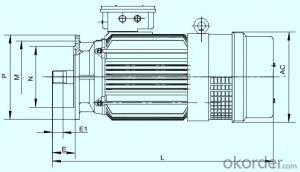

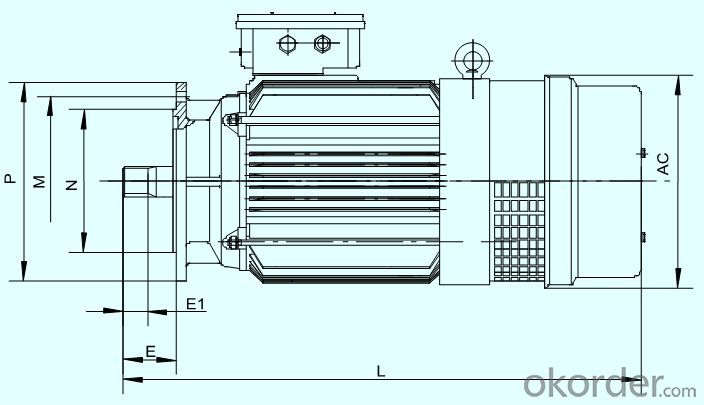

YTDVF Variable一Frequency Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview

the motor is a variable-frequency, three-phase asynchronous motor exclusively designed for the tower cranes and other similar amplitude mechanisms. It is applied to the

amplitude mechanisms in very harsh working conditions such as construction site or open pit quarry

Features

With introduction of spline output shat, it has good mechanical bearing capacity and excellent assembly performance;

Motor installation interface has the same size with original tower crane (POITAIN series), making it easier for switching and upgrading of old products

The motor is a variable-frequency motor featuring a wide range of speed regulation, small starting current, big starting torque and overload ability;

A thermal protection component is buried into the in stator winding and wired into the motor temperature protection control system, making motor more safer and reliable;

New brake (national utility model ZL201101881732, ZL201120188164.3) with higher safety and reliability this reduces the maintenance time and cost compact structure, small volume, lightweight as well as high reliability, so it can be braked quickly and positioned accurately. It is suitable for frequent starting and raking

- Q: its an ac motor, but it spins the wrong way, i need to reverse it.

- It is a shaded pole motor and it is not electrically reversible, but, it may be possible to remove the rotor (loosen the two screws holding the bearings in place) and reassemble it with the output shaft on the other side of the frame which will result in the shaft rotating the opposite direction

- Q: When an AC motor overheats badly, what is generally the first point or two that it will fail at? And what will be required to remedy the problem?(I see alot of carbonization of the coils in various places.)'m working on bringing an old single phase 120 V, 12 A motor back into operation but I'm a bit new to motor theory and many other things under the sun.I pulled the motor off the table saw it came from, cleaned it up, realigned the extremely misaligned rotor with the stator so it turns easily again BUT it still isn't working, it just sits there and hums it's terrible hum. So obviously the alignment is not the current cause of the motors inability to operate.Thanks for your help!

- By the sound of things (The Humming noise) your rotor windings have a short circuit. They can be tested on a machine that is an electro magnet. Most auto electricians should have one. (Especially the old guys). I can remember the name of the machine sorry. Takes all of 2 minutes.

- Q: It is possible AC motor run on DC supply.What can i do to run a AC motor on DC Supply

- Cannot run directly on DC supply or motor burns into smoke within a few seconds. Only one way to run it... DC ---> DC to AC converter -----> AC motor

- Q: My dad owns this car and the AC recently went out and he does not have accessibility to information regarding how to replace the blower motor. Has anyone done this, or do you have access to detailed instructions from Chilton's, etc.? I tried to look online, but I came up empty-handed. My dad used to own an auto repair shop, so do not worry about your response being too detailed or technical. Any assistance would be greatly appreciated. Thank you in advance.

- oh shoot, according to the previous answerer, it's under the hood on the firewall. that's a pain in the butt to change. here's a time saving tip that will prevent unneccessary curse words and random wrenches through the windshield of the vehicle beside yours: remove the cradle bolts that attach the lower subframe to the body. either 15mm or 18mm but have a jack under it so it doesn't fall too far. this will lower the engine assembly enough to remove the blower motor. next, use a strap or ratcheting tow strap to pull the engine forward AFTER REMOVING THE ENGINE MOUNTS in front of the engine. this will pull the motor forward and the jack can lower it. after these two steps, the blower motor is gravy. without these steps, you will be bleeding and cursing, guaranteed, i've been there!

- Q: i need the starting torque and speed (rpm) of the following motors:Shaded PoleReluctance StartSplit Phase (Standard)Split Phase (Capacitor Start)Split Phase (Permanent Split Capacitor)Split Phase (Two Value Capacitor)Universal / SeriesRepulsion (Repulsion Start)Repulsion (Repulsion-Induction)Synchronous (Reluctance)Synchronous (Subsynchronous Reluctance)Synchronous (Hysteresis)Eddy CurrentInduction (Squirrel-cage)Induction (Wound-rotor)Commutator (Schrage)Commutator (Fynn-Weichsel)3? Synchronous (Permanent Magnet)3? Synchronous (Synchronous Reluctance)3? Synchronous (Hysteresis)3? Synchronous (Synchronous Induction)Stepper (Permanent Magnet)Stepper (Variable Reluctance)Switched Reluctance MotorCapacitor MotorRepulsion

- Not interested in auto synchronous then?

- Q: A 16 pole synchronous motor runs at a speed of 450rev/min Determine:A) The supply frequencyB) The speed at which it would run if it operated at a frequency of 55Hz

- A) The frequency times 60 = rpm times number of pole pairs. therefore the frequency = (450 X 8)/60 = 60hz Note pole pairs used not poles and frequency is times 60 to convert to revs per second B) (55 X 60)/8 = rpm 412.5

- Q: what is induction motor?

- Induction Motor Definition

- Q: what is the hp of the largest electric motor.?

- NASA okorder /

- Q: I want to use the motor from an old lawn edger, which has to be plugged into a wall to work, for a small battery powered skateboard for my son being powered by a car battery. Is this possible without havng to buy a hundred dollar power convertor...can I splice the wires and hook them up directly to a car battery?

- IF it's an AC motor - it won't work on DC (battery voltage).

- Q: Their advantages,disadvantages comparison table?

- These are terms used in vfd's except FOC, I've no idea what that means. The other terms are not comparable anyway. Try looking at manuals for various manufacturer's vfd's such as ABB, Toshiba, etc

Send your message to us

YTDVF Variable一Frequency Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches