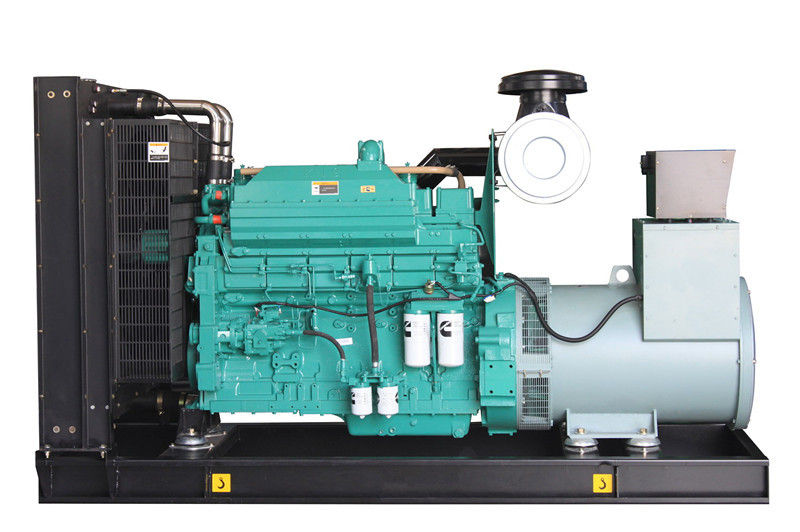

Soundproof Cummins Genset Diesel Generator / Auto Start Generator Control Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soundproof Cummins Genset Diesel Generator / Auto Start Generator Control Panel

Quick details

Bore X Stroke:102*120mm

Type:4-stroke

Engine:4B3.9-G

Certificate: CE, ISO9001

Specifications:

1. Genuine Commins industrial diesel engine water cooling

2.Stamford Brushless Alternator

3. 24V DC start motor and storage battery

4. Multi-cylinder in-line or veer engine, 4-stroke, direct injection

5.Deepsea, Smartgen Digital auto-start panel

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNRC30 | 20 | 25 | 24 | 30 | 4B3.9-G | ≤229 | 4 | 3.9 | 102*120 |

GNRC35 | 24 | 30 | 28 | 35 | 4BT3.9-G | ≤214 | 4 | 3.9 | 102*120 |

GNRC56 | 40 | 50 | 45 | 56 | 4BTA3.9-G | ≤215 | 4 | 3.92 | 102*120 |

GNRC63 | 45 | 56 | 50 | 63 | 4BTA3.9-G | ≤215 | 4 | 3.92 | 102*120 |

GNRC70 | 50 | 63 | 56 | 70 | 6BT5.9G1 | ≤215 | 6 | 5.88 | 102*120 |

GNRC106 | 78 | 98 | 85 | 106 | 6BT5.9G | ≤215 | 6 | 5.88 | 102*120 |

GNRC125 | 90 | 113 | 100 | 125 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC150 | 104 | 130 | 120 | 150 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC165 | 120 | 150 | 132 | 165 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC200 | 140 | 175 | 160 | 200 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC225 | 160 | 200 | 180 | 225 | 6CTAA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC275 | 200 | 250 | 220 | 275 | 6LTAA8.9-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC313 | 220 | 275 | 250 | 313 | NTA855-G1A | ≤206 | 6 | 14 | 140*152 |

GNRC350 | 250 | 313 | 275 | 350 | NTA855-G2 | ≤207 | 6 | 14 | 140*152 |

GNRC400 | 280 | 350 | 310 | 400 | NTA855-G4 | ≤208 | 6 | 14 | 140*152 |

GNRC413 | 300 | 375 | 330 | 413 | NTAA855-G7 | ≤206 | 6 | 14 | 140*152 |

GNRC450 | 320 | 400 | 360 | 450 | NTAA855-G7A | ≤206 | 6 | 14 | 140*152 |

GNRC500 | 360 | 450 | 400 | 500 | KTA19-G3 | ≤203 | 6 | 18.9 | 159*159 |

GNRC550 | 400 | 500 | 440 | 550 | KTA19-G4 | ≤203 | 6 | 18.9 | 159*159 |

GNRC605 | 440 | 550 | 484 | 605 | KTAA19-G6 | ≤204 | 6 | 18.9 | 159*159 |

GNRC625 | 450 | 563 | 500 | 625 | KTAA19-G7 | ≤204 | 6 | 18.9 | 159*159 |

GNRC700 | 500 | 625 | 560 | 700 | KTA38-G | ≤206 | 12 | 37.8 | 159*159 |

GNRC712 | 520 | 650 | 570 | 712 | QSK19-G3 | ≤206 | 6 | 19 | 159*159 |

GNRC800 | 580 | 720 | 640 | 800 | KTA38-GA | ≤209 | 12 | 37.8 | 159*159 |

GNRC825 | 600 | 750 | 660 | 825 | KTA38-G2 | ≤210 | 12 | 37.8 | 159*159 |

GNRC888 | 640 | 800 | 710 | 888 | KTA38-G2B | ≤210 | 12 | 37.8 | 159*159 |

GNRC975 | 720 | 900 | 780 | 975 | KTA38-G2A | ≤210 | 12 | 37.8 | 159*159 |

GNRC1075 | 800 | 1000 | 860 | 1075 | KTA38-G5 | ≤202 | 12 | 37.8 | 159*159 |

GNRC1375 | 1000 | 1250 | 1100 | 1375 | KTA50-G3 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1375 | 1100 | 1375 | 1310 | 1650 | KTA50-G8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1650 | 1200 | 1500 | 1340 | 1675 | KTA50-GS8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1675 | 1350 | 1688 | 1500 | 1875 | QSK60-G3 | ≤215 | 16 | 60 | 159*159 |

GNRC1875 | 1500 | 1875 | 1650 | 2063 | QSK60-G3 | ≤215 | 16 | 60 | 159*190 |

GNRC2063 | 1600 | 2000 | 1800 | 2250 | QSK60-G4 | ≤215 | 16 | 60 | 159*190 |

Genset Features:

1. Genuine Commins industrial diesel engine

2. Radiator 40°C max, fans are driven by belt, with safety guard

3. Genuine stamford. Leroy somer, marathonm, engga alternator

4. Choice of manual/auto and AMF control panels and protection systems

5. Digital auto-start panel

6. Anti Vibration Suspension Absorber

7. Dry type air filter, fuel filter, oil filter

8. 10-hour operation base tank

9.Mould case circuit breaker

10. 24V DC start motor and storage battery

11. 24V charge alternator

12. 24V batteries, rack and cable

13. Rippl;e flex echaust pipe, exhaust siphon, flange, and muffler

14. Comply with ISO and CE standards

15. All generator sets are gone through rigorous testing before beging released to the market place, including 50% load, 75% load, 100% load and all protection function(over speed stop, high water temperature, low oil pressure, battery charging fail, emergency stop)

Engine Features:

1. Genuine Cummins industrial diesel engine

2. Multi-cylinder in-line or veer engine, 4-stroke, direct injection

3. Naturally aspirated, turbocharged, water cooled or turbocharged with air intercooler

4. Machinery or electronic governing

5. Fuel injection pump

6. Electric motor starting system

7. Forged steel crankshaft, cast iron cylinder and replaceable wet type cylinder liner

8. Low discharge, and low fuel consumption

9. Installed conveniently and maintain easily

Alternator Features:

1. World famous brand AC alternator: Leroy Somer, Stamford, Marathon, ENGGA

2. Brushless, 4 poles, rotation magnet

3. IP21-23(NEMA1) enclose is standard for all industrial alternators

4. H class insulation system

5. AVR self-regulated, voltage regulation rate: ≤±1%

6. Simple installation and maintenance with easy access to terminals, rotating diodes and coupling bolts

7. Wide range of flange adaptors and single bearing disc coupling

8. Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

9. Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Digital Control panel

Controller Brand: Smartgen, Deepsea,ComAp

Control Panel: English interface,LED screen and touch buttons.

Main Functions:

1- Display loading power, voltage, currenct, frequency, speed, temperature, oil pressure, running time etc.

2- Warning when low or high voltage, low or high frequency, over current, over or low speed, low or over battery voltage etc.

3- Over load protection, over/under frequency protection, over/under/imbalance voltage protection, and low oil shutdown

Super Soundproof/Silent Box:

1. Excellent ventilation

2. Oil tank mounted on base frame for 12 Hours working

3. Highly Corrosion Resistant construction

4. Excellent Access for Maintenance

5. Security and Safety

6. 1m<80DBA / 7m<70DBA

- Q: Does the motor have a good brush or no brush?

- The carbon brush looks a bit like a pencil eraser, with a wire on top. There is a lot of small size. As a sliding contact, carbon brushes are widely used in many electrical devices. The products are made of graphite, lipographene, metal (copper, silver) graphite.

- Q: If the value of the capacitor on a motor is smaller, it can also be installed in other motors

- Don't keep using it. The capacity will continue to decrease until it is completely invalidated and has no value.

- Q: The governor has changed a new one, with the governor to zero, but the motor is still turning! The motor has a different sound, such as the sound of iron and iron friction!

- This is basic rule out the problem of speed governor, the problem may be broken in speed resistance speed governor is set to zero, the resistance should be in maximum, or feedback signal input connection circuit, it is suggested that can be replaced. Speed machine: governor (called) is a kind of automatic adjustment device, according to the change of the diesel engine load, it automatically increase or decrease in fuel injection pump oil, the diesel engine to run at a steady speed. Governor has been in the industry dc motor speed regulation, conveyor belt speed, lamplight illume mediation, computer power supply cooling, dc fan, etc., used widely. Governor according to its working principle is different, can be divided into mechanical, pneumatic, hydraulic, mechanical pneumatic compound, complex mechanical hydraulic and electronic, and other forms.

- Q: What is a hydraulic motor

- The high speed motor gear motor has the advantages of small size, light weight, simple structure, good technology, not sensitive to the pollution of the oil, the shock resistance and small inertia. The disadvantages include higher torque ripple, low efficiency, low starting torque (60% to rated torque) and low speed stability.

- Q: Can variable frequency control motor be used as a general motor?

- It should be possible because the converter also needs to be running at 50HZ The question becomes the answer The BM type is the rated frequency 50HZ frequency conversion asynchronous motor

- Q: Are motors and motors a concept?

- Motor is a general designation, because there are generators, motors, and dc motor, dc generator, etc., so the motor is a general designation, and the motor is not a concept.

- Q: The motor does not turn except sound

- The motor shaft and shaft sleeve clearance is too large, or motor rotor momentum is too big, a magnetic field when electric motor internal rotor and the stator attraction bruised (commonly known as "chamber"), unable to turn. At this point the electric current will soar, if not handled in time, the machine will burn down.

- Q: Does the frequency conversion machine speak louder than the ordinary motor?

- And add in waveform on the ordinary motor through a special filter commonly, passes through the filter, plus waveforms on the motor for the standard sine wave, harmonic inside is very good, basically is the fundamental wave, so no noise. It looks something like this.

- Q: What is the difference between the riot motor and the ordinary motor? How does it work differently from ordinary motors? Is it possible to be overloaded with ordinary motors? Please help me, thank you.

- Structure: The motor and generator are basically the same in the overall structure, both of which have reversibility. Motor: the coil is turned on by an ampere force in the magnetic field and is used to drive other object movements during the movement. Dynamo: the magnetic force of the coil, which is driven by a physical force, is used to cut the magnetic force and generate the current.

- Q: Why does the direct start-up of high power motors affect the voltage of the grid

- Because of the asynchronous motor starting, the rotor has not turned up, the stator rotating magnetic field cutting speed relative to the rotor conductors, in rotor induction electric potential is very big, so the current is very big, if starting directly from grid, starting current can reach 4 to 7 times the rated current, and is the most current inductive current, this would have had a big impact on the grid: 1) the large starting current will be produced on the transmission line, the larger voltage drop; 2) because so much of the starting current, most of it is a perceptual current, will cause a demagnetization effect on the grid, and will also cause the grid voltage to fluctuate.

Send your message to us

Soundproof Cummins Genset Diesel Generator / Auto Start Generator Control Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords