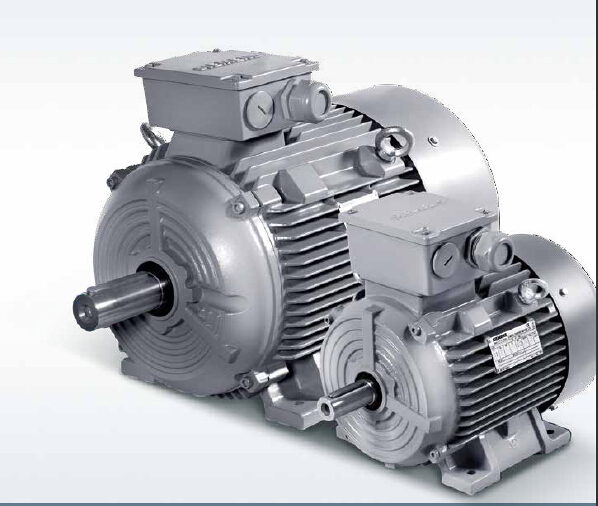

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Is the single-phase carbon brush motor a direct current motor or an AC motor?

- (1) motor is a DC motor with single-phase brushless motor or AC, there is also some DC motor AC and DC motor, such as most of the pistol electric drill AC and DC motor, AC and DC power can also be used to use.(2) the power supply of rectifier bridge is not from positive and negative pole, and the power supply of rectifier bridge must have positive and negative poles, otherwise it is not power supply of rectifier bridge.(3) bidirectional thyristor should be used in AC circuit. If your motor speed is bidirectional thyristor, it may be AC and DC motor.DC motor carbon brush and AC motor carbon brush is the same, so there are AC and DC dual series motor.

- Q: Is 3 phase AC induction motor specified in terms of Voltage, Current Power. I have heard that a motor can be operated over a range of volt, current power. then what do the rated values indicate. Also if a motor is specified as 48 V AC, 300A then can it be operated with a battery that could supply 48V DC... neglect all the losses the need for an alternator. Thanks in advance...

- The rated voltage is nominal voltage for which the motor is designed. The voltage can vary by plus or minus ten percent or so and the motor will still deliver the rated power without overheating so much that its useful life will be significantly shortened. The rated power is the power that the motor can deliver to the load 24 hours per day, seven days a week at rated voltage and rated ambient temperature for its expected lifetime. If the load is a little higher the motor's life will probably not be effected too much particularly if the temperature is not always at the maximum. If the load is less than the rated power, the motor will probably last longer than expected. The power delivered will be only what it takes to drive the load, so it can be much less than the rated power, but the motor will be less efficient if the load is a lot less than the rated power. The rated current is the current that the motor draws when it is operating at the rated voltage and delivering the rated power. If the voltage and/or load are above or below the rated values, the current will be above or below the rated value. Over a small range of voltage variation, the current changes in the opposite direction as the voltage change so that voltage multiplied by current will be about constant. Any battery of any voltage and sufficient power delivery capability could supply power provided that the DC power is converted to an AC voltage and frequency that are appropriate for the motor.

- Q: hw! Is it possible to run an AC motor mith a battery without using an inverter? How? plzz!?

- AC is entirely different current. Your car battery is DC (direct current). There is not likely enough voltage to run and AC device from a 12 volt car battery without an inverter.

- Q: If I wanted quot;run an AC motor backwardquot; ie to generate electricity (instead of electricity turning the axel). What do you need to do to get an AC motor to get it to generate electricity?

- Not okorder /

- Q: I let it rest for a while and it runs again for several min. but slowly grinds to a stop again. Sounds like bad motor. Capacitor is fairly new. I cleaned off the dust that was caked on and put the motor back in. It ran all night but did the same in the morning. What causes this you think? Also where do I buy a blower motor? And lastly, do I need to be licensed to buy AC parts?

- You could try oiling it. The HVAC industry uses Zoomspout oil for motors. Zoomspout oil is a high temp resistant non flamable oil that is specially formulated for sleeve bearing type motors. Buy it at any Ace hardware for $2. You can easily purchase a motor at any HVAC or appliance parts store. It is better to buy a motor based on amp draw than HP rating. Most parts stores will be glad to assist you in getting the rotation right, etc. The typical 1/3rd hp motor will run around $100 bucks. A good product to have is rust buster. A little on the screws will really help out.

- Q: Whether there is any change if we give ac supply to a dc motor?

- Nah, it'll be fine. Go for it.

- Q: I'm looking for a right angled dual shaft AC motor around 3hp, preferably geared. Any idea where I could find one?

- If you want the motor directly mounted to the gear box, you want a C flange style gearbox and a C flange style matching motor.

- Q: Why is DC motor speed regulating better than AC?

- The magnetic field of an AC motor is strongly coupled and time-varying, while the external conditions change and the speed changes as well, and it changes.

- Q: i have the following specifications for an ac motor with a built in constant torque drive.10:1 constant torque3600rpm250HPWhat Does the ratio mean?

- In specifications for a motor that is suitable for use with a variable frequency drive (VFD), 10:1 constant torque means that the motor can operate continuously at any speed between rated speed (3600 RPM) and one tenth of rated speed (360 RPM) without overheating while delivering rated torque at any speed. Rated torque is the torque required to produce rated horsepower at rated speed. Torque (lbs-ft) = Hp X 5252 / RPM. At 250 Hp, the VFD would be a separate control unit, not something built into the motor.

- Q: STC microcontroller through the relay control AC motor, in the motor start and stop the moment will be interrupted multiple times

- You've taken some of the usual anti jamming measures, but the key issues haven't been solved.1, the relay is isolated, without individual power supply, the photoelectric coupler input, if need to power (such as 6N137), must be separate power supply.Signal 2, optocoupler out, if it is low speed optocoupler, decreased along with gentle, easy to false triggering, you can add a Schmitt trigger in optocoupler after. It should solve your problem.3, SCM procedures can also do some anti disturbance processing, for example, some of the microcontroller's external interrupt, anti disturbance processing, you can open. If not, you can use the query operation, for example, each 10uS query IO once, 5 times continuously high, think that it is effective to obtain a high level, high level, set a mark, marked effective, inquiry into the 5 consecutive low level (if the middle high level again just count) is deemed effective falling edge.

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords