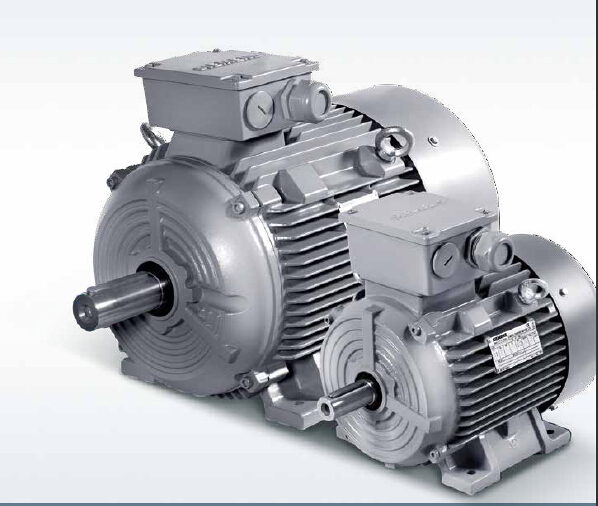

Siemens Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: I've seen on facebook page of some technical institute that Tesla was NOT the first to build the AC motor, do you know who was first then?

- 3 PHASE synchronous motor was made first by Friedrich August Haselwander in 1887. 3 PHASE cage induction motor was built first by Michael Dolivo-Dobrowolsky in 1889

- Q: Is the permanent magnet motor a direct current motor or an AC motor?

- Because AC motors require a changing magnetic field so that the rotor can be rotated in accordance with the frequency of the alternating current, the permanent magnet can not be used in the AC motor.The magnetic field of a direct current motor can be constant, so permanent magnets can be used.

- Q: Regarding electric motors with armatures and commutators and all that. With a split-ring commutator, it switches the direction of the current in a DC motor so that the armature can make full revolutions. So, if you take out the split-ring commutator, does that turn it into AC? And AC, by definition, changes current direction every half-turn, so why wouldn't AC make full revolutions too? Confusing..

- Commutators are necessary if you wish to power a motor with DC, or if you wish for an electric generator to generate DC. Electromechanical machines do not like DC as you can tell, and neither do transformers. If you do not have a commutator and you instead operate a motor from AC with just a simple connection, such a motor is called a synchronous AC motor, such that the rotation rate of the rotor is in tune with the frequency of the AC signal. Asynchronous AC motors are much more difficult to build. This is why 3200 RPM and 7200 RPM are common rotation rates, because they are in tune with US standard household frequency.

- Q: What are DC and AC servo motors? What are the characteristics?

- Into a DC servo motor brush and brushless motor, brushless motor has the advantages of simple structure, low cost, high starting torque, wide speed range, easy control, maintenance, maintenance is convenient but (for brush), will produce electromagnetic interference, the environment requirements. Therefore, it can be used for cost sensitive ordinary industrial and civil occasions. Brushless motors are small in size, light in weight, large in output, fast in response, high in speed, low in inertia, smooth in rotation and stable in torque. It is easy to realize intelligent, and its commutation mode is flexible. It can be changed by square wave commutation or sine wave commutation. The utility model has the advantages of no maintenance, no carbon brush loss, high efficiency, low running temperature, small noise, small electromagnetic radiation, long service life and various environments.

- Q: What is brushless motor, no and brush what is the difference?

- Brushless motor refers to brushless DC motor, which consists of motor, its main body and driver. It is a typical electromechanical integration product.Because of the brushless DC motor is controlled to run, so not like synchronous motor frequency control under heavy start as in the rotor plus a start winding, does not produce oscillation and step mutation in the load. The permanent magnet of small and medium capacity brushless DC motor is now using rare earth neodymium iron boron (Nd-Fe-B) material with high magnetic energy. Therefore, the volume ratio of the rare earth permanent magnet brushless motor reduces a frame number compared with the three-phase asynchronous motor of the same capacity.

- Q: I want to control the speed of a small electric motor. I'm making a small hobby project, what parts would I need to do this, besides the motor? Also should I use a brushless, or regular motor?

- Well its a small motor or else i would have recommened a motor-drive which gives you same amount of tourqe but less RPM. If you lower your voltage it will have less rpm but not as much torque only way to do this is to put a gear box in. or gears

- Q: I need to know what are the specifications that an AC Motor must have on its nameplate...and who says it (ISO,Nema, DIN...)

- The USA standard (motors rated in horsepower) is NEMA MG1 International Electrotechnical Commission (IEC) standard 60034 covers motors rated in kilowatts.

- Q: Can a function generator be used with ac/dc motor to increase or decrease its frequency?

- I doubt it. The only function generators I have come across have very minimal power output.

- Q: Could anyone one please explain how the available torque for an AC motor varies with speed?

- There are many many different types of AC motors so you really need to specify which type of motor you are referring to. However I'll assume the 3-phase squirrel-cage induction motor as this is one of the most commonly used. It has a moderate starting torque (at zero rpm), then the available torque increases as speed increases until just before synchronous speed (= the AC supply frequency) when it reaches the maximum drop-out torque. Torque then drops rapidly to zero at synchronous speed. Beyond synchronous speed the motor can develop negative torque - where it can function as a generator instead of a motor!

- Q: Explain how using a commutator rather than slip rings allows dc rather then ac to be used to drive a motor.

- The commutator changes the armature's winding power connections as it rotates, so that the pole pieces are always energized to the right polarity for the motor to spin. Obligatory wiki link below has a nifty diagram.

Send your message to us

Siemens Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords