1/4 X 1/4 Aluminum Bar Stock

1/4 X 1/4 Aluminum Bar Stock Related Searches

1/4 Aluminum Bar Stock 1 4 X 1 4 Aluminum Bar Stock 1/2 X 3/4 Aluminum Bar Stock 1 4 Inch Aluminum Bar Stock 3/4 Aluminum Bar Stock 1 2 X 3 4 Aluminum Bar Stock 1 4 Aluminum Bar Stock 1/4 Aluminum Angle Stock 1 8 X 1 4 Aluminum Bar Stock 1/2 X 1/2 Aluminum Bar Stock 3/4 X 3/8 Aluminum Bar Stock 1 1/4 Aluminum Round Stock 1/2 Aluminum Bar Stock 1 X 2 Aluminum Bar Stock 1 Inch Aluminum Bar Stock 3 4 Aluminum Bar Stock 3/4 Aluminum Square Stock 1 2 X 1 2 Aluminum Bar Stock 1/4 Aluminum Plate 1/4 Plate Aluminum 3/8 Aluminum Bar Stock 3/4 Aluminum Round Stock 1/4 Inch Aluminum Plate 1 4 Inch Aluminum Flat Stock Aluminum 1/4 Plate 1/4 Aluminum Plate For Sale 1 Aluminum Bar Stock 3 4 X 3 8 Aluminum Bar Stock Aluminum Plate 1/4 1 8 X 1 Aluminum Bar Stock1/4 X 1/4 Aluminum Bar Stock Supplier & Manufacturer from China

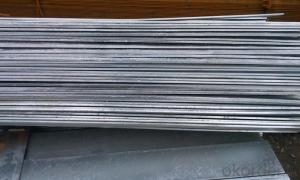

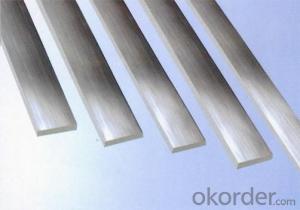

1/4 X 1/4 Aluminum Bar Stock is a type of aluminum material that comes in the form of a rectangular bar with dimensions of 1/4 inch by 1/4 inch. This product is known for its lightweight properties, high strength, and excellent corrosion resistance, making it a popular choice for various industries and applications.The 1/4 X 1/4 Aluminum Bar Stock is widely used in numerous industries, including aerospace, automotive, construction, and manufacturing. It is particularly favored for its ability to withstand high temperatures and maintain its structural integrity, making it ideal for applications that require heat resistance and durability. Additionally, this aluminum bar stock is frequently utilized in the production of various components, such as brackets, frames, and other structural elements that require a combination of strength and lightweight characteristics.

Okorder.com is a leading wholesale supplier of 1/4 X 1/4 Aluminum Bar Stock, offering a vast inventory of this product to cater to the needs of various customers. As a reputable supplier, Okorder.com ensures that the aluminum bar stock they provide meets the highest quality standards and is sourced from reliable manufacturers. This allows customers to have access to a consistent and reliable supply of 1/4 X 1/4 Aluminum Bar Stock, enabling them to efficiently manage their projects and operations.

Hot Products