different kinds of plastic formworks used in construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

More and more people in the world would like to importPlasticformwork from China since recentyears. Plastic formwork is a new type construction material in the construction industry andpeople could buy good quality at a very good price from Chinese market. In this way, the distributors make more profit and the end users could save more cost. Before you decide to purchase this kind of plastic formwork, you need to know how plastic formwork sprung up and grasped the market.

2. The Advantages of Plastic Formwork:

1:easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2:modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

3:strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

4:enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

5:consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

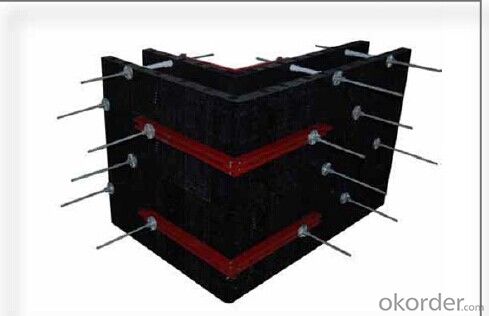

3. Images for Plastic Formwork:

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: What types of concrete structures can be formed using steel frame formwork?

- Steel frame formwork is a versatile construction technique that can be utilized to construct various types of concrete structures. Some of the common uses of steel frame formwork include: 1. Tall buildings: Steel frame formwork is an ideal option for erecting high-rise buildings due to its exceptional strength and stability. It provides the necessary support to pour concrete at significant heights, ensuring the structural integrity of the building. 2. Bridges and flyovers: Steel frame formwork is extensively used in the construction of bridges and flyovers. It offers a robust framework that can withstand heavy loads and allows for the creation of complex shapes and curves required in these structures. 3. Industrial structures: Steel frame formwork is commonly employed in the construction of industrial buildings such as factories, warehouses, and manufacturing plants. Its durability and flexibility make it suitable for accommodating large open spaces and heavy machinery. 4. Retaining walls: Steel frame formwork is an excellent choice for building retaining walls. It provides a strong and rigid structure capable of withstanding the pressure exerted by the retained soil, ensuring the stability of the wall. 5. Water tanks and reservoirs: Steel frame formwork is frequently used in the construction of water tanks and reservoirs. Its ability to create watertight structures makes it suitable for storing water, ensuring there are no leaks or seepages. 6. Tunnels and underground structures: Steel frame formwork is utilized in the construction of tunnels and underground structures due to its capacity to withstand high pressure and provide a secure framework for pouring concrete. 7. Infrastructure projects: Steel frame formwork is widely employed in infrastructure projects such as highways, railways, and airports. It enables the construction of sturdy and durable structures capable of withstanding heavy traffic and adverse weather conditions. To sum up, steel frame formwork is a versatile technique for creating a wide range of concrete structures, including high-rise buildings, bridges, industrial buildings, retaining walls, water tanks, tunnels, and infrastructure projects. Its strength, stability, and flexibility make it a preferred choice for numerous construction applications.

- Q: How does steel frame formwork affect construction timelines?

- Construction timelines can be significantly impacted by the use of steel frame formwork. One primary advantage of steel frame formwork is its durability and strength, which enables quicker and more efficient construction processes. Steel frames provide a stable and rigid structure, reducing the need for additional support and reinforcement, thus expediting construction. Moreover, steel frame formwork is reusable, meaning it can be utilized multiple times for different projects. This cuts down on the time required for formwork assembly and disassembly, as well as the expenses and efforts involved in sourcing and purchasing new formwork materials for each project. Additionally, steel frame formwork remains resistant to warping, shrinking, and expanding, ensuring that it retains its original shape and size during construction. Consequently, adjustments or rework are unnecessary, saving both time and effort. The versatility of steel frame formwork additionally contributes to accelerated construction timelines. It can be easily customized and adapted to various shapes and sizes, making it effortless to construct complex structures. This flexibility shortens the time needed for formwork design and preparation, further hastening the construction process. In summary, the use of steel frame formwork in construction projects leads to substantial time savings. Its strength, durability, reusability, resistance to deformation, and adaptability all contribute to faster construction timelines, enabling earlier project completion and reduced costs.

- Q: How does steel frame formwork accommodate for changes in concrete temperature?

- Steel frame formwork accommodates for changes in concrete temperature through its flexibility and thermal conductivity properties. Firstly, the steel frame formwork system is designed to be flexible and adjustable. This allows it to adapt to changes in the dimensions of the concrete elements caused by temperature variations. As concrete expands or contracts due to temperature changes, the steel formwork can be easily adjusted to accommodate these alterations. This flexibility ensures that the formwork remains in its proper position, preventing any distortion or cracking of the concrete structure. Secondly, steel has a high thermal conductivity, which means it can effectively transfer heat. This property allows the steel frame formwork to quickly absorb and dissipate the heat generated by the setting and curing of concrete. As the concrete temperature rises, the steel formwork helps in dissipating the excess heat, preventing any potential damage to the concrete due to excessive temperature rise. Similarly, during cold weather conditions, the steel frame formwork helps in conducting heat and preventing the concrete from freezing, which can lead to cracking and reduced strength. Overall, the flexibility and thermal conductivity properties of steel frame formwork ensure that it can effectively accommodate for changes in concrete temperature. This helps in maintaining the structural integrity of the concrete elements and ensuring a durable and long-lasting construction.

- Q: How does steel frame formwork ensure a smooth concrete finish?

- Steel frame formwork ensures a smooth concrete finish through its rigidity and stability. The steel frames are designed to be strong and sturdy, providing a solid structure that supports the weight and pressure of the concrete. This prevents any deformation or movement of the formwork during the pouring and curing process. Additionally, the steel frames are built with precision and accuracy, allowing for the creation of straight and level surfaces. This ensures that the concrete is poured evenly and uniformly, resulting in a smooth finish without any irregularities or imperfections. Furthermore, steel frame formwork allows for the easy installation and removal of formwork panels. This enables contractors to quickly and efficiently assemble and disassemble the formwork, reducing the chances of any damage or disturbance to the concrete surface. The smooth removal of the formwork panels also eliminates the risk of leaving behind any marks or blemishes on the concrete. Overall, the use of steel frame formwork provides a reliable and effective solution for achieving a smooth concrete finish. Its strength, stability, precision, and ease of use contribute to the creation of a high-quality surface that meets the desired aesthetic and functional requirements.

- Q: Are there any limitations to the number of reuses for steel frame formwork panels?

- Yes, there are limitations to the number of reuses for steel frame formwork panels. While steel is a durable and strong material, it is not invincible and can deteriorate over time with repeated use. Some of the limitations include: 1. Fatigue: With each use, the steel frame formwork panels are subjected to various loads and stresses. Over time, this can lead to fatigue, causing the steel to weaken and eventually fail. 2. Corrosion: Steel is susceptible to corrosion when exposed to moisture, chemicals, or environmental conditions. Corrosion can weaken the structural integrity of the panels, making them less suitable for reuse. 3. Wear and tear: The repeated assembly, disassembly, and transportation of steel formwork panels can cause wear and tear. This can lead to deformation, cracks, or other damage, making the panels less effective and safe for reuse. 4. Surface imperfections: During the concrete pouring process, the formwork panels can experience surface imperfections such as scratches, dents, or concrete residue buildup. These imperfections can affect the quality of subsequent concrete pours and may require repair or replacement of the panels. 5. Changes in construction requirements: Over time, there may be changes in construction methods, designs, or building codes that render older steel formwork panels obsolete. This can limit their reuse as they may not meet the updated requirements. To ensure the safe and effective reuse of steel frame formwork panels, regular inspections, maintenance, and repairs are necessary. It is also important to follow manufacturer guidelines and industry best practices to determine the suitable number of reuses for each panel, taking into account its condition, history of use, and the specific construction project requirements.

- Q: Can steel frame formwork be used for both precast and cast-in-place concrete walls?

- Yes, steel frame formwork can be used for both precast and cast-in-place concrete walls. The versatility of steel frame formwork allows for its application in various construction methods, making it suitable for both precast concrete walls, which are manufactured off-site, and cast-in-place concrete walls, which are poured on-site.

- Q: How does steel frame formwork affect the overall insulation of a structure?

- Steel frame formwork does not directly affect the overall insulation of a structure as it is primarily used as a temporary support system during construction. Insulation is typically added separately to the walls, roof, and floors of a structure to provide thermal resistance and maintain desired temperature levels.

- Q: Can steel frame formwork be used for historical and heritage restoration projects?

- Indeed, historical and heritage restoration projects can utilize steel frame formwork. By offering a robust and long-lasting framework for concrete pouring, steel frame formwork permits the precise execution of intricate designs and details. This quality renders it suitable for restoration endeavors that demand accurate reconstruction or repair of historical edifices while preserving their original appearance and structural soundness. Moreover, steel frame formwork can be tailored to meet specific project requirements, ensuring its compatibility with the unique challenges associated with the restoration of historical and heritage buildings. Its adaptability and strength establish it as a practical choice for such projects, empowering craftsmen to meticulously restore and safeguard the architectural heritage of yesteryears.

- Q: Problems and solutions of bamboo plywood formwork

- The main problems and reasons of bamboo plywood formwork(1) the thickness tolerance problem is not only used as the panel of the steel frame bamboo plywood, but also used as the veneer plywood.

- Q: Are there any limitations to the size or shape of concrete structures that can be formed using steel frame formwork?

- Steel frame formwork has certain limitations regarding the size and shape of concrete structures that can be constructed. One constraint is the maximum achievable height of the structure. Due to the stability and strength of the steel frames, there are height restrictions for steel frame formwork systems. If the structure surpasses the height limit, additional support systems like scaffolding or shoring might be necessary to maintain the formwork's stability. Another limitation concerns the complexity of the shape that can be achieved. Steel frame formwork is primarily designed for creating straight, rectangular, or square structures. Although some curved or irregular shapes can be achieved, it may require modifications or customizations to the formwork system, leading to increased complexity and construction costs. Moreover, the size and weight of the formwork panels can also impose limitations. Steel frame formwork panels are typically heavy, and handling them becomes more challenging as their size increases. This can make it difficult to maneuver and assemble the formwork panels for larger and more intricate structures. Additionally, the availability of skilled labor and equipment can impact the size and shape restrictions of concrete structures formed with steel frame formwork. If there is a shortage of experienced workers or appropriate equipment on the construction site, handling and assembling the formwork for larger or more complex structures can become problematic. To ensure successful implementation of steel frame formwork, it is crucial to consider these limitations during the design and planning stages of a construction project. By taking these factors into account, one can effectively utilize the flexibility offered by steel frame formwork while mitigating the constraints associated with height, shape complexity, panel size, and the availability of skilled labor and equipment.

Send your message to us

different kinds of plastic formworks used in construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches