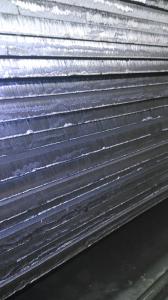

Prime Flat Bars Slitted with Variety Size and Thichness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Prime Flat Bars Slitted with Variety Size and Thichness at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Prime Flat Bars Slitted with Variety Size and Thichness are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Prime Flat Bars Slitted with Variety Size and Thichness are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How many tons of steel products could be loaded in containers?

A2: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: Are steel flat bars used in the construction of bridges or infrastructure?

- Steel flat bars are frequently employed in the construction of bridges and infrastructure due to their versatility and strength. These bars can be utilized in various construction projects and are particularly useful as structural components in bridge construction, offering support and stability. Moreover, their strength and durability make them suitable for constructing buildings, roads, and railways. In construction projects that demand customization and flexibility, steel flat bars are preferred due to their ease of fabrication and welding. In summary, the construction industry extensively relies on steel flat bars for their reliability, strength, and versatility.

- Q: What are the different types of finishes available for steel flat bars?

- Steel flat bars offer a variety of finishes, each with their own advantages and aesthetic appeal. Here are some of the most common finishes: 1. Mill Finish: The standard finish for steel flat bars is achieved through hot rolling, resulting in a plain and smooth surface. This creates an industrial and clean look. 2. Hot Rolled Pickled and Oiled (HRPO): This finish involves an additional process where the steel flat bar is pickled in an acid bath to remove impurities, and then oiled to prevent rust. HRPO finish offers improved corrosion resistance and a slightly smoother surface. 3. Cold Rolled: For a smoother and more precise surface, the steel flat bar is passed through rollers at room temperature. Cold rolled finish is popular for applications requiring a high-quality appearance. 4. Galvanized: To protect against corrosion, the steel flat bar is coated with a layer of zinc. This galvanized finish is highly durable and suitable for outdoor use. 5. Powder Coated: A dry powder is applied to the steel flat bar and baked to create a strong and protective finish. Powder coating comes in various colors and offers excellent resistance to chipping, peeling, and fading. 6. Brushed: Achieved by rubbing the surface with a wire brush or abrasive material, a brushed finish creates a textured and satin-like appearance. It is often used for decorative purposes and helps conceal scratches or imperfections. 7. Polished: This finish involves grinding the surface to a smooth and reflective appearance. Polishing is commonly used in architectural or decorative applications for a high-end, mirror-like look. These examples highlight the range of finishes available for steel flat bars. The choice of finish depends on factors such as the intended use, desired appearance, and environmental conditions affecting corrosion resistance.

- Q: How do you join steel flat bars together?

- To connect steel flat bars, there exists a variety of methods, which depend on the intended application and desired strength of the connection. Here, we present a few commonly employed techniques: 1. Welding: Welding stands as one of the most favored methods, wherein heat and pressure are employed to fuse the flat bars. This results in a robust and enduring bond. Depending on specific requirements, various welding techniques like arc welding, MIG welding, or TIG welding can be utilized. 2. Bolting: An alternative approach involves the use of bolts or screws to link the steel flat bars. By drilling holes into the bars, bolts or screws can be inserted through them and then secured with nuts. This technique permits easy disassembly, if necessary. 3. Riveting: Riveting entails inserting a metal pin, referred to as a rivet, through holes in the flat bars. The rivet's end is then deformed or upset to ensure a secure connection. This method finds common usage in structural applications that necessitate high strength and resistance to vibrations. 4. Adhesive bonding: In certain cases, adhesive bonding can be employed to join steel flat bars. Specifically formulated adhesives designed for metal bonding are applied to the surfaces, and the bars are pressed together until the adhesive sets. This method proves suitable for lightweight applications or when welding is unfeasible. Prior to selecting the appropriate method for joining steel flat bars, it is crucial to consider the specific requirements of your project, such as load-bearing capacity, flexibility, and ease of disassembly. Additionally, it is advisable to consult with a professional or adhere to industry standards and guidelines to ensure a safe and dependable connection.

- Q: How do you determine the strength of a steel flat bar?

- There are several methods available for determining the strength of a steel flat bar. One commonly used approach is through tensile testing, which involves applying a pulling force on a specimen until it fractures. This test allows for the measurement of load, deformation, stress, and strain, which can then be used to calculate various mechanical properties such as yield strength, ultimate tensile strength, and elongation. Another method to assess the strength of a steel flat bar is through hardness testing. Hardness is a measure of the material's resistance to indentation or scratching, and it is often indicative of its overall strength. Popular hardness tests for steel include Brinell, Rockwell, and Vickers tests. Furthermore, the strength of a steel flat bar can also be determined by considering its chemical composition. Steel is primarily composed of iron and carbon, but other elements like manganese, chromium, and nickel are added to enhance specific properties. The composition and heat treatment of the steel can greatly influence its strength. It is worth noting that the bending properties of a steel flat bar, such as flexural strength, can also be assessed through tests like the three-point bending test or the four-point bending test. These tests determine the maximum load a specimen can withstand before breaking or yielding under bending forces. In summary, the strength of a steel flat bar can be determined using methods such as tensile testing, hardness testing, considering its chemical composition, and analyzing its bending properties. These approaches provide valuable insights into the steel's mechanical properties, enabling engineers and manufacturers to choose the most suitable steel grade for specific applications.

- Q: How do steel flat bars perform in extreme weather conditions?

- Steel flat bars are known for their exceptional strength and durability, which makes them highly resistant to extreme weather conditions. They are capable of withstanding high temperatures, heavy rain, snow, and even strong winds. In extreme heat, steel flat bars have a high melting point, which means they can withstand prolonged exposure to intense heat without warping or losing their structural integrity. This makes them ideal for applications in areas with high temperatures, such as deserts or industrial settings. During heavy rain or snowfall, steel flat bars are highly resistant to corrosion and do not rust easily. This makes them suitable for outdoor applications where they may be exposed to moisture for extended periods. Moreover, their smooth surface allows water to run off easily, preventing the accumulation of water and reducing the risk of damage caused by freezing and thawing cycles. In areas prone to strong winds or storms, steel flat bars are known for their exceptional strength and stability. They can withstand high wind pressures and resist bending or breaking, making them a reliable choice for structures such as fences, barriers, and support beams. However, it is important to note that even though steel flat bars are highly resistant to extreme weather conditions, they still require proper maintenance to ensure their longevity. Regular cleaning, inspection, and applying protective coatings can help prevent any potential damage or deterioration caused by weathering. Overall, steel flat bars are a reliable choice for applications in extreme weather conditions due to their strength, durability, and resistance to corrosion.

- Q: Earthing flat steel and earthing main line

- Grounding flat ground belongs to the material, the grounding line belongs to the grounding line, grounding flat steel used for grounding grid, the grounding line is also one of the flat ground, for connecting the grounding grid, the grounding grid extends to the metal shell of the substation ground of all electrical equipment, and the grounding grid connected together.

- Q: Construction of lightning protection ground galvanized flat steel approach, need to retest test? What's the test?

- Hot rolled flat steel is a general purpose rectangular cross section strip. Its specifications are expressed in millimeters of thickness / width, flat steel can be finished steel, used for components, ladders, bridges and fences, etc.. Flat steel can also be used to weld rigid steel and billets and slabs of laminated sheets. This standard is applicable to hot-rolled flat steel with rectangular cross section. Measurement: flat length and length of flat steel, according to the theoretical weight of delivery.

- Q: What are the different sizes of steel flat bars?

- The sizes of steel flat bars can vary depending on the manufacturer and the specific requirements of the project. However, common sizes of steel flat bars include widths ranging from 1/8 inch to 24 inches, and thicknesses ranging from 3/16 inch to 2 inches. These sizes provide a wide range of options to accommodate various applications in industries such as construction, manufacturing, and fabrication.

- Q: What are the different methods of bending steel flat bars?

- There are several different methods of bending steel flat bars, depending on the specific requirements and constraints of the project. Some of the most common methods include: 1. Manual bending: This method involves using a manual bending machine or tools such as a vise and hammer to bend the steel flat bar. It requires physical effort and precision to achieve the desired bend angle and shape. 2. Heat bending: Heat bending involves heating the steel flat bar to a high temperature using a torch or furnace, and then bending it while it is still hot. This method is useful for achieving tight or complex bends, as the heat softens the steel and makes it more malleable. 3. Roll bending: Roll bending is a method that uses specialized machines equipped with multiple rollers to gradually bend the steel flat bar. The flat bar is fed through the rollers, which apply pressure and gradually bend it to the desired shape. 4. Hydraulic bending: Hydraulic bending machines use hydraulic power to apply force and bend the steel flat bar. These machines are capable of achieving precise and consistent bends, and are often used for heavy-duty or industrial applications. 5. Press bending: Press bending involves using a press machine to apply force and bend the steel flat bar. This method is commonly used for larger and thicker flat bars, as the press can generate significant force. 6. Rotary draw bending: Rotary draw bending is a method that uses a bend die and a mandrel to bend the steel flat bar. The mandrel is inserted into the bar to prevent it from collapsing or deforming during the bending process, while the bend die shapes the bar to the desired angle. These are just a few of the many methods available for bending steel flat bars. The choice of method will depend on factors such as the desired bend angle, the thickness and size of the flat bar, and the available equipment and resources. It is always important to follow proper safety precautions and consult with professionals when working with steel bending techniques.

- Q: Are steel flat bars used in the manufacturing of agricultural machinery?

- Yes, steel flat bars are commonly used in the manufacturing of agricultural machinery. They are often utilized for various components such as frames, brackets, and supports due to their strength, durability, and versatility in different applications.

Send your message to us

Prime Flat Bars Slitted with Variety Size and Thichness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords