Billet Steel Producers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Billet Steel Producers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

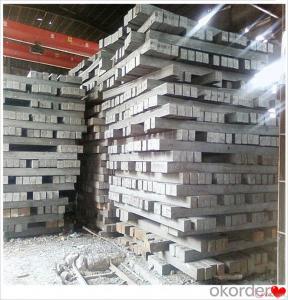

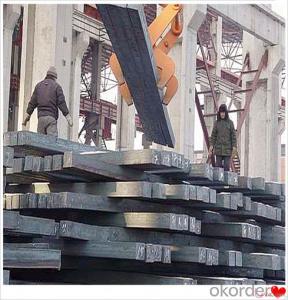

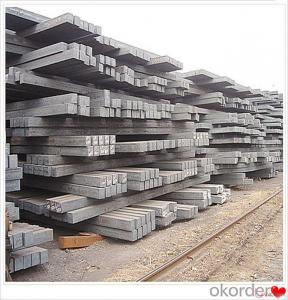

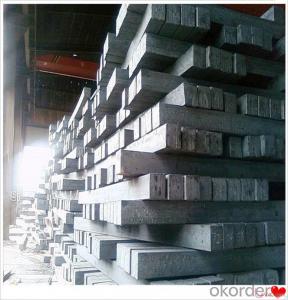

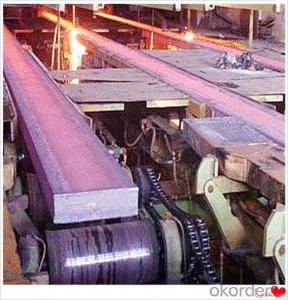

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets used in the production of bearings?

- Steel billets are an integral part of the production process for bearings. Bearings are crucial components that help in reducing friction and enabling smooth rotation between two parts. Steel billets are first heated to high temperatures to make them malleable and easier to work with. Once the billets have reached the desired temperature, they are then shaped into cylindrical or spherical forms using various manufacturing processes such as rolling, forging, or casting. These processes help to achieve the precise dimensions and shapes required for the bearing production. After shaping, the billets undergo further heat treatment processes such as quenching and tempering to enhance their mechanical properties. This heat treatment ensures that the steel has the necessary hardness, strength, and durability required for bearing applications. The shaped and heat-treated billets are then machined to create the raceways, which are the tracks that the balls or rollers of the bearing move along. This machining process involves precision grinding and machining techniques to achieve smooth and accurate raceways. Once the raceways are machined, the billets are further processed to create the other components of the bearing, such as the outer and inner rings, cages, and seals. These components are manufactured separately and then assembled together to create the final bearing. In summary, steel billets are used in the production of bearings as the starting material. Through various manufacturing processes such as shaping, heat treatment, and machining, the billets are transformed into the different components of the bearing, ultimately resulting in a high-quality product that is essential for various industries, including automotive, aerospace, and machinery.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- Steel billets have several potential applications in the agricultural aftermarket. They can be used to fabricate various agricultural machinery and equipment such as plows, harrows, cultivators, and seeders. Additionally, steel billets can be utilized to manufacture durable and sturdy structures like barns, fences, and storage sheds, which are essential in the agricultural industry. The versatility and strength of steel make it an ideal material for these applications, ensuring longevity and reliability in demanding agricultural environments.

- Q: How are steel billets used in the production of steel cables?

- Steel cables require steel billets as a key component for their production. These billets act as the primary material from which the cables are made. The billets undergo a range of processes to manufacture the steel cables. Initially, the steel billets are heated in a furnace to extremely high temperatures, which makes them more pliable and easier to manipulate. This technique is referred to as annealing. Afterward, the billets are passed through a sequence of rollers to shape them into the desired form and size required for the cables. Subsequently, the shaped billets are fed through a wire drawing machine, where they are pulled through a series of dies to decrease their diameter and increase their length. This results in the formation of wire rods that resemble wires. These wire rods then undergo further processing in a series of machines to eliminate any impurities or surface defects. They are subsequently coated with lubricants to minimize friction during subsequent processes. The wire rods are then transferred to a wire stranding machine, where multiple wires are twisted together to form strands. These strands are then combined through either twisting or braiding to create the final steel cables. The cables are once again coated with lubricants to enhance their durability and resistance against corrosion. In summary, steel billets are of utmost importance in the production of steel cables, serving as the initial material for the entire manufacturing process. Through a combination of heating, shaping, and drawing processes, the billets are transformed into wire rods, which are further processed to produce the strands and ultimately the final steel cables.

- Q: What are the different welding techniques used for steel billets?

- Steel billets can be welded using various techniques, depending on the project's specific requirements and desired outcome. Some commonly used techniques include: 1. Shielded Metal Arc Welding (SMAW), also known as stick welding, is a versatile and widely used technique. It involves using a consumable electrode coated in flux, which shields the weld pool from atmospheric contamination. SMAW is suitable for both thick and thin steel billets and can be used in diverse applications. 2. Gas Metal Arc Welding (GMAW), also known as MIG welding, is a popular technique for welding steel billets. It utilizes a continuous wire electrode and a shielding gas to protect the weld pool. GMAW is known for its high productivity and is often employed for welding thin to medium steel billets. 3. Flux-Cored Arc Welding (FCAW) is similar to GMAW but utilizes a tubular electrode filled with flux instead of a solid wire. The flux provides shielding gas and can contain additional alloying elements. FCAW is commonly used for welding thick steel billets and in outdoor or windy environments where shielding gas might be easily blown away. 4. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is a precise and versatile technique frequently used for high-quality welds on steel billets. It relies on a non-consumable tungsten electrode and a separate filler material if required. GTAW produces clean and precise welds but is slower compared to other techniques. 5. Submerged Arc Welding (SAW) involves creating an arc between a continuously fed wire electrode and the steel billet. The arc is shielded by a granular flux, which also provides additional alloying elements and protects the weld pool. SAW is commonly employed for welding thick steel billets, such as in the manufacturing of large structures or pipes. Each of these welding techniques has its advantages and disadvantages. The choice of technique depends on factors such as the steel billet's type and thickness, desired weld quality, productivity, and environmental conditions. Selecting the appropriate technique and following proper training and safety precautions are crucial for achieving successful and durable welds on steel billets.

- Q: How are steel billets used in the manufacturing of mining components?

- Steel billets are a vital raw material used in the production of mining components. These semi-finished steel products act as the initial stage in creating various mining equipment and parts. To begin with, steel billets are heated and then processed through rolling mills to acquire the desired shape, such as bars, rods, or sheets. These specialized forms are then further processed and fabricated to manufacture specific mining components, including pipes, tubes, plates, and beams. Mining components crafted from steel billets offer numerous advantages. The strength, durability, and excellent mechanical properties of steel make it an optimal material for mining equipment exposed to harsh conditions, heavy loads, and extreme temperatures. Steel components can endure the demanding environments found in the mining industry, ensuring their longevity and reliability. Moreover, steel billets can be easily machined, welded, and formed, allowing for the customization of mining components to meet specific requirements. The versatility of steel allows for the production of components with intricate shapes and designs, ensuring their effective performance within mining operations. Furthermore, steel billets can be alloyed with other metals to further enhance their properties. For example, alloying steel with elements like chromium, nickel, or molybdenum can improve corrosion resistance, hardness, and wear resistance, making these components more suitable for mining applications. Overall, steel billets play a crucial role in the manufacturing of mining components by providing a robust and flexible material capable of withstanding the demanding conditions of the mining industry. Their ability to be shaped, customized, and alloyed allows for the production of high-quality and dependable mining equipment and parts that are essential for efficient and safe mining operations.

- Q: How are steel billets inspected for quality control?

- Steel billets are inspected for quality control through a series of rigorous tests and inspections. The process starts with visual inspection, where the billets are examined for any visible defects or irregularities in shape, size, surface finish, or any signs of cracks or inclusions. After the visual inspection, the billets undergo various non-destructive testing techniques such as ultrasonic testing (UT) and magnetic particle inspection (MPI). UT uses high-frequency sound waves to detect any internal flaws or defects in the billets, while MPI uses magnetic fields and iron particles to identify surface cracks or discontinuities. In addition to non-destructive testing, destructive tests are also conducted to assess the mechanical properties of the billets. These tests include tensile testing, where a sample is subjected to tension until it breaks to measure its strength and elongation properties. Hardness testing is performed using various methods like Rockwell or Brinell tests to determine the billet's resistance to indentation or deformation. Chemical analysis is another critical aspect of quality control. Samples are taken from the billets and subjected to spectroscopic analysis to determine the chemical composition, ensuring that it meets the required specifications and standards. Furthermore, dimensional measurements are carried out to verify the billets' accuracy in terms of length, diameter, and other dimensional tolerances. This is done using precision measuring tools such as micrometers and calipers. Overall, a combination of visual inspection, non-destructive testing, destructive testing, chemical analysis, and dimensional measurements is employed to ensure the quality of steel billets. These comprehensive quality control measures help identify any defects or inconsistencies, guaranteeing that the billets meet the required standards and are suitable for further processing in the steel industry.

- Q: What is the size range of steel billets?

- The size of steel billets can vary depending on the industry or application's specific requirements. Square or rectangular shapes are usually used to produce steel billets, with dimensions ranging from 100mm to 200mm in width and height. Additionally, the lengths can range from 3 to 12 meters. These dimensions can be customized according to the intended use of the billets, whether it be for forging, rolling, or further processing into finished steel products.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets play a crucial role in the aerospace industry by serving as the initial material for manufacturing aerospace components. These billets, which are semi-finished steel forms, are either hot-rolled or forged into specific shapes and sizes. Aerospace manufacturers commonly use steel billets to produce critical components like landing gear, engine parts, structural elements, and fasteners. These billets are chosen for their outstanding strength, durability, and resistance to high temperatures and corrosive environments, all of which are vital characteristics for aerospace applications. The production process of aerospace components using steel billets involves several steps. Initially, the billets are heated to a high temperature to make them malleable and easy to work with. Various forming techniques like forging, extrusion, or rolling then shape the billets into the desired forms. These processes guarantee precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, further processes such as heat treatment, machining, and surface finishing are applied to enhance the mechanical properties and surface quality of the aerospace components. Heat treatment methods like quenching and tempering strengthen the steel, improving its hardness, toughness, and resistance to wear and fatigue. Subsequently, machining processes are utilized to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control measures to ensure compliance with the strict standards and regulations of the aerospace industry. Thorough inspections, non-destructive testing, and material analysis are conducted to verify the integrity, performance, and safety of the components. In conclusion, steel billets are indispensable in the production of aerospace components, providing a reliable and robust starting material. The versatility and exceptional mechanical properties of steel make it the preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: What are the different types of mechanical property testing methods for steel billets?

- There are several different types of mechanical property testing methods used to evaluate the quality and strength of steel billets. These methods include: 1. Tensile Testing: Tensile testing is one of the most commonly used methods to determine the mechanical properties of steel billets. It involves applying a tensile force to a small sample of the billet until it fractures. This test measures the strength, yield strength, elongation, and reduction in area of the material. 2. Impact Testing: Impact testing is used to assess the toughness and resistance to fracture of steel billets. It involves striking a notched specimen with a pendulum or hammer and measuring the energy absorbed during fracture. The results provide information about the material's ability to withstand sudden shocks or dynamic loads. 3. Hardness Testing: Hardness testing determines the resistance of the steel billet to indentation or scratching. Various methods can be employed, such as Rockwell, Brinell, or Vickers hardness testing. The results are often correlated with other mechanical properties, such as strength and ductility. 4. Charpy Testing: Charpy testing is a type of impact test specifically designed to evaluate the notch toughness of steel billets. It involves striking a notched specimen with a pendulum, and the energy absorbed during fracture is measured. This test is particularly useful in assessing the material's behavior under low-temperature conditions. 5. Bend Testing: Bend testing is performed to assess the ductility and flexibility of steel billets. It involves bending a sample around a specified radius until it fractures or shows signs of cracking. This test provides information about the material's ability to withstand deformation without breaking. 6. Fatigue Testing: Fatigue testing is used to evaluate the steel billet's resistance to cyclic loading or repeated stress. It involves subjecting a sample to a varying load, and the number of cycles required for failure is recorded. This test helps determine the material's durability and its ability to withstand long-term stress. These mechanical property testing methods play a crucial role in ensuring the quality and reliability of steel billets for various applications. By evaluating the strength, toughness, hardness, and other mechanical properties, manufacturers and engineers can make informed decisions about the suitability of the material for specific uses.

- Q: How do steel billets contribute to the overall safety of a product?

- Steel billets contribute to the overall safety of a product in several ways. Firstly, steel billets are manufactured using a controlled process that ensures a high level of quality and consistency in the material. This means that the steel produced from these billets will have consistent mechanical properties, such as strength and toughness, which are crucial for ensuring the safety of the final product. Additionally, steel billets undergo various testing and inspections during the manufacturing process to ensure that they meet the required specifications and standards. This includes checks for surface defects, internal soundness, and proper chemical composition. By ensuring that the steel billets are defect-free and meet the necessary quality standards, the risk of failure or malfunction in the final product is significantly reduced. Furthermore, steel billets are known for their exceptional strength and durability. Steel is a highly robust material that can withstand high temperatures, pressure, and impacts without deforming or breaking. This inherent strength makes steel billets particularly suitable for applications where safety is a priority, such as in the construction of buildings, bridges, and infrastructure. Moreover, steel billets can be easily shaped and formed into various components and structures, allowing for precise manufacturing and design. This versatility enables engineers and designers to create products with optimal safety features, such as reinforced beams or structures that can withstand extreme loads or impacts. The ability to customize steel billets to meet specific safety requirements ensures that the final product is tailored to address potential safety risks and hazards. Lastly, steel billets are highly resistant to corrosion, making them ideal for applications in harsh environments or exposure to corrosive substances. The resistance to corrosion ensures that the structural integrity of the product is maintained over time, reducing the likelihood of failures due to material degradation. In conclusion, steel billets contribute to the overall safety of a product by providing a high-quality, defect-free, strong, and durable material that can be customized to meet specific safety requirements. The controlled manufacturing process, rigorous testing, and inherent properties of steel make it an ideal choice for ensuring the safety and reliability of various products.

Send your message to us

Billet Steel Producers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords