AISI 4140 42CrMo4 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

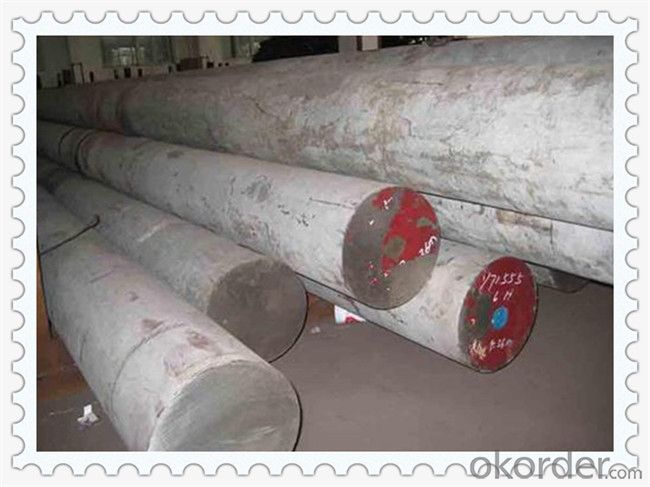

AISI 4140 42CrMo4 Alloy Steel Round Bar

Specifications

1. Delivery condition: Hot-rolled,black surface

2. Chemical composition: C:0.38~0.45 Si:≤0.40 Mn:0.60~0.90 S:≤0.035 P:≤0.035 Cr:0.90~1.20 Ni:≤0.030 Cu:≤0.030 Mo:0.15~0.30

C | Si | Mn | P | S | Cr | Mo |

0.38-0.45 | ≤0.4 | 0.6-0.9 | ≤0.035 | ≤0.030 | 0.9-1.2 | 0.15-0.30 |

3.Process: EAF + LF + VD + Forged + Heat Treatment (optional)

4.Delivery condition: Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

5.Technical Data: According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

6.Test: ultrasonic test according to SEP 1921-84 3 D/D

7. Material details will be as per agreed technical specifications

Equipment

We are well-equipped with 2000-Ton Hydraulic press, 15-Ton Hydraulic manipulator, various kinds of Lathe and boring machine, product range OD 200mm-800mm, Length less than 9m.

Products

- Q: How do you calculate the weight of a steel round bar based on its volume and density?

- To calculate the weight of a steel round bar based on its volume and density, you can use the formula: weight = volume x density.

- Q: Can steel round bars be customized or fabricated?

- Yes, steel round bars can be customized or fabricated according to specific requirements. This can involve cutting, bending, drilling, welding, or other processes to achieve the desired shape, size, or design.

- Q: What are the advantages of using wear-resistant steel round bars?

- There are several advantages of using wear-resistant steel round bars: 1. Enhanced durability: Wear-resistant steel round bars are specifically designed to withstand high levels of abrasion and wear. They have a high hardness level and are resistant to surface damage caused by friction, impact, or scraping. This results in a longer lifespan of the round bars, reducing the need for frequent replacements. 2. Increased strength: Wear-resistant steel round bars possess exceptional strength properties, allowing them to withstand heavy loads and extreme conditions. This makes them suitable for a wide range of applications, such as in industries like mining, construction, manufacturing, and transportation, where strength and resilience are crucial. 3. Improved safety: The use of wear-resistant steel round bars ensures a safer working environment. Their high resistance to wear minimizes the risk of accidents and injuries caused by equipment failures or structural damage. This is particularly important in industries where heavy machinery, tools, or structures are involved. 4. Cost-effectiveness: Although wear-resistant steel round bars may have a higher initial cost compared to regular steel bars, their extended lifespan and reduced maintenance requirements make them a cost-effective choice in the long run. The reduced need for replacements and repairs leads to lower downtime, increased productivity, and ultimately, decreased operational costs. 5. Versatility: Wear-resistant steel round bars can be used in a variety of applications due to their versatility. They can be easily machined, welded, or formed into different shapes and sizes to meet specific requirements. This flexibility allows for their use in various industries and applications, making them an ideal choice for many projects. In summary, the advantages of using wear-resistant steel round bars include enhanced durability, increased strength, improved safety, cost-effectiveness, and versatility. These properties make them a reliable and efficient option for applications where wear and tear are significant concerns.

- Q: Can steel round bars be used in structural applications?

- Yes, steel round bars can be used in structural applications. They are commonly used in construction projects for their strength and durability. Steel round bars provide structural support and reinforcement in various applications such as beams, columns, and braces.

- Q: What are the different methods used for machining steel round bars?

- There are several methods used for machining steel round bars, each with its own advantages and applications. Some of the commonly used methods include: 1. Turning: This is a widely used method that involves rotating the steel round bar against a cutting tool, which removes material and creates the desired shape. Turning is suitable for both external and internal operations and can achieve high precision and surface finish. 2. Milling: In milling, a rotating multi-tooth cutter removes material from the steel round bar to create flat or contoured surfaces. This method is versatile and can be used for various operations, including face milling, slotting, and profiling. 3. Drilling: Drilling involves creating holes in the steel round bar using a rotating drill bit. This method is commonly used for creating holes of different sizes and depths, and can be done manually or through automated processes. 4. Grinding: Grinding is a precision machining method that uses abrasives to remove material from the steel round bar. It is commonly used to achieve a smooth surface finish, tight tolerances, and precise dimensions. Grinding can be performed using various types of grinding machines, such as cylindrical grinders or surface grinders. 5. Boring: Boring is used to enlarge existing holes or create internal cylindrical shapes in the steel round bar. It involves rotating a cutting tool inside the bar to remove material and achieve the desired dimensions and surface finish. 6. Broaching: Broaching is a specialized machining method used to create complex internal or external shapes in the steel round bar. It involves using a broach, a multi-toothed cutting tool, that is pushed or pulled through the bar to remove material and create the desired shape. 7. Sawing: Sawing is a method used to cut the steel round bar into desired lengths or shapes using a rotating blade with teeth. This method is efficient for mass production and can be performed using manual or automated sawing machines. These are just a few of the methods used for machining steel round bars. The choice of method depends on factors such as the desired shape, dimensions, tolerances, and surface finish, as well as the production volume and available equipment.

- Q: Can steel round bars be used as axles or shafts?

- Yes, steel round bars can be used as axles or shafts. Steel is a commonly used material for axles and shafts due to its high strength and durability. Steel round bars are particularly suitable for applications requiring rotational motion, such as axles and shafts, as they can handle heavy loads and withstand bending and torsional forces. Additionally, steel round bars can be machined and heat-treated to meet specific requirements for hardness and surface finish, further enhancing their suitability as axles or shafts. Overall, steel round bars are a reliable and widely used choice for axles and shafts in various industries, including automotive, machinery, and construction.

- Q: Can steel round bars be used in the production of agricultural machinery?

- Yes, steel round bars can be used in the production of agricultural machinery. Steel is a durable and strong material that is commonly used in various industries, including agriculture. Steel round bars can be utilized for manufacturing components such as axles, shafts, and frames, providing stability and strength to agricultural machinery.

- Q: What is the tolerance for diameter in steel round bars?

- The tolerance for diameter in steel round bars may differ based on the manufacturer or industry's specific standards and requirements. Typically, a certain range is specified for the diameter tolerance to maintain the desired precision and consistency in the bars' dimensions. This tolerance is usually denoted as a plus or minus value, indicating the acceptable deviation from the specified diameter. To ascertain the precise tolerance for diameter in steel round bars, it is essential to verify the applicable industry standards or consult with the manufacturer, as it can vary depending on the intended application and manufacturing process employed.

- Q: Are steel round bars available in different lengths?

- Indeed, there is a variety of lengths for steel round bars. These bars are designed in diverse lengths to cater to various needs and applications. The range of lengths may differ depending on the supplier or manufacturer. Typically, steel round bars are commonly available in lengths between 6 and 12 feet. However, it is also possible to acquire custom lengths through special requests. This wide range of options grants more flexibility in construction and fabrication projects, as it facilitates the ability to cut or modify the bars according to specific requirements.

- Q: Are steel round bars suitable for use in the marine industry?

- Yes, steel round bars are suitable for use in the marine industry. Steel is a highly durable and strong material, making it ideal for marine applications where there is exposure to harsh environmental conditions such as saltwater, waves, and corrosion. Steel round bars offer excellent tensile strength and resistance to impact, making them suitable for various marine components like shipbuilding, offshore structures, and marine equipment. Additionally, steel is also readily available, cost-effective, and can be easily fabricated to meet specific requirements, making it a popular choice in the marine industry. However, it is important to select the appropriate grade of steel that has good corrosion resistance, such as stainless steel, to ensure long-term durability and performance in marine environments. Regular maintenance, including proper coating and protection against corrosion, is also crucial to enhance the lifespan of steel round bars in marine applications.

Send your message to us

AISI 4140 42CrMo4 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords