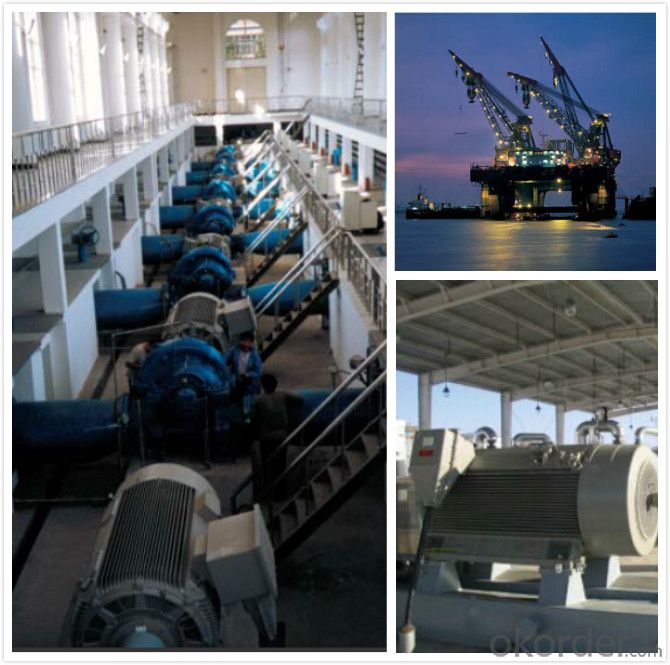

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: How does IGBT works in frequency inverter for ac motor control?

- Igbt Inverter

- Q: o.k I am trying to find porject Ideas, and they sayed you can transfer ac to dc power with this stuff??? and I also have a 18 gauge wire I also have in mind to make this into stuff into a small toy boat can somebody plasese help me~!

- What now? Now you own a power transformer, a dc motor and a bridge rectifier. Since none of the three things you currently own would be compatible with the others, I have absolutely no idea how you would go about making them into a small boy boat.

- Q: I took apart a couple of small motors and found that they all have the copper coils attach to the shaft and spin around stationary magnets, rather then the other way around.The reason I'm asking is because they also have those two copper prongs touching the shaft in order to transfer the electricity back and forth, which wouldn't be necessary if you had the magnets spin and the coils stationary.

- Motors work by having the rotor poles constantly attracted toward the stator poles they are approaching, and repelled from the stator poles they are moving away from. This means either the rotor poles or the stator poles must have alternating magnetic polarity. In a motor designed to run on AC, you could have magnets in the rotor if the stator coils are driven by AC. However this would require that the rotor spin exactly at the AC rate. Instead, AC motors don't use permanent magnets at all, but use the magnetic induction effect, with no commutator necessary, to produce rotating polarity in the rotor that matches that of the alternations of the stator field. For DC, coils are needed in the stator so the rotation of the rotor can be used to switch its own polarity via the coil current reversal provided by the commutator. If you had PMs in the rotor of a DC motor, with only DC in the stator coil there'd be no rotation. I suppose you could design a DC motor with a PM rotor and a commutator that switches the stator polarity. I think you'd need slip rings plus a commutator. That should work and it could be an interesting project.

- Q: Seven month old 230V, 7.5hp, 1 phase motor with start/run capacitors having trouble starting natural gas well compressor. I am pretty sure the load is still the same. Once started the motor runs within specs. Could it be the start capacitor?

- Yes the capacitor could be faulty or the centrifugal switch or a bad winding or connection. The switch being easy to test as it should be made with the motor stopped. The capacitor probably best to check by changing it. You can do a rough check on the windings with an ohm meter but this may not tell you if an internal fault is shorting some of the windings but if its not the switch or capacitor then the thing's probably junk anyway. You think the load is the same but this is a big motor for single phase and compressors are hard to start so you need to be sure. Single phase motors can be a ***** when they don't work so good luck.

- Q: It is an older motor, but runs well... except that it doesn't always start in the same direction. When I switch it on, it hangs for a second and then starts in either one direction or the other.

- The capacitor is frequently linked between a objective terminal and then the two to stay or independent. bypass away one end of the capacitor at its objective terminal, yet substitute the different end from stay to independent (or vice versa).

- Q: The heater/ac blower recently quit working on my '97 Olds Bravada. If you turn the fan speed dial all the way up and then move it from highest setting to setting thats just lower than highest you can hear a clicking sound coming from top of dash, almost like it's below the speaker

- Lift your hood and look on the left side of the firewall. You'll see a plastic drum shaped piece of plastic. It's located right there.

- Q: Here is the question: Some motors must be able to switch directions, sometimes spinning clockwise and other times counter-clockwise. For example, the motor in a VCR must fast forward and rewind videotape. In these situations, explain which type of motor is the best choice. Could someone please help me understand? Everyone is saying it's DC, but I don't understand why.

- A motor of either type has 2 wires. If an a.c. type motor, it matters not which way round you connect the a.c. supply to the motor: it will always spin the same way. A d.c. motor will reverse its direction of rotation if the wires are switched over.

- Q: Whether there is any change if we give ac supply to a dc motor?

- Nah, it'll be fine. Go for it.

- Q: All I want to do is run an AC electric motor off a battery :/

- no that wouldn't work. A tri-state hex inverter is used to make digital 1 into 0 and 0 into 1, and since dc current and voltage has a constant amplitude you would get a constant amplitude. You could just get a power inverter or try building the circuit at this site

- Q: The fan only works on high, it started losing speeds one and three, now only four works

- It is definitely the resistor most are located around the fan motor or ac/heater core.

Send your message to us

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords