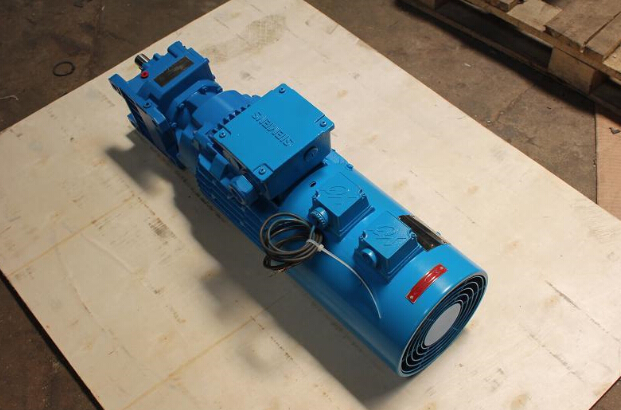

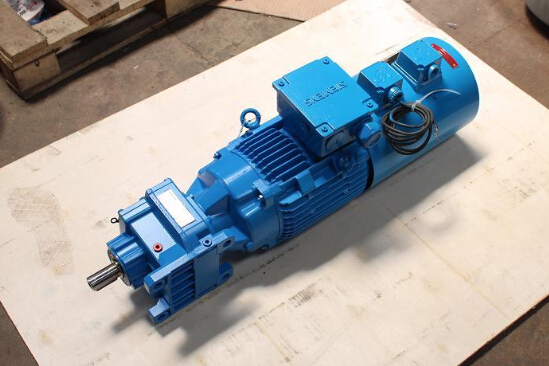

Siemens Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Say i have a 400hp ac 3-phase motor.speed is given as 3575 rpm.Does this mean that if left to run on it's own (with 60hz and the related voltage etc) or unloaded it would produce 3575rpm? and the torque would just be power/speed?if this is the case, does this mean that if i loaded the motor with double this torque its speed would half?Basically i'm trying to figure out how to work out the performance characteristic of a motor for different loads given the basic manufacturers data.thanks...

- No the speed would not be half, the power consumption would rise. You need to review the motor manufactures performance curves to find it's characteristics.

- Q: The 220 window unit's old motor has the same specs as the new one (it was free) EXCEPT the old one was 500MFD 60 HZ; new one is 750MFD 70hz. It is an old Kenmore AC, 1983, but it works great, and would be a real pain to install another unit... GE motors.... It seems to run well on high speed, many hours so far... over time will the motor burn up??

- The 750 MFD @ 70hz and the 500 MFD @ 60 hz are the maximum ratings of the capacitor and not the motor. MFD stands for Microfarads and is a rating of capacitance. If you didn't match the capacitor then the 500 mfd might be a little small. The capacitor could fail. But if it is starting fine then it is likely okay. That is the start capacitor to get it going. It might be too small if the motor gets older and has a little more trouble starting. If the fan capacitor is a separate capacitor you might consider getting a larger one. But I have seen many motors run fine on ones smaller and more is not a problem so the original may have been oversized anyway. And they only operate in the start. But sometimes they use a dual capacitor for the compressor and the fan, one with three or four connectors on it. Changing out, matching, those is more problematic and expensive. I would guess you are okay. Good Luck.

- Q: I noticed that most elevators are powered not by an electric motor, but by an electric motor-generator set. Does the generator really put out enough current to make up for the friction losses?Or is the generator used for powering lights and stuff? If so, why not use inverters or some smaller, cheaper means of creating a smaller current for the lights?

- They use that to change the voltage.

- Q: I have a cheap reciprocating saw that is 120VAC, 60Hz, 4.5A. Says 0-2300 strokes per minute and has a dial speed adjust,k but slowest is still around 300SPM, I need to slow that down more for a custom project I am working on for a hobby idea. How does the speed control built in work? Any way to duplicate that inline with the AC plug? Is there a way to add an inline circuit to slow it down? If you have any ideas, please share and possibly add schematics. I do not want to have to replace the motor or open the case in any way, so an in-line device would work perfectly.

- a hand saw would probably be the cheapest option

- Q: how to select the number of turns, height of the core, size of the copper wire. and tell me hoe to reduce tghe noise in AC unjiversal motor

- Money, money, and money. How much are you willing to spend?

- Q: I have a motor used for the rotating table in a microwave. I'd like to use it to slowly pan my camera at an even speed. The only problem is that now it's out of the microwave

- The microwave must have a transformer to produce the proper voltage. Without that, you could use a 24 volt control transformer that is commonly used in home hydronic heating systems. These are available from any plumbing-heating supplier and will generally output about 25 to 26 volts which is a little high but should be O.K. Connect the transformer primary up to a conventional power cord and plug it in to a wall outlet. If you wish to reduce the voltage, you may be able to get good results by connecting the power to the transformer through a light dimmer, with a volt meter to measure the voltage to the motor.

- Q: I was just wondering what the 3 wire connected to. is there anyway to run that motor without the control system (or the circut board that i cannot remember the name of at the moment) that attaches to the battery.thanks, if you have any diagrams that would get you a best answer!!thanks again

- These motors will not work without the control board. The motor is actually a 3 phase AC motor, the control board provides the battery conversion to 3 phase, and varies the supply frequency for speed control. So each wire is connected to a separate winding in the motor. I don't know whether the windings are connected in a star or delta configuration, though. Maybe either might be used. There are brushless DC motors about, but generally only low power ones. They only have 2 wires. The necessary switching functions usually done by carbon or metal brushes, are done by internal electronics instead. They are common in motors such as computer fans.

- Q: Why does the current in an AC Induction motor start to go up when the voltage is dropped off?

- Because the induction motor is a constant power device. If the voltage goes down, the current goes up to maintain constant power.

- Q: The engine would be for a boat so another question i have is does anyone have any idea how to calculate or figure how many kw it would take to run a dc motor like that obviously it would not be running at 715 hp the whole time because that is only needed for acceleration. Thank you!!!!!!!

- It would likely be that a ship would be powered by multiple electric motors rather than a single motor, but even if the specs called for a single motor, yes electric can be made that powerful.

- Q: Why is AC current so widely used. Are there any specific things that make it better than dc? In regards to power lines, voltage levels, temperature and stuff I dunnothanks

- Power is always generated as AC. Conversion to DC requires more equipment and will also experience losses in the conversion . AC works really for motors because you don't need brushes, so they more efficient. AC is also safer than the same voltage DC because DC will tend to grab you and not let you go but AC tends to throw you since it passes through 0 volts every cycle. High voltage DC can actually be transmitted more efficiently than AC but in order to justify converting it you need to be transmitting it along very large length of power lines. Oh and of course anytime you want to change the voltage you need to go back to AC, because that's what a transformer needs. That's probably one of the biggest reasons actually. I should credit Midatlantian for reminding me.

Send your message to us

Siemens Reducer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords