Hot Rolled Flat Steel with High Quality for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Hot Rolled Flat Steel with High Quality for Sale:

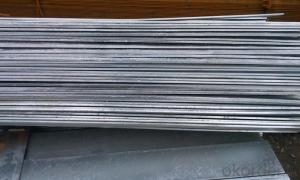

Commodity: Hot Rolled Steel Flat Bar

Standard: GB;JIS

Material: Q195-Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 | B | 235 | 225 | 215 | 205 | 375--500 | 26 | 25 | 24 | 23 |

Usage/Applications of Hot Rolled Flat Steel with High Quality for Sale:

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Hot Rolled Flat Steel with High Quality for Sale:

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Hot Rolled Flat Steel with High Quality for Sale:

1.Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

2.Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer requests.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays

Images:

- Q: Can steel flat bars be polished or buffed?

- Yes, steel flat bars can be polished or buffed. Polishing or buffing is a process that involves using abrasive materials to remove any imperfections or scratches on the surface of the steel. This process can help to enhance the appearance of the steel flat bars by giving them a smooth and shiny finish. Additionally, polishing or buffing can also help to improve the corrosion resistance of the steel by removing any contaminants or oxidation on the surface.

- Q: Can steel flat bars be welded?

- Yes, steel flat bars can be welded. Welding is a common and widely used method for joining or repairing steel materials, including flat bars. The process involves heating the steel to its melting point and then fusing the two pieces together using a welding electrode or filler material. The resulting weld creates a strong and durable bond, making it suitable for various applications in construction, manufacturing, and other industries where steel flat bars are commonly used. However, it is important to follow proper welding procedures and techniques to ensure a successful and structurally sound weld.

- Q: The function of ground lead out galvanized flat steel

- Use and test, debug, you must use lead line.In accordance with the D501 specification, its cross section is not less than 4*40

- Q: Can steel flat bars be used in electrical applications?

- Indeed, steel flat bars have the capability to serve in electrical applications. Given its high conductivity, steel effectively facilitates the flow of electrical current. In the realm of electrical systems, flat bars composed of steel are frequently employed as grounding conductors, busbars, and connectors. These components find widespread usage in switchgear, panel boards, control panels, and various other electrical apparatus. Nevertheless, it is crucial to verify that the steel flat bars utilized in electrical applications satisfy the required electrical and safety standards to avert any conceivable hazards.

- Q: Can steel flat bars be used for making signage?

- Indeed, signage can be crafted from steel flat bars. Steel, being a resilient and adaptable material, can be effortlessly manipulated, sliced, and fused to produce an array of signage designs and dimensions. Steel flat bars can serve as the primary framework or foundation of the sign, delivering stability and reinforcement. Furthermore, they can serve as embellishments, imparting a polished and contemporary aesthetic to the signage. Moreover, steel boasts resistance against weathering and corrosion, rendering it ideal for both interior and exterior signage. In summary, steel flat bars present a pragmatic and dependable option for signage fabrication.

- Q: How do you protect steel flat bars from chemical corrosion?

- To protect steel flat bars from chemical corrosion, there are several effective methods that can be employed. 1. Coating: Applying a protective coating is one of the most common methods to prevent chemical corrosion. There are various types of coatings available, such as paint, epoxy, enamel, or polyurethane. These coatings act as a barrier between the steel surface and the corrosive chemicals, preventing direct contact and thus reducing the risk of corrosion. It is important to choose a coating that is specifically designed for chemical resistance and to ensure proper application for maximum effectiveness. 2. Galvanization: Galvanizing steel flat bars involves applying a layer of zinc to the surface. This process creates a protective barrier that shields the steel from corrosive substances. Hot-dip galvanizing is a widely used method where the steel is immersed in molten zinc, allowing a thick and durable coating to form. Galvanized steel flat bars are highly resistant to chemical corrosion and can provide long-lasting protection. 3. Stainless steel: Using stainless steel flat bars that contain a high percentage of chromium and nickel can greatly enhance their resistance to chemical corrosion. The addition of these elements forms a passive layer on the surface that acts as a protective barrier against corrosive chemicals. Stainless steel is particularly suitable for applications where exposure to aggressive chemicals is expected. 4. Proper storage and handling: Ensuring proper storage and handling practices is essential in protecting steel flat bars from chemical corrosion. Storing them in a dry and well-ventilated area, away from corrosive substances, can help prevent direct exposure. Additionally, using protective covers or wrapping the bars in moisture-resistant materials can provide an extra layer of defense. Regular inspection and maintenance are also important to detect any signs of corrosion early. If any damage or deterioration is identified, prompt repairs or replacements should be carried out to maintain the integrity and longevity of the steel flat bars.

- Q: What are the maximum and minimum thicknesses for steel flat bars?

- The maximum and minimum thicknesses for steel flat bars vary depending on the specific grade and type of steel being used. However, in general, the maximum thickness for steel flat bars can range from around 10 mm to 150 mm or even more, depending on the application and manufacturing capabilities. On the other hand, the minimum thickness for steel flat bars can be as thin as 1 mm or even less, again depending on the specific requirements and manufacturing processes. It is important to consult the relevant standards and specifications or consult with a steel supplier or manufacturer to determine the exact maximum and minimum thicknesses for a particular steel flat bar.

- Q: Are steel flat bars available in different surface hardness options?

- Yes, steel flat bars are available in different surface hardness options. The hardness of a steel flat bar's surface is determined by the type of heat treatment it undergoes during the manufacturing process. Heat treatment processes like quenching and tempering can be used to achieve different hardness levels in the surface of the steel. These hardness levels are typically measured on the Rockwell hardness scale, with higher numbers indicating greater hardness. Steel flat bars with different surface hardness options are commonly used in various industries, such as construction, manufacturing, and engineering, where specific hardness requirements are necessary for the intended application.

- Q: What are the different dimensions available in steel flat bars?

- Steel flat bars are available in a variety of dimensions to cater to different applications and requirements. The dimensions of steel flat bars typically include the width, thickness, and length. Width: Steel flat bars can be found in various widths, ranging from narrow sizes of around 1 inch (25mm) to wider sizes that can be up to 12 inches (305mm) or more. The width of the flat bar is important as it determines the amount of surface area available for supporting loads or providing structural stability. Thickness: Steel flat bars are also available in different thicknesses, which can range from thin gauges of about 1/8 inch (3.18mm) to thicker sizes of up to 1 inch (25.4mm) or more. The thickness of the flat bar is crucial as it influences the strength and load-bearing capacity of the steel. Length: Steel flat bars come in various lengths to suit different applications. The length can vary from shorter sizes, such as 6 feet (1.83 meters), to longer lengths that can extend up to 20 feet (6.1 meters) or more. The length of the flat bar is significant as it determines the amount of material available for cutting, shaping, and fitting into specific projects or structures. It is worth noting that the specific dimensions available may vary depending on the manufacturer, supplier, or country of origin. Therefore, it is important to consult the product specifications or contact the supplier directly to ensure availability of the desired dimensions for steel flat bars.

- Q: What is the minimum order quantity for steel flat bars?

- The minimum order quantity for steel flat bars may differ depending on the supplier or manufacturer. Various factors, such as production costs, transportation logistics, and customer demand, typically determine the minimum order quantity. However, it is not unusual to encounter minimum order quantities that range from 1 to 10 metric tons. It is recommended to get in touch with the particular supplier or manufacturer to inquire about their minimum order requirements and negotiate accordingly.

Send your message to us

Hot Rolled Flat Steel with High Quality for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords