Waterproof Single Side Climbing Formwork For Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. CMAX Waterproof Single Side Climbing Formwork For Wall

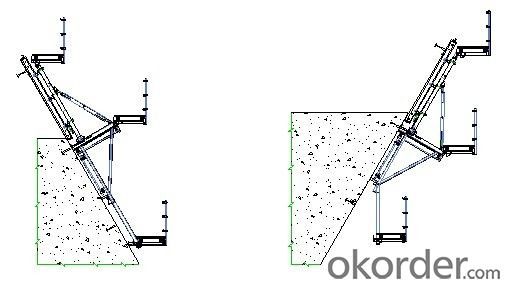

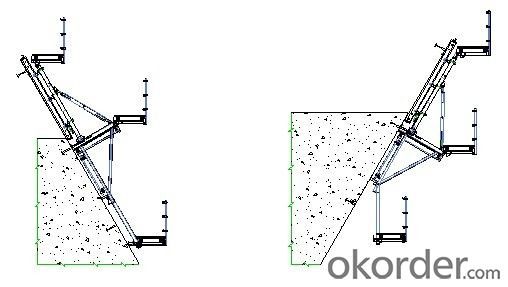

CMAX single side climbing formwork systems for the SCB 180 system are dams, locks, cooling towers, pier heads, tunnels, and bank vaults.

The formwork is simply tilted backwards when striking takes place. The 1.80 m wide bracket requires only a minimum of space.

2. Main Features of CMAX Waterproof Single Side Climbing Formwork

A) Economical and safe anchoring

The M30/D20 climbing cones designed especially for single-sided concreting using SCB180 in dam construction, and allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

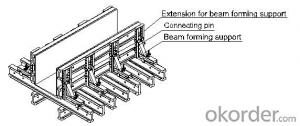

B) Stable and cost-effective for high loads.

Generous bracket spacing allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

C) Simple & flexible planning

With SCB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

D) Standard design, excellent applicability and interchangeable.

3. CMAX Waterproof Single Side Climbing Formwork Application

4. FAQ of CMAX Waterproof Single Side Climbing Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Waterproof Safe Single - Side Climbing Formwork For Wall, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of TWaterproof Safe Single - Side Climbing Formwork For Wall, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How is the hydraulic support moving

- Hydraulic support is a kind of hydraulic power unit which uses the liquid pressure to generate the support force and realize the automatic movement to carry out the roof support and management. It is an indispensable supporting equipment for comprehensive mechanized coal mining. Used to control the coal mining face pressure structure of the mine. The surface pressure is applied to the hydraulic support.

- Q: Climbing and floor scaffolding advantages and disadvantages

- Easy assembly and disassembly, erection flexible. As the length of the pipe is easy to adjust, fastener connection is simple, and thus can be adapted to a variety of flat, facade buildings and structures with scaffolding. More economical, simple processing, a low investment costs; if carefully designed scaffold geometry, pay attention to improve the use of steel pipe turnover, the amount of material can also achieve better economic results. Fastener steel pipe frame equivalent to about 15 kg per square meter of building steel.

- Q: What is a climbing frame?

- Climbing frame, also known as attached lift scaffolding, the equipment and equipment is the rapid development of the beginning of this century, a new scaffolding technology, construction technology in China has an important impact. It will be high operations into a low operation, the floating operations into the frame internal operations, with significant low-carbon, high-tech content and more economical, more secure, more convenient and so on.

- Q: Is the scaffolding scaffolding?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q: The difference between climbing and sliding mode

- Sliding mold is pouring process, the concrete has not yet solidified, it will continue to lift or move the template, so that the formation of the template and pouring concrete between the relative sliding climbing mold is pouring a template, to enhance the climbing frame, and then install A template

Send your message to us

Waterproof Single Side Climbing Formwork For Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords