. Some of the most common types of protective coatings for steel flat bars include: 1. Galvanized Coatings: Galvanized coatings are one of the most popular options for protecting steel flat bars. This process involves dipping the steel in a bath of molten zinc, which forms a protective layer on the surface. Galvanized coatings provide excellent corrosion resistance and are often used in outdoor or marine environments. 2. Powder Coatings: Powder coatings are a type of protective coating that is applied as a dry powder and then cured under heat to form a hard, durable finish. These coatings offer excellent resistance to corrosion, chemicals, and UV rays. Powder coatings are available in a wide range of colors and finishes, making them ideal for decorative applications. 3. Epoxy Coatings: Epoxy coatings are known for their excellent adhesion and resistance to corrosion, abrasion, and chemicals. These coatings consist of an epoxy resin and a hardener, which react chemically to form a tough, protective layer on the steel flat bar. Epoxy coatings are commonly used in industrial settings or where heavy-duty protection is required. 4. Polyurethane Coatings: Polyurethane coatings provide a high level of durability and resistance to abrasion, chemicals, and UV rays. These coatings are often used in applications where the steel flat bars are exposed to harsh environmental conditions or heavy traffic. Polyurethane coatings are available in different finishes, including glossy and matte. 5. Chrome Coatings: Chrome coatings, also known as chrome plating, involve electroplating a thin layer of chromium onto the surface of the steel flat bar. This process provides excellent corrosion resistance and enhances the appearance of the steel. Chrome coatings are commonly used in decorative applications or where a highly reflective surface is desired. 6. Paint Coatings: Paint coatings are a cost-effective option for protecting steel flat bars. These coatings can be applied using brushes, rollers, or spray guns and are available in various colors and finishes. While paint coatings offer some level of protection against corrosion, they may require regular maintenance and touch-ups to maintain their effectiveness. It is important to consider the specific requirements of the steel flat bars' environment and intended use when selecting a protective coating. Factors such as exposure to moisture, chemicals, UV rays, and mechanical stress should be taken into account to ensure the most suitable coating is chosen for optimal protection and longevity.

- Q: Can steel flat bars be used for making brackets or supports for HVAC systems?

- Yes, steel flat bars can be used for making brackets or supports for HVAC systems. Steel flat bars are known for their strength and durability, which makes them suitable for providing sturdy support and stability to HVAC components.

- Q: What are the benefits of using steel flat bars in architectural projects?

- There are several benefits of using steel flat bars in architectural projects. Firstly, steel flat bars offer high tensile strength and exceptional durability, making them suitable for supporting heavy loads and withstanding harsh weather conditions. Secondly, their versatility allows for various applications such as framing, support structures, and decorative elements. Additionally, steel flat bars are malleable, making it easier to shape and customize according to specific project requirements. Moreover, steel's corrosion resistance minimizes the need for regular maintenance and ensures long-term performance. Lastly, steel is a sustainable and environmentally friendly material, as it can be recycled indefinitely without losing its properties, reducing the overall environmental impact of architectural projects.

- Q: Can steel flat bars be machined?

- Indeed, it is possible to machine steel flat bars. Machining entails utilizing machine tools to shape, cut, or drill a material. Steel, being a versatile substance, can be readily machined to fulfill specific requirements. To machine steel flat bars, one must employ a range of tools including lathes, mills, drills, and grinders to cut, shape, or generate holes in the metal. Nonetheless, it is crucial to acknowledge that the machinability of steel can differ based on its composition, hardness, and heat treatment. To attain the desired outcomes when machining steel flat bars, it is imperative to select the appropriate tools, cutting speeds, and feeds.

- Q: Can steel flat bars be used for making shelving or storage units?

- Steel flat bars are a versatile choice for constructing shelving or storage units due to their durability and strength. They are capable of holding heavy items and enduring frequent use. Moreover, steel flat bars offer the flexibility to create customized storage solutions through welding or bolting, ensuring a perfect fit for specific needs and spaces. In addition to their practicality, the sleek and modern appearance of steel flat bars adds an aesthetic appeal to shelving or storage units, making them suitable for both residential and commercial settings. Ultimately, steel flat bars serve as a dependable and robust foundation for building long-lasting and functional shelving or storage units.

- Q: What is the difference between a steel flat bar and a steel square tube?

- A steel flat bar and a steel square tube are both forms of steel materials commonly used in construction and manufacturing. However, they differ in their shape and structural properties. The main difference lies in their cross-sectional shape. A steel flat bar has a rectangular shape with two flat parallel surfaces and straight edges, while a steel square tube has a hollow square shape with four equal sides and thicker walls. In terms of structural properties, a steel flat bar is typically used for its strength in resisting bending or flexing. It is often used as a support or reinforcement in construction projects, such as for framing or bracing purposes. On the other hand, a steel square tube offers greater strength and rigidity due to its hollow structure. It is commonly used as a structural component for load-bearing applications, such as in building frameworks, machinery, or in the manufacturing of furniture. Additionally, the manufacturing process for these two steel forms can differ. Steel flat bars are usually produced by hot rolling, which involves heating the steel billet and passing it through a series of rolling stands. This process results in a flat shape with smooth surfaces. In contrast, steel square tubes are typically manufactured through a process called electric resistance welding (ERW), where a flat strip of steel is formed into a tube shape and then welded along the edges. In summary, while both steel flat bars and steel square tubes are made of the same material, their shape and structural properties make them suitable for different applications. Steel flat bars are commonly used for support and reinforcement purposes, while steel square tubes are preferred for load-bearing applications due to their greater strength and rigidity.

- Q: Can steel flat bars be used for making furniture or fixtures?

- Yes, steel flat bars can be used for making furniture or fixtures. They provide durability, strength, and a sleek modern aesthetic to the finished product. Steel flat bars can be shaped, welded, and finished to create various furniture designs such as tables, chairs, shelving units, and fixtures like towel racks or hooks.

Send your message to us

Q235B steel flat for construction with good

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords