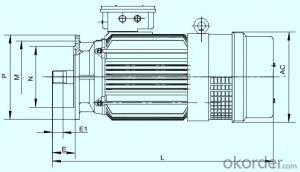

YTLEJ(IPW23)Torque Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview

This series motor adopts modular design. It consists of four parts: torque motor, eddy current regulator, electromagnetic brake and fan, which can be flexibly configured to

meet different customer demands. With introduction of a new special brake, it can cater for outdoor and high-altitude operations. The product has reached the international

advanced level with the patent for utility model. It is mainly used as a trolley speed-change gear for tower crane as well as other mechanical equipments requiring for

constant power and stepless speed regulation.

FeaturesConstant tension and linear speed, stepless speed regulation, frequent starting;

Special eddy current regulator for the motor realizes smooth startup or stop;

New special brake (national utility model ZL201120188173.2, ZL2011201881643). This ensures fast braking and accurate positioning with higher safety and reliability

Besides, manual release is possible;

The rotor is made of copper alloy with better mechanical properties and mechanical bearing capacity in the domestic industry;

Spindle is hot forged by alloy structural steel,with good overall mechanical perlormancc;

A thermal protection component is buried into the in stator winding, making motor more safer and reliable;

Compact structure, small volume, lightweight as well as high reliability, so itfeatures easy maintenance and repair.

- Q: What's the difference between direct current motor and AC motor?

- Alternating current motors are divided into stator windings and rotor conductors. The rotor conductor is shaped like a silicon steel sheet between a cage and a conductor. Some of the AC motors also have windings

- Q: I have a 1.5hp 220v 3 phase motor driven band saw. I need to run it on a 220v single phase system. The original single phase converter consisted of a 550uF capacitor supplying the third phase winding with the contacts of an NC relay in series with the capacitor. The coil of the relay is from the supply through a resistor to the third phase winding and dropped out when the motor came up to speed. A second 40uF capacitor is from the supply to the third phase winding and is the only capacitor that remains active when the relay opens up (motor is up to speed). I'm looking for a simpler and more reliable solution, as the present circuit is temper mental and old. Replacing the motor is a last resort. Is there a simpler capacitor type converter that can be designed? The saw is only operated intermittently for 10-15 minutes on time, 30-60 minutes off for an 8 +hour period, for a few days a month. It is used for a meat cutting band saw. Any sources, help or information would be greatly appreciated. Thank you.

- Capacitor type converters do tend to be temperamental, but the circuit you have seems to be about as simple as they come. Rotary phase converters are generally considered much better, but are also much more expensive. Another option that may be practical due to the lowering cost of semiconductors, is a is a VFD inverter drive, while the name includes variable frequency you can just as well use it at a fixed speed. Just a couple weeks ago I installed 3 conveyors with singe phase to three phase VDF inverters (albeit wit smaller motor than yours) and they work flawlessly.

- Q: after pulling blower motor from furness, thinking the brushes are bad can they be replaced or do I need to buy?

- Exactly! AC motors like that don't have brushes. Although some AC motors do. Like a power tool that uses 120 volts. Those kind run on AC or DC.

- Q: I want to use the motor from an old lawn edger, which has to be plugged into a wall to work, for a small battery powered skateboard for my son being powered by a car battery. Is this possible without havng to buy a hundred dollar power convertor...can I splice the wires and hook them up directly to a car battery?

- You need to check the voltage of the motor first. If it has an input voltage of 50v then 12 volts may not be enough. and although it may spin, it would not have the power to spin under load. I would also imagine that the motor would have to be geared in some way. If you were going to go down that road then I would suggest using a starter motor from a car or something similar.

- Q: Can anyone give me the torque equations for AC synchronous motor and generator

- Torque=Kt*I, where Kt is the torque constant and I is the current. It's that simple.

- Q: How to use single-chip microcomputer to control AC motor 65KTYZ, what should be used to control the chip? Please give expert advice. It is better to give access to each interface.

- This motor is single-phase or three-phase, ah, second power, how big, these need to know.If it is a small single-phase or three-phase motor, AC motor can be controlled by solid-state relay or by small AC contactor control relay, if it is large, it is best to use the second scheme just said. It is so simple. What if there are special requirements that is another, I can talk.

- Q: well its a 2.5L Somerset, and when i got it the ac would only blow on the 3rd setting but when i would put it on High the blower motor would stop but ac compressor still on. well now it completely gave out! no settings will work so it wont blow at all.What wrong? its to hot!

- Have a stable mechanic examine it out because it may basically be something minor. although in case you ought to pay for it you nevertheless have been given the vehicle for unfastened so which you will no longer have plenty invested. you probably did thank your Grandfather did no longer you?

- Q: Why is AC motor control more difficult than DC?

- Motor control, generally refers to speed regulation".AC motors are different from the mechanical characteristics of direct current motors,The mechanical characteristics of the DC motor are 1 slightly downward inclined "straight lines", the relationship between its speed and torque (characteristic) is relatively "hard", and it can easily change its speed by changing the power supply voltage of the motor;

- Q: how can increase the speed of an ac motor?

- The okorder /

- Q: I need to know for an economic calculation how much would it cost to uninstall a 15hp ac motor (old) and to install a new one that is attached to a industrial air compressor...please...just an estimate...

- Should okorder /

Send your message to us

YTLEJ(IPW23)Torque Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches