Cold Rolled Drawn Slit Cutting Steel Flat Bar for Re-Selling

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Cold Rolled Drawn Slit Cutting Steel Flat Bar Description:

Cold rolled drawn slit cutting steel flat bar is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Cold rolled drawn slit cutting steel flat bar is usually made of structural steel and is used in construction and civil engineering. The cold rolled drawn slit cutting steel flat bar resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Cold rolled drawn slit cutting steel flat bar theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Flat Bar Chinese Standard Slit and Cut Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

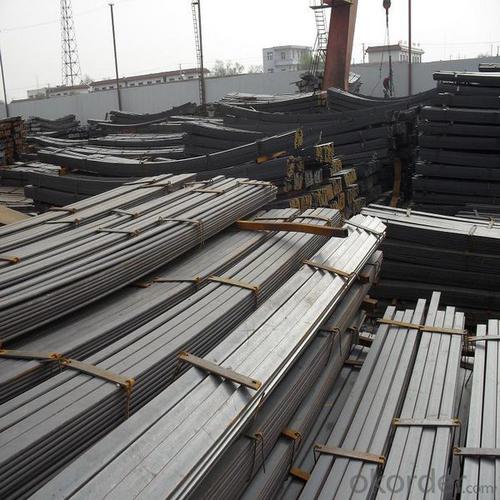

3. Steel Flat Bar Chinese Standard Slit and Cut Form Images:

4. Steel Flat Bar Chinese Standard Slit and Cut Form Specification:

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Are steel flat bars resistant to fire or heat?

- Steel flat bars are highly resistant to fire and heat. Steel is a non-combustible material, which means it does not burn or contribute to the spread of fire. In fact, steel has a high melting point, making it able to withstand extremely high temperatures without losing its structural integrity. This property is especially important in applications where fire resistance is critical, such as in the construction of buildings, bridges, and industrial equipment. Steel flat bars have been extensively tested and proven to maintain their strength and stability even under prolonged exposure to intense heat. Therefore, steel flat bars are considered a safe and reliable choice in fire-prone environments.

- Q: Are steel flat bars used in the construction of bridges or infrastructure?

- Yes, steel flat bars are commonly used in the construction of bridges and infrastructure. They provide structural support and stability, as well as being versatile and cost-effective. Steel flat bars are used in various applications such as beams, braces, and supports, and are known for their strength and durability, making them ideal for heavy-duty construction projects.

- Q: How do steel flat bars compare to other types of steel profiles?

- Steel flat bars have several advantages compared to other types of steel profiles. Firstly, they have a flat surface that makes them ideal for applications where a smooth and even support is required. This characteristic also allows for easy welding, cutting, and shaping, making them versatile for various construction and manufacturing projects. Additionally, steel flat bars offer excellent strength and durability, making them suitable for structural purposes. They are also cost-effective and readily available, making them a popular choice in the industry. Overall, steel flat bars provide a great balance of strength, versatility, and affordability, making them a preferred option among other types of steel profiles.

- Q: How do steel flat bars compare to other materials like aluminum or stainless steel?

- Steel flat bars have several advantages over other materials like aluminum or stainless steel. Firstly, steel is generally stronger and more durable than aluminum, making it ideal for heavy-duty applications where strength is a priority. Steel also has a higher tensile strength, making it less likely to bend or deform under pressure. In terms of cost, steel flat bars are usually more affordable than stainless steel. Stainless steel is known for its excellent corrosion resistance, but it comes at a higher price point. If corrosion resistance is not a primary concern, steel flat bars offer a cost-effective alternative without compromising on strength or durability. Steel flat bars are also highly versatile and can be easily welded, machined, or formed into various shapes and sizes. This versatility allows for a wide range of applications in industries such as construction, manufacturing, and automotive. However, it is important to note that stainless steel flat bars have their own unique advantages. Stainless steel offers superior resistance to corrosion, rust, and staining, making it ideal for applications in harsh environments or where hygiene is crucial, such as in food processing or medical equipment. On the other hand, aluminum flat bars have their own set of advantages as well. Aluminum is lightweight, non-magnetic, and has excellent thermal and electrical conductivity. It is commonly used in industries such as aerospace, automotive, and construction, where weight reduction and conductivity are important factors. In conclusion, steel flat bars offer a strong and cost-effective option for various applications. However, the choice between steel, aluminum, or stainless steel ultimately depends on the specific requirements of the project, including factors such as strength, corrosion resistance, cost, and conductivity.

- Q: Can steel flat bars be used in the manufacturing of machinery?

- Yes, steel flat bars can be used in the manufacturing of machinery. Steel flat bars are commonly used in the construction of machinery components due to their strength, durability, and versatility. They can be shaped, cut, and welded to create various machine parts such as brackets, supports, frames, and structural elements. Additionally, steel flat bars offer good resistance to impact, wear, and corrosion, making them suitable for industrial applications in the manufacturing sector.

- Q: Can steel flat bars be used for manufacturing tools or machinery?

- Yes, steel flat bars can be used for manufacturing tools or machinery. Steel is a highly versatile and durable material, making it suitable for a wide range of applications. Steel flat bars are commonly used in the manufacturing industry due to their strength, rigidity, and ability to withstand heavy loads and pressure. They can be easily shaped, welded, and machined to create various components and parts for tools and machinery. Additionally, steel flat bars are known for their excellent resistance to corrosion, which is crucial for ensuring the longevity and reliability of tools and machinery. Overall, steel flat bars are a popular choice in the manufacturing industry for their reliability, versatility, and suitability for producing high-quality tools and machinery.

- Q: Are steel flat bars suitable for indoor applications?

- Yes, steel flat bars are suitable for indoor applications. Steel flat bars are versatile and highly durable, making them ideal for various indoor uses. They can be used in construction, manufacturing, and furniture making, among other applications. Steel flat bars offer excellent strength and stability, making them suitable for supporting heavy loads or providing structural reinforcement. Additionally, they are resistant to corrosion and can withstand harsh indoor environments. Steel flat bars can be easily customized and fabricated to meet specific project requirements, making them a popular choice for indoor applications.

- Q: Construction of electrical grounding steel flat buried anti-corrosion requirements, galvanized steel flat welding parts should be done anti-corrosion treatment, not welding parts are also doing anti-corrosion treatment?

- The welding part needs to corrosion because in the welding process the heat melted metal surface coating, so this part, other parts such as did not cause damage to the galvanized layer in the construction process, there is no need for antiseptic treatment.

- Q: Can steel flat bars be used for making shelving or storage units?

- Yes, steel flat bars can be used for making shelving or storage units. Steel flat bars are known for their durability and strength, making them an excellent choice for constructing shelving or storage units that need to hold heavy items or withstand frequent use. Additionally, steel flat bars can be easily welded or bolted together to create customized storage solutions that fit specific needs and spaces. The sleek and modern appearance of steel flat bars also adds an aesthetic appeal to shelving or storage units, making them suitable for both residential and commercial settings. Overall, steel flat bars provide a sturdy and reliable foundation for creating durable and functional shelving or storage units.

- Q: How do steel flat bars contribute to the overall efficiency of healthcare structures?

- Steel flat bars contribute to the overall efficiency of healthcare structures in several ways. Firstly, steel flat bars are widely used in the construction of healthcare structures due to their strength and durability. This ensures that the buildings can withstand the test of time and provide a safe and secure environment for patients, staff, and equipment. Additionally, steel flat bars are highly versatile and can be easily fabricated into various shapes and sizes, allowing for efficient and precise construction. This enables healthcare structures to be designed and built according to specific requirements, optimizing the use of space and resources. Moreover, steel flat bars possess excellent fire resistance properties, which is crucial in healthcare structures where the safety of occupants is of utmost importance. By using steel flat bars in the construction, healthcare facilities can minimize the risk of fire incidents and ensure the protection of patients and staff. Furthermore, steel flat bars are known for their high load-bearing capacity, which is essential in healthcare structures that require the support of heavy equipment and machinery. This enables the buildings to accommodate advanced medical technology and infrastructure, such as MRI machines, surgical equipment, and patient lifts, without compromising structural integrity. Lastly, steel flat bars are relatively low-maintenance and resistant to corrosion, reducing the need for frequent repairs and replacements. This not only saves costs but also minimizes disruptions to healthcare services, allowing medical professionals to focus on providing quality care to patients. Overall, steel flat bars play a crucial role in enhancing the efficiency of healthcare structures by providing strength, versatility, fire resistance, load-bearing capacity, and low-maintenance characteristics.

Send your message to us

Cold Rolled Drawn Slit Cutting Steel Flat Bar for Re-Selling

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords