Z26 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

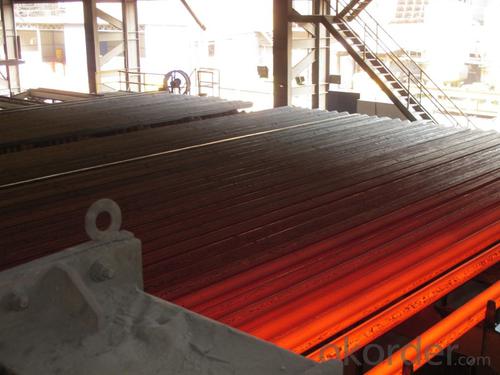

Structure of Z26 BMP Rolled Steel Coil Construction Roofing Construction

Description of Z26 BMP Rolled Steel Coil Construction Roofing Construction

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Z26 BMP Rolled Steel Coil Construction Roofing Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Z26 BMP Rolled Steel Coil Construction Roofing Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Z26 BMP Rolled Steel Coil Construction Roofing Construction

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Z26 BMP Rolled Steel Coil Construction Roofing Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: What are the main factors that determine the demand for steel billets in different industries?

- The main factors that determine the demand for steel billets in different industries are the overall economic conditions, including GDP growth and industrial production, as well as the specific needs and requirements of each industry. Other factors include the level of infrastructure development, population growth, urbanization, and construction activities. Additionally, factors such as technological advancements, environmental regulations, and government policies can also influence the demand for steel billets in different industries.

- Q: What are the specifications for steel billets used in the defense industry?

- The specifications for steel billets used in the defense industry vary depending on the specific application and requirements. However, there are certain common specifications that are generally followed. Firstly, the steel billets used in the defense industry need to have high strength and durability to withstand extreme conditions and potential impacts. They are often required to have a high tensile strength, typically above 500 MPa, and excellent toughness to resist fracture or deformation. Additionally, the steel billets used in the defense industry must possess good corrosion resistance properties. This is crucial to ensure the longevity and reliability of the equipment and structures used in defense applications, especially when exposed to harsh environments or corrosive elements. In terms of dimensional specifications, the steel billets used in the defense industry are typically required to have precise dimensions and tolerances. This is to ensure compatibility and proper fitment during the manufacturing process and assembly of defense equipment. Furthermore, strict quality control measures are implemented for steel billets used in the defense industry. They must adhere to various industry standards and certifications, such as MIL-SPEC (Military Specifications), to guarantee the highest level of quality, performance, and safety. Lastly, depending on the specific application, additional specifications such as heat treatment requirements, chemical composition, and non-destructive testing may also be specified for steel billets used in the defense industry. It is important to note that the exact specifications for steel billets used in the defense industry may vary based on the specific requirements of each defense project, and it is essential to consult the relevant defense industry standards and guidelines for accurate and up-to-date specifications.

- Q: How are steel billets used in the manufacturing of industrial pumps?

- Steel billets are used in the manufacturing of industrial pumps as a starting material for the production of various pump components. These billets are typically made of high-quality steel and serve as the raw material for forging or casting processes. Firstly, steel billets are used in the production of pump casings. The billets are shaped into the desired form, either by forging or casting, to create the outer shell of the pump. This casing provides structural integrity and contains the fluid being pumped. Additionally, steel billets are utilized in the manufacturing of impellers, which are vital components of industrial pumps. Impellers are responsible for generating the necessary force to move the fluid through the pump. The billets are machined, shaped, and polished to form the intricate design of the impeller, ensuring optimal fluid flow and efficiency. Furthermore, steel billets are used for manufacturing shafts and other critical components of the pump. These components require high strength and durability to withstand the demanding conditions of industrial applications. By using steel billets, manufacturers can ensure the necessary mechanical properties are met, such as resistance to corrosion, wear, and high temperatures. In summary, steel billets play a crucial role in the manufacturing of industrial pumps. They serve as the starting material for various pump components, including casings, impellers, shafts, and more. By using high-quality steel billets, manufacturers can produce durable and efficient pumps that meet the demanding requirements of industrial applications.

- Q: How do steel billets contribute to the manufacturing of tools and equipment?

- Tools and equipment manufacturing relies heavily on steel billets, which serve as a crucial component. These semi-finished steel products play a vital role in shaping and forming the final products used across different industries. To begin with, steel billets function as raw materials during the production of various tools and equipment. They act as the starting point for processes like forging, rolling, and extrusion. These processes involve heating and shaping the steel billets to achieve the desired form and dimensions of the tools and equipment. Furthermore, steel billets possess several advantages that make them suitable for tool and equipment manufacturing. The strength and durability of steel make it an ideal material for tools that need to endure heavy loads and harsh conditions. Additionally, the versatility of steel allows for the production of a wide range of tools and equipment, including cutting tools, machine parts, construction equipment, and automotive components. Moreover, steel billets can be easily machined and formed into complex shapes, enabling the production of intricate tools and equipment that meet specific requirements. The excellent machinability of steel allows for precise cutting, drilling, and milling processes, resulting in accurate dimensions and smooth surfaces. Additionally, steel billets can undergo heat treatment to enhance their mechanical properties, such as hardness and toughness. Processes like quenching and tempering can significantly improve the performance and longevity of tools and equipment. When combined with the inherent strength of steel, these processes ensure that the final products have the necessary strength, hardness, and wear resistance to effectively fulfill their intended functions. In conclusion, steel billets are indispensable in the manufacturing of tools and equipment due to their raw material capabilities and advantageous properties. They provide a reliable and versatile starting point for producing various tools and equipment, enabling the creation of durable, precise, and high-performance products that are vital to numerous industries.

- Q: How are steel billets used in the manufacturing of castings?

- Steel billets play a crucial role as a primary material for creating castings. Castings, which are solid metal objects, are produced by pouring molten metal into a mold and allowing it to cool and solidify. The initial step in this process involves heating steel billets until they become molten. Subsequently, the molten steel is poured into a mold, typically made of sand or metal, which is specifically designed to have the desired shape and dimensions of the final casting. The molten steel is then left to cool and solidify within the mold. During this cooling process, the steel adopts the shape of the mold, ultimately forming the desired casting. This cooling phase is of utmost importance as it determines crucial mechanical properties, including strength and hardness, of the end product. Once the steel has solidified, the mold is removed, and the casting undergoes cleaning and finishing stages. This may involve removing any excess material, such as gates or risers, which were used to facilitate the pouring of the molten metal. Additionally, the casting may undergo further processes like machining or heat treatment to achieve the desired final specifications. To summarize, steel billets are utilized in the manufacturing of castings by melting them and pouring the molten steel into a mold to achieve the desired shape. The subsequent cooling and solidification of the molten steel within the mold lead to the formation of a solid casting, which can then undergo additional processing and finishing as needed.

- Q: What are the key properties and characteristics of steel billets?

- Steel billets are semi-finished products that possess several key properties and characteristics. Firstly, they are typically made from carbon or alloy steel, providing them with high strength and durability. They exhibit excellent machinability, allowing for easy shaping and forming during further processing. Steel billets also have a uniform grain structure, ensuring consistent mechanical properties throughout the material. Additionally, they possess a smooth surface finish, making them ideal for subsequent treatments like hot rolling or forging. Lastly, steel billets are resistant to corrosion, which enhances their longevity and suitability for various industrial applications.

- Q: What are the different methods of steel billet surface etching?

- Various industries commonly use several different methods for steel billet surface etching. These methods encompass chemical etching, electrolytic etching, and laser etching. 1. Chemical etching involves the immersion of the steel billet in a chemical solution, typically an acid, that selectively eliminates a thin layer of material from the surface. The specific chemical solution utilized depends on the etching process requirements, such as desired depth and pattern. Hydrochloric acid, nitric acid, and ferric chloride are commonly employed chemicals for steel etching. 2. Electrolytic etching entails passing an electric current through the steel billet while it is submerged in an electrolyte solution. The current facilitates a controlled dissolution of the surface metal, resulting in the desired etched pattern. Electrolytic etching provides precise control over the process and can generate intricate and detailed designs. It is often employed for marking or labeling steel billets with logos, serial numbers, or other identification marks. 3. Laser etching is a highly precise and non-contact method of surface etching. It involves the use of a laser beam to selectively remove material from the steel billet surface. Computer software directs and controls the laser beam, enabling intricate and customizable designs. Laser etching is suitable for creating permanent markings, logos, or patterns on steel billets. It finds wide application in industries such as automotive, aerospace, and electronics. Each method has its own advantages and limitations, and the choice of etching method depends on factors like the desired design, the material properties of the steel billet, and the production requirements.

- Q: What are the different international trade regulations for steel billets?

- The different international trade regulations for steel billets vary from country to country. Some countries may have import quotas or tariffs in place to protect their domestic steel industries, while others may have specific quality or safety standards that steel billets must meet before entering their markets. Additionally, international trade agreements and organizations, such as the World Trade Organization, may also impact the regulations and trade practices surrounding steel billets.

- Q: What are the main factors affecting the corrosion resistance of steel billets?

- The main factors affecting the corrosion resistance of steel billets include the composition of the steel, presence of impurities, environmental conditions (such as humidity and temperature), exposure to corrosive substances, surface finish, and protective coatings.

- Q: How are steel billets used in the production of mining equipment?

- Due to their strength, durability, and versatility, steel billets are crucial for the production of mining equipment. These billets are typically made by pouring molten steel into a mold, resulting in a solid rectangular shape. They are then used as raw material in the manufacturing process of mining equipment. Mining operations require robust and reliable components for equipment such as excavators, bulldozers, and crushers, to withstand harsh conditions and heavy loads. Steel billets provide the necessary structural integrity and toughness, ensuring efficient and safe equipment operation. Once obtained, steel billets undergo various techniques such as forging, machining, and welding to transform them into specific parts and components. Forging can create heavy-duty gears, shafts, and axles, which are essential for mining equipment. Machining steel billets allows for custom-made components that fit seamlessly into mining equipment. This process involves cutting, drilling, and milling to create parts like buckets, cutting edges, and chassis. In addition, welding steel billets together creates complex structures and ensures equipment integrity and strength. This is particularly important in mining equipment construction, where safety and reliability are paramount. In conclusion, steel billets are vital for producing mining equipment as they provide the necessary raw material. Their strength, durability, and versatility allow for the creation of robust and reliable components that can withstand the demanding conditions of mining operations.

Send your message to us

Z26 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords