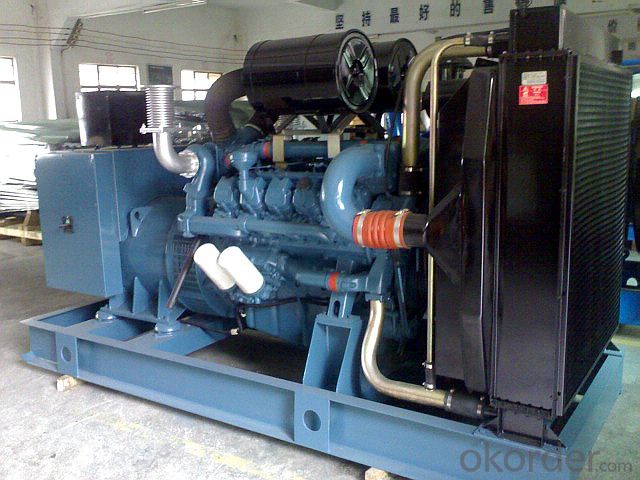

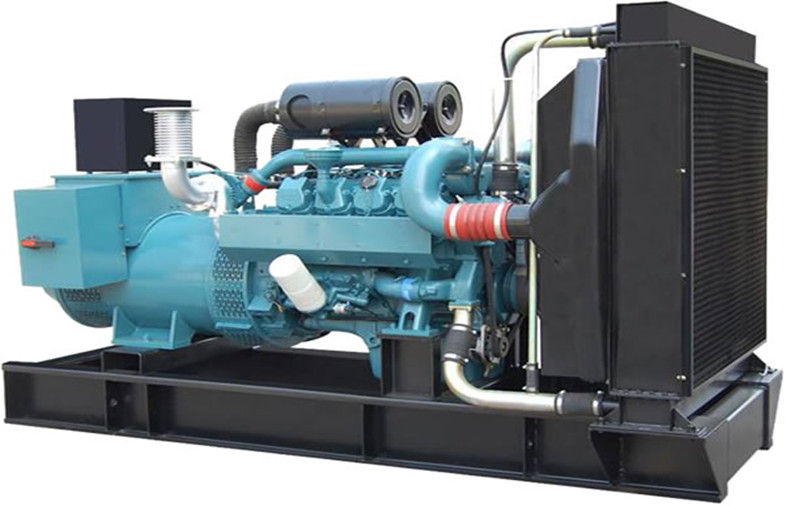

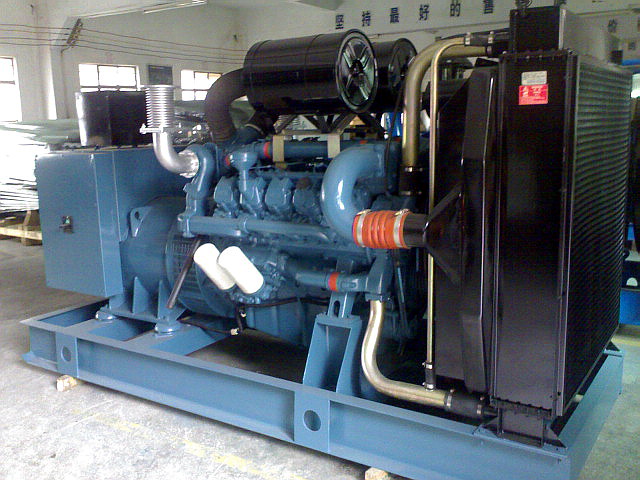

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80kva to 625kva Standby Power Generator

1.Doosan Engine With Stamford Alternator

2.High Efficiency , Low Fuel Consumption

3.12 Months Warranty ,CE Approved

80kva - 600kva Doosan Power Genset Diesel Generator Standby

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNR70DS | 50 | 62.5 | 55 | 70 | DB58 | ≤216 | 6 | 8 | 102*118 |

GNR94DS | 72 | 90 | 80 | 94 | D1146 | ≤216 | 6 | 8 | 111*139 |

GNR138DS | 100 | 125 | 110 | 138 | D1146T | ≤216 | 6 | 8 | 111*139 |

GNR200DS | 140 | 175 | 160 | 200 | D086TI-1 | ≤216 | 6 | 8 | 111*139 |

GNR225DS | 160 | 200 | 180 | 225 | P086TI | ≤216 | 6 | 8 | 111*139 |

GNR275DS | 200 | 250 | 220 | 275 | P126T1 | ≤216 | 8 | 8 | 123*155 |

GNR310DS | 220 | 275 | 250 | 310 | P126TI | ≤216 | 6 | 11 | 123*155 |

GNR350DS | 250 | 310 | 280 | 350 | P126T11 | ≤215 | 6L | 11 | 128*142 |

GNR413DS | 300 | 375 | 330 | 413 | P158LE-1 | ≤213 | V8 | 14.6 | 128*142 |

GNR450DS | 320 | 410 | 360 | 450 | P158LE | ≤212 | V8 | 14.6 | 128*142 |

GNR500DS | 360 | 450 | 400 | 500 | P158LE | ≤212 | V10 | 18.3 | 128*142 |

GNR550DS | 400 | 500 | 440 | 550 | P180LE | ≤212 | V10 | 18.3 | 128*142 |

GNR625DS | 450 | 560 | 500 | 625 | P222LE-I | ≤211 | V12 | 21.9 | 128*142 |

GNR700DS | 500 | 625 | 560 | 700 | P222LE-S | ≤211 | V12 | 21.9 | 128*142 |

Diesel engine:doosan engine

a) Multi-cylinder in-line or veer engine.4-stroke,direct injection

b) Governer Method:electrical or mechanical governor

c) Water cooling

d) Intake method:Natural apirated or turbocharged

e) Electric motor starting system

Alternator: Stamford,LeroySomer, Marathon,Engga

a) Brushless, 4 poles, rotation magnet

b) IP21-23(NEMA1) enclose is standard for all industrial alternators

c) H class insulation system

d) AVR self-regulated, voltage regulation rate: ≤±1%

e) Wide range of flange adaptors and single bearing disc coupling

f) Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

g) Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Control plane :

a)Automatic alarm system: the unit has the acoustic-optics alarm system and arrestor for any situation as the start defeat, the water is over temperature the oil pulls down, over speed, over load and over current

b) Operation display:

i)Unit voltage, tri-phase load current and frequency display

ii)Water temperature, oil pressure display

iii)Fuel level, fuel temperature dieplay

iv)Audible and visual alarm lamps and buzzers

c)Emergency stop button

d)Three protection

Accessories

a) Standard accessories: Standard 40 radiator mounted on skid, Common steel frame, circuit breaker, damper, exhaust silencer, flexible pipe, battery and connecting wires, Standard tools kit, operation manual and document.

b) Optional accessories: Engine coolant and oil heater, alternator space heater, cooling for heat exchanger, communication interface, battery charger by main supply, daily fuel tank, ATS and paralleling system, soundproof canopy and moving trailer.

Warranty policy

Guarantee for one year or 1000 hours whichever reach first from ex-factory date. During the guarantee period, Genor will provide the free easy-damageable spare parts of diesel engine caused by our quality of production or raw material. After expiration, Genor provides cost spare parts maintenance of gensets.

- Q: What is the structural difference between a two-speed motor and a regular motor

- There are two sets of coils in the two-speed motor slot, and the ordinary motor has a set of coils through the special switch control speed. This is the main difference.

- Q: If the value of the capacitor on a motor is smaller, it can also be installed in other motors

- The capacitance of this capacitor is so unstable that it can't be used!I hope my answer will help you.

- Q: What is the difference between a step motor and an ordinary motor

- A dc motor usually requires only two lines, and the step motor requires 4-5 jumper lines The speed of dc motor is higher, and the speed of stepping motor is slower The Angle of rotation of the dc motor is difficult to calculate accu

- Q: What is a hydraulic motor

- Hydraulic motor is hydraulic motor, hydraulic motor is also known as the oil motor, mainly used in injection molding machinery, ships, Yang machine, engineering machinery, construction machinery, coal machinery, mining machinery, metallurgical machinery, ship machinery, petrochemical industry, port machinery, etc.

- Q: Precautions for water cooled motor

- (1) water-cooled air-cooled motor during normal operation of temperature should not exceed the permitted limits. When running, the personnel on duty should always pay attention to monitor the temperature of each part. (2) monitoring water-cooled air-cooled motor load current. Water-cooled air-cooled motor overload or failure occurs, can cause the stator current surge, water-cooled air-cooled motor overheating. Electrical equipment should have current meter monitor water-cooled air-cooled motor load current, the normal operation of water-cooled air-cooled motor load current shall not exceed the rated current value stipulated in the nameplate. (3) to monitor the change of supply voltage, frequency and voltage unbalance degree. The power supply voltage and frequency is too high or too low, three-phase voltage imbalance will cause current unbalance, can cause water-cooled air-cooled motor overheating or other abnormal phenomena. Current unbalance degree should not exceed 10%.

- Q: The difference between the frequency converter and the ordinary motor

- Variable frequency motor is more than ordinary motor, and the specific advantages of frequency conversion motor are: 1, have the start function The resistance of stator and rotor is reduced by electromagnetic design Adjust to the constant speed change under different working conditions 4, to some extent energy saving

- Q: A 2.2 KW motor will require a lot of electricity a day

- It is not accurate to calculate simply because you are not considering the load rate of the motor, and the load rate of the pump is less than 75%. The most accurate method is to install the meter.

- Q: The difference between PWM and general motors

- PWM motor is frequency conversion motor, that is, the inverter output waveform is not filtering after PWM wave, ordinary motor generally as a standard, usually sinusoidal waveform, if use frequency converter drive, also need to add after the inverter output filter circuit, or general motors can not stand, fever is serious, but also is frequency conversion motor PWM motor is ok.

- Q: What is the difference between servo motor and general motors?

- Thus, ac synchronous motor belongs to precision adjustment, the encoder is not easy to hit, dust, vibration, in use process, if maintain undeserved can cause all kinds of fault, not general motor maintenance personnel can deal with it.

- Q: What is the electric motor in the car seat?

- The two lines are the wires of the motor rotor, and the three lines are the line of the motor controller (the seat control switch is connected to the controller of the seat motor to be controlled before and after the motor is controlled).

Send your message to us

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords