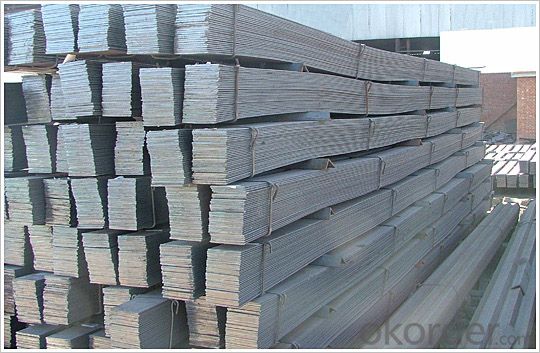

Good Quality Flat Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Material: steel

2) Grade: 304, 304L, 316, 316L, 310S, 904L, 2205, B2, C22, 625, etc.

3) Shape: Flat

4) Surface: Black, Hairline, Bright, Polished

5) Finish: Cold drawn, Hot rolled

6) Size:

a) Thickness: 2-20mm

b) Width: 15-200mm

7) Length: 1000mm-12000mm

8) Application: Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistant, electricity industries, etc.

9) Packing: Standard export packages, custom suffocating free.

10) Min order: 1 ton

11) Origin: China (Mainland)

12) Note: Stainless steel bars/rods can be made according to the customers' requirements.

| Material | 201 | 202 | 304 | 316 | 430 |

C | ≤ 0.15 | ≤ 0.15 | ≤ 0.08 | ≤ 0.08 | ≤ 0.12 | |

Si | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤ 2.00 | ≤ 2.00 | ≤ 1.00 | |

P | ≤ 0.06 | ≤ 0.06 | ≤ 0.045 | ≤ 0.045 | ≤ 0.040 | |

S | ≤ 0.03 | ≤ 0.03 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| |

Mo |

|

|

| 2.0-3.0 |

| |

| Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥ 535 | ≥ 520 | ≥ 520 | ≥ 520 | ||

Yield Strength | ≥ 245 | ≥ 205 | ≥ 205 | ≥ 205 | ||

Extension | ≥ 30% | ≥ 30% | ≥ 35% | ≥ 35% | ||

Hardness (HV) | < 253 | < 253 | < 200 | < 200 | ||

- Q: What are the different types of surface defects in stainless steel flat bars?

- There are various types of surface defects that can be found in stainless steel flat bars, which can be categorized into several groups. Some common surface defects in stainless steel flat bars include the following: 1. Pitting: Pitting refers to the formation of small, localized corrosion spots on the surface of stainless steel flat bars. These spots appear as small holes or pits and are usually caused by exposure to aggressive environments such as solutions containing chloride or acidic substances. 2. Scaling: Scaling occurs when oxide layers form on the surface of stainless steel flat bars due to exposure to high temperatures. This results in a flaky or powdery deposit and can happen during processes like heat treatment or welding. 3. Corrosion: Corrosion is the gradual deterioration of the stainless steel surface due to chemical reactions with the environment. It can take various forms, including uniform corrosion, crevice corrosion, or stress corrosion cracking, depending on the specific conditions and environment. 4. Scratches: Scratches are physical marks on the surface of stainless steel flat bars caused by abrasive contact or mechanical damage. They can vary in depth and severity, and if not addressed properly, they can create localized areas of stress concentration and potential sites for further corrosion. 5. Roll marks: Roll marks are imperfections on the surface of stainless steel flat bars that occur during the manufacturing process. They appear as irregular patterns or lines on the surface and are typically caused by the rolling or finishing equipment used in production. 6. Discoloration: Discoloration refers to changes in the appearance or color of the stainless steel flat bar surface. It can be caused by exposure to high temperatures, chemical reactions, or improper cleaning methods. Discoloration can manifest as light or dark patches, streaks, or a rainbow-like effect known as "heat tint" in cases of overheating during welding. It is important to emphasize that surface defects in stainless steel flat bars not only affect their visual appeal but also compromise their corrosion resistance, mechanical properties, and overall performance. Therefore, it is vital to promptly identify, assess, and address any surface defects to ensure the longevity and reliability of stainless steel flat bars.

- Q: Can steel flat bars be threaded?

- No, steel flat bars cannot be threaded as they do not have a hollow center like a pipe or a tube, which is necessary for threading.

- Q: Can steel flat bars be used for creating architectural facades or cladding?

- Yes, steel flat bars can be used for creating architectural facades or cladding. Steel is a versatile and durable material that can be shaped and manipulated to create various architectural elements. Steel flat bars can be used to create sleek and modern architectural facades or cladding, providing a clean and contemporary aesthetic to buildings. The flat bars can be cut, welded, and installed in different configurations to achieve different design patterns and textures. Additionally, steel is known for its strength and resistance to weathering, making it an ideal choice for exterior applications. Overall, steel flat bars offer a wide range of design possibilities and can be effectively used to create striking architectural facades or cladding.

- Q: How do steel flat bars contribute to the overall stability of structures?

- Steel flat bars contribute to the overall stability of structures by providing structural support and resistance against bending and torsional forces. They are commonly used as beams, braces, and frames, helping to distribute the load evenly and prevent the structure from collapsing or deforming under various loads and external pressures. Their inherent strength, durability, and rigidity make them crucial components in reinforcing and enhancing the stability and integrity of different types of structures, including buildings, bridges, and industrial frameworks.

- Q: How do you prevent burrs or sharp edges on steel flat bars during cutting?

- One way to prevent burrs or sharp edges on steel flat bars during cutting is to use a high-quality cutting tool or blade with sharp edges. Additionally, using a slower cutting speed and applying consistent pressure can help minimize the formation of burrs. Another effective method is to use cutting lubricants or coolant, which can reduce friction and heat during the cutting process, resulting in smoother edges. Regular maintenance and periodic sharpening of cutting tools are also crucial in preventing burrs and maintaining clean cuts.

- Q: Can steel flat bars be used for making window frames or door frames?

- Yes, steel flat bars can be used for making window frames or door frames. Steel flat bars provide strength, durability, and stability, making them suitable for such applications. They can be easily fabricated and welded to create sturdy frames that can withstand the weight and pressure of windows and doors.

- Q: What are the different methods of surface hardening for steel flat bars?

- There are several different methods of surface hardening for steel flat bars, each offering unique advantages and applications. Some of the most common methods include: 1. Flame Hardening: This process involves heating the surface of the steel flat bar with a flame and then quenching it rapidly, resulting in a hardened outer layer while retaining a tough core. Flame hardening is suitable for larger flat bars and offers good wear resistance. 2. Induction Hardening: In this method, an alternating electromagnetic field is used to heat the surface of the steel flat bar, followed by quenching. Induction hardening provides precise control over the hardened depth and is ideal for flat bars with complex geometries or smaller sizes. 3. Nitriding: Nitriding involves exposing the steel flat bar to a nitrogen-rich environment at elevated temperatures. This process forms a hard nitride layer on the surface, providing excellent wear and corrosion resistance. Nitriding is commonly used for flat bars that require superior surface hardness. 4. Carburizing: Carburizing involves heating the steel flat bar in a carbon-rich environment, allowing carbon atoms to diffuse into the surface. The part is then quenched to achieve hardness. Carburizing offers high wear resistance and is suitable for flat bars that require a hardened surface layer. 5. Carbonitriding: This method combines the benefits of both carburizing and nitriding. The steel flat bar is heated in a nitrogen-rich and carbon-rich atmosphere, resulting in a hard surface layer with improved wear and corrosion resistance. Carbonitriding is commonly used for flat bars that require a combination of hardness and toughness. 6. Laser Hardening: Laser hardening utilizes a high-energy laser beam to heat and rapidly cool the surface of the steel flat bar, creating a hardened layer. This process offers precise control over the hardened area and is suitable for flat bars with intricate designs or localized hardening requirements. Each surface hardening method has its own advantages and limitations, and the choice depends on the specific requirements of the steel flat bar application, such as desired hardness, wear resistance, and dimensional complexity.

- Q: What is flat steel, please?

- Steel strip steel rectangular and with pure edge of cold drawn steel, stainless steel flat steel. Stainless steel flat can be semi-finished steel. There are cold drawn polished stainless steel flat and hot-rolled acid white and sand blasting stainless steel flat. The raw material for producing stainless steel flat bar is stainless steel square billet, and the finished stainless steel flat bar is produced by hot rolling, normalizing or hot rolling, pickling (or sand blasting), cold drawing and polishing. The two sides are equal in width. The specifications are expressed in millimeters of edge width * * edge thickness. Such as 30 * 3, that is, width of 30 mm edge, 3 mm thick edge of stainless steel flat side.

- Q: What is the difference between a steel flat bar and a steel channel?

- A steel flat bar and a steel channel are both structural steel shapes, but they have distinct differences in their shape and design. A steel flat bar is a long, rectangular-shaped piece of steel with straight edges. It is commonly used in construction and manufacturing industries for various applications such as braces, supports, and frames. The flat surface of the bar provides stability and strength, making it suitable for load-bearing purposes. The width and thickness of a flat bar can vary depending on the specific requirements of a project. On the other hand, a steel channel is a C-shaped structural component with two flanges and a web in the middle. The flanges are perpendicular to the web, giving the channel its distinctive shape. Channels are widely used in construction, particularly in the framing of buildings and the creation of structural support systems. The flanges provide strength and rigidity to the channel, making it suitable for applications where lateral support and stability are required. In summary, the main difference between a steel flat bar and a steel channel lies in their shape and structural design. While a flat bar is a long, rectangular piece with straight edges, a channel has a C-shaped profile with flanges and a web. The choice between the two depends on the specific requirements of a project and the type of load-bearing or support function it needs to fulfill.

- Q: Can steel flat bars be used for making storage systems?

- Yes, steel flat bars can be used for making storage systems. Steel is a durable and strong material, making it suitable for creating storage systems that can withstand heavy loads and provide structural support. Steel flat bars can be used to construct shelves, racks, and frames for storage systems such as shelves in warehouses, display racks in retail stores, or even storage cabinets in homes or offices. Additionally, steel flat bars can be easily welded, cut, and shaped to meet specific design requirements, making them versatile for creating customized storage solutions.

Send your message to us

Good Quality Flat Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords