Grade 304 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade 304 Stainless Steel Round Bar in stock

Descriptio of Grade 304 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade 304 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade 304 Steel Round Bar in Stock

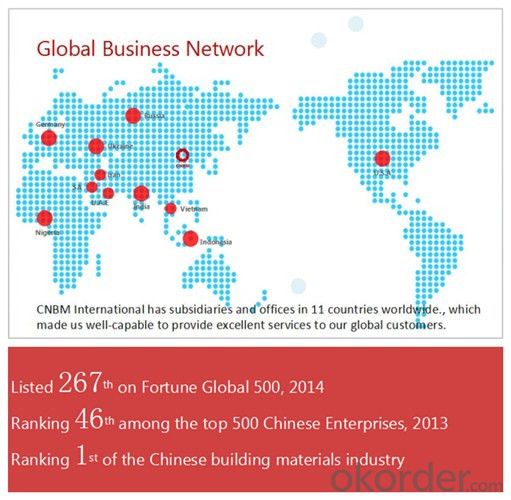

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade 304 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different shapes and forms in which special steel is available?

- Various shapes and forms of special steel are available to satisfy the diverse industrial and engineering needs. Some examples of special steel include: 1. Bars: Bars of special steel find extensive usage in the construction, automotive, and machinery sectors. They come in round, square, hexagonal, and flat shapes, providing design flexibility and ease of machining. 2. Sheets and Plates: Special steel sheets and plates are utilized in the production of robust components and structures. These sheets and plates are obtainable in different sizes and thicknesses, ensuring suitability for a wide range of applications. 3. Tubes and Pipes: Special steel tubes and pipes are commonly employed in industries like oil and gas, construction, and automotive. These tubes and pipes are available in various dimensions and can be either seamless or welded to meet specific requirements. 4. Wire: Special steel wire is extensively used for manufacturing springs, cables, fasteners, and other products that demand high tensile strength and corrosion resistance. It is available in different diameters and can undergo further processing techniques like drawing or annealing. 5. Forgings: Special steel can also be acquired in the form of forgings, which are shaped through controlled heating and mechanical pressure. Forgings possess exceptional strength and toughness, making them ideal for critical components in aerospace, power generation, and heavy machinery industries. 6. Castings: Special steel castings are produced by melting the steel and pouring it into molds. This casting process allows for the creation of intricate shapes and details, rendering castings suitable for applications in the automotive, energy, and mining sectors. 7. Profiles: Special steel profiles are tailor-made shapes that are specifically designed to fulfill unique engineering requirements. These profiles can be extruded, rolled, or cold-drawn, and are widely utilized in construction, transportation, and manufacturing industries. These examples merely scratch the surface of the diverse range of shapes and forms in which special steel is available. The selection of the most appropriate shape and form depends on the specific application and the desired mechanical properties required for the final product.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its high strength and ability to withstand sudden impact forces without fracturing or deforming. This steel is specifically designed to absorb and disperse energy, making it ideal for applications where parts are exposed to repeated impacts or high-stress environments. By using shock-resistant alloy steel, manufacturers can create durable and reliable impact-resistant parts that can withstand heavy loads, reduce the risk of failure, and increase the overall safety and longevity of the component or equipment.

- Q: What are the main advantages of using special steel in the automotive industry?

- The main advantages of using special steel in the automotive industry are its high strength-to-weight ratio, improved durability and resistance to corrosion, and enhanced crashworthiness. Special steel allows for the production of lighter vehicles without compromising safety, resulting in improved fuel efficiency and reduced emissions. Additionally, its superior mechanical properties make it suitable for critical components, enhancing the overall performance and reliability of automobiles.

- Q: What are the varieties of special steel

- China and Japan, the definition of special steel is relatively close, the special steel into high quality carbon steel, alloy steel, high alloy steel (alloy element is greater than 10%) three categories

- Q: What are the environmental benefits of using special steel?

- Special steel, also known as stainless steel, offers numerous environmental benefits. Firstly, it is highly durable and long-lasting, resulting in reduced waste and resource consumption over time. Additionally, stainless steel is 100% recyclable, allowing it to be repurposed indefinitely without any loss in quality. This recycling process requires significantly less energy compared to the production of new steel, leading to a considerable reduction in carbon emissions and environmental impact. Moreover, special steel is corrosion-resistant, eliminating the need for frequent replacements and reducing the use of resources and energy associated with maintenance. Overall, the environmental benefits of using special steel include decreased waste generation, lower energy consumption, reduced carbon emissions, and increased resource efficiency.

- Q: What are the different methods for controlling the grain size in special steel?

- There are several methods for controlling the grain size in special steel. One common method is through the use of alloying elements such as vanadium or niobium, which can help refine the grain structure. Another approach is to employ controlled cooling techniques, such as quenching or tempering, to manipulate the rate at which the steel solidifies and thus control the grain size. Additionally, grain size can be influenced by the addition of grain refiners or by subjecting the steel to severe plastic deformation processes like rolling or forging. Overall, these methods allow for precise control over the grain size in special steel, enabling improved mechanical properties and performance.

- Q: What are the physical properties of special steel?

- Special steel is a type of steel that possesses unique physical properties compared to regular steel. These properties may vary depending on the specific composition and processing techniques used. However, some common physical properties of special steel include high strength, hardness, and durability. Special steel is often designed to withstand extreme conditions such as high temperatures, pressure, and corrosive environments. It may also exhibit excellent wear resistance, making it suitable for applications involving heavy machinery or cutting tools. Furthermore, special steel can have superior electrical and thermal conductivity, as well as good magnetic properties. Overall, the physical properties of special steel make it highly versatile and valuable in various industries such as automotive, aerospace, construction, and energy.

- Q: How does special steel perform in aerospace applications?

- Due to its exceptional performance and unique properties, special steel finds extensive use in aerospace applications. A primary reason for its usage lies in its high strength-to-weight ratio, a crucial factor in the aerospace industry where weight reduction is of utmost importance. Special steel alloys exhibit superior strength, enabling them to withstand the extreme conditions experienced during flight, including high temperatures, vibrations, and pressure changes. Moreover, special steel possesses excellent corrosion resistance, making it an ideal choice for aerospace applications where exposure to moisture and various chemicals is common. Its corrosion resistance ensures the durability and longevity of critical components, resulting in reduced maintenance and replacement costs. Furthermore, special steel offers excellent fatigue resistance, allowing it to endure repeated loading and unloading cycles without deformation or failure. This property is vital in aerospace applications where components must withstand cyclic stresses and maintain their integrity for extended periods. Additionally, special steel alloys can be readily fabricated and machined, facilitating the production of intricate and precise aerospace components. The ease of fabrication ensures efficient manufacturing processes and the ability to create complex designs, which are essential for optimizing performance and aerodynamics. In conclusion, special steel's exceptional strength, corrosion resistance, fatigue resistance, and ease of fabrication make it an invaluable material in aerospace applications. Its utilization in critical components, such as turbine blades, landing gears, and structural elements, guarantees the safety, reliability, and efficiency of aerospace systems.

- Q: Can special steel be machined easily?

- No, special steel is typically harder and more difficult to machine compared to regular steel due to its higher alloy content and specific properties.

- Q: What are the main challenges in machining special steel?

- The main challenges in machining special steel include its high hardness and toughness, which can lead to increased tool wear and reduced cutting speeds. Special steel also tends to have low thermal conductivity, making it prone to heat buildup during machining, resulting in thermal damage to the workpiece and tools. Additionally, the presence of alloying elements in special steel can cause work hardening and increased cutting forces, demanding more robust machining techniques and tools.

Send your message to us

Grade 304 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords