black galvanized steel flat bar hot rolled steel flat bar vertical flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

GB

Technique:

Hot Rolled,Cold Rolled

Shape:

flat bar

Surface Treatment:

Galvanized,Black

Steel Grade:

Q195,Q235B,Q355B,SS400,S235JR,ASTM A36

Certification:

SGS,BV

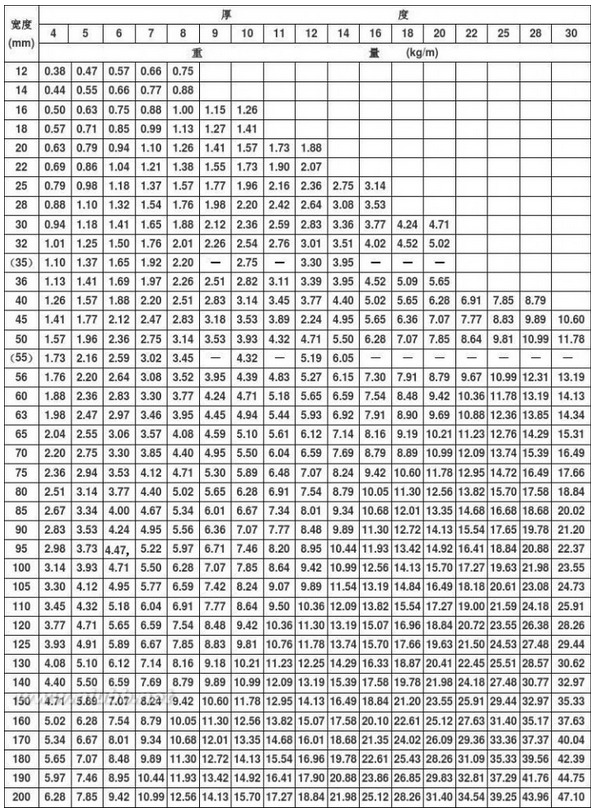

Thickness:

1.3-20MM

Width:

12-150MM

Length:

1-12m or customized

Net Weight:

0.122-23.55kg/m

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

- Q: Are steel flat bars suitable for outdoor signage or displays?

- Yes, steel flat bars are indeed suitable for outdoor signage or displays. Steel is a highly durable and weather-resistant material, making it ideal for withstanding the elements and ensuring long-lasting performance in outdoor environments. The flat bar shape provides a sturdy and stable foundation for hanging or mounting various types of signage or displays. Additionally, steel can be easily customized and manipulated to fit specific design requirements, allowing for endless creative possibilities in outdoor advertising and branding. Overall, steel flat bars are a reliable and versatile choice for outdoor signage or displays, ensuring durability, strength, and visual impact.

- Q: What are the common methods of cutting steel flat bars?

- There are various techniques commonly employed for the cutting of steel flat bars. 1. Manual cutting entails the utilization of hand tools like hacksaws or bolt cutters to slice through the steel. Although it is a slower and more labor-intensive process, it is suitable for small-scale projects or situations where access to power tools is limited. 2. Abrasive cutting involves the use of abrasive wheels or discs to grind through the steel. This method is typically executed with a handheld angle grinder or a stationary abrasive saw. While abrasive cutting is relatively rapid and efficient, it may yield a rougher edge that necessitates further finishing. 3. Band saw cutting is frequently employed, utilizing band saws equipped with metal-cutting blades. This technique enables more precise and accurate cuts, especially for larger or thicker bars. Band saws are available in various sizes, including portable options for on-site cutting or larger industrial models for heavy-duty cutting. 4. Plasma cutting employs a high-velocity jet of ionized gas, known as plasma, to melt through the steel. This method is renowned for its speed and versatility, allowing for the cutting of different thicknesses of steel and the production of clean and precise cuts. Plasma cutting machines are commonly utilized in industrial settings. 5. Laser cutting involves the use of a high-powered laser beam to melt and vaporize the steel, resulting in a precise and smooth cut. This technique is highly accurate and capable of producing intricate designs or patterns. However, laser cutting machines can be costly and are typically utilized in specialized fabrication shops or manufacturing facilities. When selecting the appropriate method for cutting steel flat bars, it is essential to consider factors such as desired cut quality, accuracy, speed, and available resources.

- Q: Are steel flat bars suitable for marine applications?

- Yes, steel flat bars are suitable for marine applications. They are widely used in marine construction due to their high strength, durability, and corrosion resistance. The steel is typically treated to prevent rusting and withstand the harsh marine environment, making it a reliable choice for various marine applications such as shipbuilding, offshore platforms, and marine equipment.

- Q: How do you store and transport steel flat bars safely?

- To store and transport steel flat bars safely, there are several key steps to follow: 1. Proper stacking: When storing steel flat bars, it is important to stack them properly to prevent any damage. Ensure that the bars are stacked horizontally and evenly, with each layer aligned. The weight should be distributed evenly across the stack to maintain structural integrity. 2. Adequate support: Use sturdy supports such as appropriately sized pallets or racks to prevent any sagging or bending of the bars. Make sure that the supports are capable of handling the weight and size of the steel flat bars. 3. Securing the stack: To prevent the bars from shifting during transportation, it is necessary to secure the stack using straps or bands. These should be tightly fastened around the stack, ensuring that the bars are secure and won't move during transit. 4. Protective measures: Steel flat bars are susceptible to corrosion, especially when exposed to moisture. Therefore, it is crucial to protect them from environmental elements during storage and transportation. Consider using protective covers or wrapping the bars in moisture-resistant materials to prevent rust or damage. 5. Proper lifting and handling: When moving steel flat bars, it is important to use appropriate lifting equipment, such as forklifts or cranes, to avoid any injuries or accidents. Ensure that the lifting equipment is capable of handling the weight of the bars and that operators are well-trained in safe lifting practices. 6. Special considerations for long-distance transportation: If transporting steel flat bars over long distances, it may be necessary to use specialized shipping containers or trucks that are equipped to handle heavy loads and provide adequate protection from external elements. Overall, the key to safe storage and transportation of steel flat bars lies in proper stacking, adequate support, securing the stack, protective measures, and employing the right lifting and handling techniques. Adhering to these guidelines will help minimize the risk of damage, accidents, and corrosion, ensuring the safe delivery of steel flat bars to their destination.

- Q: What are the different heat treatment processes for steel flat bars?

- There are several heat treatment processes that can be applied to steel flat bars to enhance their mechanical properties and improve their overall performance. Some of the commonly used heat treatment processes for steel flat bars include: 1. Annealing: This process involves heating the steel flat bar to a specific temperature and then slowly cooling it to room temperature. Annealing helps to relieve internal stresses, increase ductility, and improve machinability. 2. Normalizing: This heat treatment process involves heating the steel flat bar to a temperature above its critical range and then allowing it to cool in air. Normalizing helps to refine the grain structure, improve mechanical properties, and enhance the overall toughness of the steel. 3. Quenching and tempering: This two-step process involves rapid cooling, or quenching, the steel flat bar in a liquid medium, such as oil or water, to achieve high hardness. This is followed by tempering, which involves reheating the quenched steel to a lower temperature to reduce brittleness and improve toughness. 4. Case hardening: Also known as carburizing, this process involves adding carbon to the surface of the steel flat bar by heating it in a carbon-rich environment. Case hardening creates a hard outer layer while maintaining a softer and more ductile core, enhancing wear resistance and providing a tough surface. 5. Stress relieving: This heat treatment process is used to reduce residual stresses in the steel flat bar that may have accumulated during manufacturing or other processes. It involves heating the steel to a specific temperature and allowing it to cool slowly. Stress relieving helps to minimize distortion and improve dimensional stability. These heat treatment processes can be tailored to meet specific requirements and desired mechanical properties of the steel flat bars, making them suitable for a wide range of applications in various industries.

- Q: Can steel flat bars be used for manufacturing appliances?

- Certainly! Steel flat bars are suitable for the production of appliances. Steel, known for its versatility and durability, is frequently utilized in appliance manufacturing because of its strength and ability to resist corrosion. There are numerous uses for steel flat bars in appliance production, including forming the structure, offering support, and constructing brackets and frames. The flat shape of these bars enables effortless fabrication and shaping, rendering them appropriate for a variety of appliance designs. Moreover, steel flat bars can be conveniently welded or joined together, making them an advantageous option for appliance manufacturing.

- Q: Are steel flat bars resistant to impact or vibration?

- Known for their high strength and durability, steel flat bars exhibit a remarkable resistance to both impact and vibration. This is attributed to the composition of steel and its structural integrity, allowing it to effectively absorb and distribute energy resulting from impacts or vibrations. Consequently, steel flat bars are highly suitable for a wide range of applications in construction, automotive, and industrial sectors where resistance to impact or vibration is of utmost importance. Moreover, the ability of steel to withstand impacts and vibrations ensures the prolonged lifespan of structures and components, mitigating the potential risks of damage or failure.

- Q: What are the common methods of joining steel flat bars together?

- The common methods of joining steel flat bars together include welding, bolting, riveting, and using adhesive bonding.

- Q: What are the standard tolerances for width and thickness in steel flat bars?

- The width and thickness of steel flat bars can have varying standard tolerances depending on the specific industry or application requirements. However, there are generally accepted tolerances that are commonly used. In terms of width, the standard tolerances typically fall within the range of +/- 0.005 to 0.030 inches, or +/- 0.13 to 0.76 millimeters. These tolerances ensure that the width of the steel flat bar remains within a specified range, promoting consistency in manufacturing and ensuring that the final product meets the necessary dimensions. Concerning thickness, the standard tolerances for steel flat bars also depend on the specific application. However, a typical tolerance range for thickness is usually between +/- 0.010 to 0.060 inches, or +/- 0.25 to 1.52 millimeters. These tolerances guarantee that the thickness of the steel flat bar remains within a specified range, fostering uniformity in production and ensuring compliance with the required thickness requirements. It is important to acknowledge that these tolerances are generalized and may differ depending on the specific industry or application. It is always recommended to refer to the relevant industry standards or specifications to determine the precise tolerances necessary for a particular steel flat bar application.

- Q: Can steel flat bars be used for fencing or railing?

- Yes, steel flat bars can be used for fencing or railing. Steel flat bars are commonly used in construction applications due to their strength and durability. They are often used as pickets for fences or as balusters for railings. The flat shape of the bars allows for easy installation and creates a sleek and modern look. Additionally, steel flat bars can be easily customized to match the desired design and can be painted or coated to prevent rust and corrosion. Overall, steel flat bars are a suitable choice for fencing or railing projects due to their sturdiness and versatility.

Send your message to us

black galvanized steel flat bar hot rolled steel flat bar vertical flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords