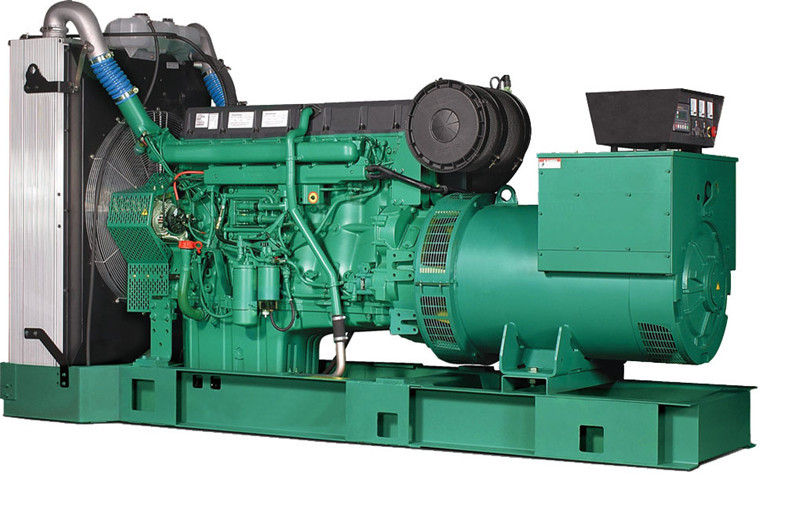

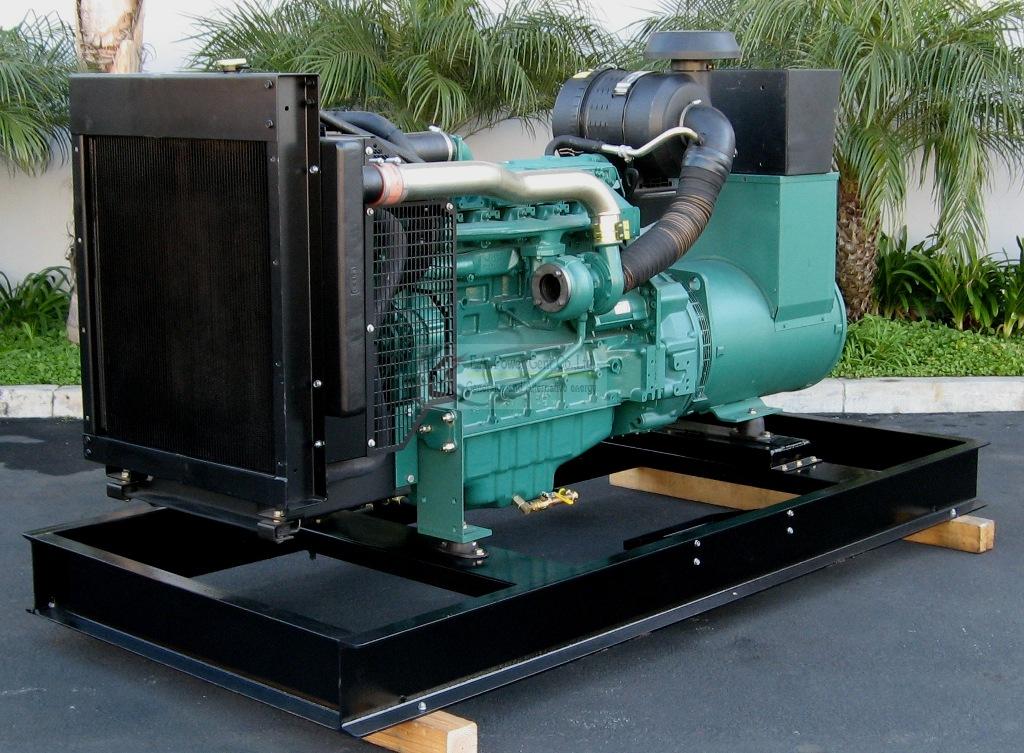

Volvo Genset Diesel Generator For Home Use 85kva - 625kva

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Volvo Genset Diesel Generator For Home Use 85kva - 625kva

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNRV95 | 68 | 85 | 76 | 95 | TD520GE | ≤213 | 4 | 4.67 | 108*130 |

GNRV110 | 80 | 100 | 88 | 110 | TAD531GE | ≤211 | 4 | 4.67 | 108*130 |

GNRV137 | 100 | 125 | 110 | 137 | TAD532GE | ≤204 | 4 | 4.67 | 108*130 |

GNRV165 | 120 | 150 | 132 | 165 | TAD731GE | ≤204 | 6 | 6.51 | 108*130 |

GNRV200 | 144 | 180 | 160 | 200 | TAD732GE | ≤204 | 6 | 6.73 | 108*130 |

GNRV225 | 160 | 200 | 180 | 225 | TAD733GE | ≤204 | 6 | 7.28 | 108*130 |

GNRV275 | 200 | 250 | 220 | 275 | TAD734GE | ≤200 | 6 | 7.28 | 108*135 |

GNRV350 | 250 | 312 | 280 | 350 | TAD941GE | ≤198 | 6 | 9.36 | 131*150 |

GNRV413 | 300 | 375 | 330 | 413 | TAD1241GE | ≤198 | 6 | 12.3 | 131*150 |

GNRV450 | 320 | 400 | 360 | 450 | TAD1242GE | ≤198 | 6 | 12.3 | 131*150 |

GNRV500 | 360 | 450 | 400 | 500 | TAD1640GE | ≤198 | 6 | 16.12 | 144*165 |

GNRV560 | 400 | 500 | 450 | 560 | TAD1641GE | ≤198 | 6 | 16.12 | 144*165 |

GNRV625 | 450 | 563 | 500 | 625 | TAD1642GE | ≤198 | 6 | 16.12 | 144*165 |

GNRV688 | 500 | 625 | 550 | 688 | TAD1643GE | ≤198 | 6 | 16.12 | 144*165 |

The specification of engine:

1) Genuine Sweden volvo industrial diesel engine

2) Multi-cylinder in-line or veer engine, 4-stroke, direct injection

3)Naturally aspirated, turbocharged, water cooled or turbocharged with air intercooler

4)Machinery or electronic governing

5) Fuel injection pump

6) Electric motor starting system

7) Forged steel crankshaft, cast iron cylinder and replaceable wet type cylinder line

8)Low discharge, and low fuel consumption

9) Installed conveniently and maintain easily

The specification of alternator:

1)alternator model: stamford, Leroy, Marathon.Engga

2)regulator: AVR automatic voltage regulating

3)insulation degree: H degree

4)power factor:3 phase 4 wire

5)Motor: bronze brushless

6) IP21-23 enclosure

Control system:

1) Automatic alarm system: the unit hasunit has the acousto-optics alarm system and arreand arrestor for anr for any situation as the start defeat, the water is over tempeer temperature, the oil pulls down, over speed, over load and over current

2) Operation display:

i) Unit voltage, tri-phase load current and frequency display

ii) Water temperature, oil pressure display

iii) Fuel level, fuel temperature display

iv) Audible Audible and visual alarm lamps and buzzers

Accessories:

1) Standard accessories: Standard 40 radiator mounted on skid, Common steel frame, circuit breaker, damper, exhaust silencer, flexible pipe, battery and connecting wires, Standard tools kit, operation manual and document.

2) Optional accessories: Engine coolant and oil heater, alternator space heater, cooling for heat exchanger, communication interface, battery charger by main supply, daily fuel tank, ATS and paralleling system, soundproof canopy and moving trailer.

Warranty policy

Guarantee for one year or 1000 hours whichever reach first from ex-factory date. During the guarantee period, Genor will provide the free easy-damageable spare parts of diesel engine caused by our quality of production or raw material. After expiration, Genor provides cost spare parts maintenance of gensets.

- Q: Can ordinary motors be matched with inverters?

- Can, but not the long run under low frequency, which can't run for a long time in 30 hz, because: 1. The inverter output is not a standard sine wave, the large amount of harmonic, harmonic exacerbate motor hair machine; The cooling fan of the normal motor and the motor coaxial, the cooling fan speed decreases and the cooling effect is decreased when the motor is running at low speed.

- Q: What is the difference between a general motor and a converter machine?

- Variable frequency motor is of stator and rotor slot number and the trough, winding form, distribution and structure of coil has carried on the special design, with appropriate inductance restrain harmful system harmonic, the motor can have enough torque under high speed and overload capacity, and at low speeds can start properly, make the motor has enough torque and stable running performance; There are also differences in the external and heat modes of the converter motor. In case of low demand, ordinary motors can replace the frequency conversion machine.

- Q: How does servo motor understand? What is a servo motor? What about motors? What's different about servo motors and other motors?

- Servo motor (servo motor) is the engine that controls the operation of mechanical components in servo systems. The servo motor can control the speed, the position precision is very accurate, can convert voltage signal to torque and speed to drive the control object. Servo motor rotor speed controlled by the input signal, and can be rapid response, in the automatic control system, is used as actuators, and has a small electromechanical time constant, high linearity, initiating character such as voltage, can convert the received electrical signal to the motor shaft angular displacement or angular velocity on output. Divided into two major categories of dc and ac servo motor, its main characteristic is, when the signal voltage is zero no rotation, speed decreases with the increase of torque and uniform.

- Q: How does the motor stop

- Install a red emergency stop button (commonly known as a large cap) in the control circuit and place it in handy. You need to stop, just click.

- Q: What's the difference between a TEFC motor and a regular motor

- The TEFC motor is cooled by the air of the motor casing, and the air is provided by the fan mounted on the motor shaft. The common motor USES the fan ventilation cooling on the shaft of the machine, forcing the air to flow through the open end of the motor, from both sides.

- Q: How do you think a motor is an ordinary motor or a servo

- There is another communication cable interface. General servo motor will be in the position sensor, such as possibly braking device, the device control and information feedback is generally via a special communication cable. But not get communication cable is servo motor, some contain many large motor temperature sensor (bearing, winding), such as also need special communication cable, but it is not servo motor. In addition, many servo motor enclosures are square, and ordinary motors are round.

- Q: Can variable frequency control motor be used as a general motor?

- It depends on what kind of structure it is! If it's a three-phase asynchronous motor, you can

- Q: Does the frequency conversion machine speak louder than the ordinary motor?

- No, only when the frequency is low. It's basically the same as a normal machine in 10HZ.I hope my answer will help you

- Q: What is a permanent magnet motor? Is there a difference between a regular motor

- The difference between a permanent magnet and a conventional motor is: Magnetic field properties. Permanent magnet motors are made without the external energy to maintain their magnetic field; Ordinary motors require electricity to flow in to have a magnetic field. Rotor structure. The permanent magnet motor rotor is fitted with a permanent magnet. Excitation coil is installed on ordinary motor rotor. Applicable occasions. Permanent magnet motors are used for small power occasions; General motors, especially exciter motors, are often used in high-power situations. Electric machinery, electric machinery, is an electromagnetic device that realizes electrical energy conversion or transmission according to electromagnetic induction law. In the circuit, the letter M indicates that its main function is to generate drive torque as the power source of electrical or mechanical power.

- Q: What is the meaning of the motor from cold and cold?

- Motor self-cooling refers to the wind blade of the rotor, which starts cooling during the operation of the motor. The motor is cooled by an electric motor plus cooling fan. Normal three-phase ac asynchronous motors are used for cold, and it is very cold when it is unable to heat the electric motors and heat the heat. Such as frequency conversion motor, dc motor, etc., normally use force cooling.

Send your message to us

Volvo Genset Diesel Generator For Home Use 85kva - 625kva

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches