YTLVF(E)180 Frequency-changing three-phase asynchronous motor for tower crane.

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GENERAL

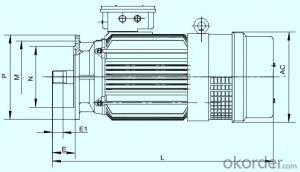

This motor is improved and developed on the base of the operation conditions of tower

crane and adopting the foreign advantage of special motors. The primary motor is

frequency-conversion dedicated motor. The thermvsensative elements are embedded

in the windingsSpeed sensor and brake can be set as requested by various users

APPLICABLESCOPE

This motor is mainly used for the lifting mechanism of tower crane and also for the lany mechanism of large-sized crans

Model:

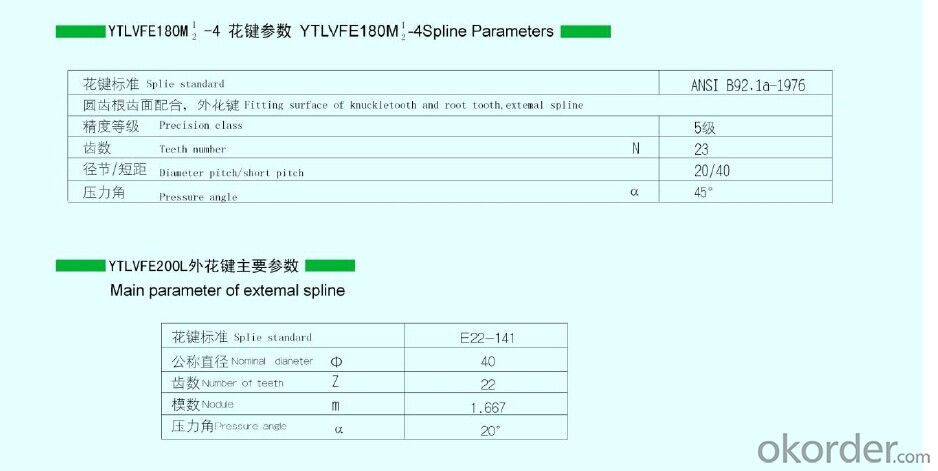

YTLVFE180M1-4 18.5KW

YTLVFE180M2-4 24KW

YTLVFE200L-4 30KW

and any other Power.

- Q: Is the single-phase carbon brush motor a direct current motor or an AC motor?

- The role of the motor is to change the current direction of the DC motor and AC motor, the DC motor is to change the rotor's conductive coil, thereby changing the rotor magnetic pole. Thereby changing the motion of the motor. The carbon brush is used for motor commutator or slip ring, as sliding contact body import and export current, its thermal conductivity, and good lubrication performance, and has certain mechanical strength and direction of the spark of instinct. Almost all motors use carbon brush, which is an important component of the motor.

- Q: DC Supply will given to a AC Motor?

- The current will be = Vdc / DC resistance, as there is no back emf.The motor will not rotate.

- Q: grounded motor last year and worked.grounded this year worked 3 days

- Take your car in to have it looked at. There could be a problem with one of four things. A. Blower motor. B. Blower motor resistor. C. HVAC controls. or D. Electrical wiring.

- Q: I just took an Ac electric motor from an old broken washing machine and I would like to use it for a project but I dont know how to wire it to make it work. Im trying to build a machine to roast pigs over a fire but i need help because i dont know how to set up the motor. if some one can explainto me how it works, it would be very helpfull. There are two white wires going to the top and three others, black blue and red, going to the coils. On the motor, it says its a 110v Ac - EL (CL F) 16000 rpm 50/60HzIf some one could help me or show me where i can learn all i need to know, it would be very helpfull.

- good luck with roasting pigs at 16000 rpm(you must mean 1600 for a washing machine), it's a multi speed motor with reverse and needs a capacitor to start so you will need a wiring diagram unless you can work out what the wires on the washing machine did

- Q: Three speed motor. How do you switch fan speeds from heat to ac to see if the motor has a bad motor spot.?

- I'm not sure what you mean by a bad motor spot. You can normally check this by switching the Auto/On fan switch while the unit is running in the heating mode. You should be able to hear the fan speed change while doing this. Normally your fan is set to low speed for heating and high speed for cooling but this is not always the case. Many times the installer will set the unit to run in high speed all the time. Good luck!

- Q: does a 3 phase ac electric motor used as a generator create 3 phase ac power?

- No, only if you provide a source of 3 phase power to energize the field windings. Without that, you just have a few coils of wire spinning near other coils of wire. No magnetic fields, no power generated.

- Q: I need some websites that show how a weed weaker motor works.

- I'm assuming you mean a weed wacker, in which case there are two different motors to be considered. The first would be an electric, usually AC, motor. These motors work as expected, several coils of wires and magnets. Current flows through the wires inducing a magnetic field, the magnetic field interacts with the magnets and the motor turns. The other type is gasoline driven. Because these machines are relatively small and handheld they typically use a two stroke engine. There is a link to a document below that should give you an understanding of how the two stroke motor works.

- Q: 4.5 amp 120 VAC 60hz MOTOR SPEED CONTROL SWITCH? help!?

- Most AC motors are not suitable for simple speed controls. Generally, you should contact a motor manufacturer's tech support to see which (if any) speed controls are suitable for a particular motor. Split phase motors are unlikely to start at a low speed setting and will burn out.

- Q: i have 230v 750w ac motor , can it run in 100AH dc battery?

- You cant use an AC motor with a DC power source. you will need to have an inverter to change the DC to AC and a 100ah battery is like the one I might find in a computer where you would probably need a 4000ah battery to make it worth wild

- Q: how to reduce single phase AC motor speed?

- The only way is reducing the supply frequency .....disregard all the rest !!!!! or u'll burn r motor out !!!

Send your message to us

YTLVF(E)180 Frequency-changing three-phase asynchronous motor for tower crane.

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches