Plastic Formworks in Different Kinds of Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of plastic formworks

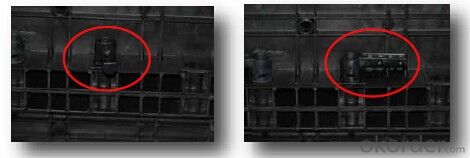

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

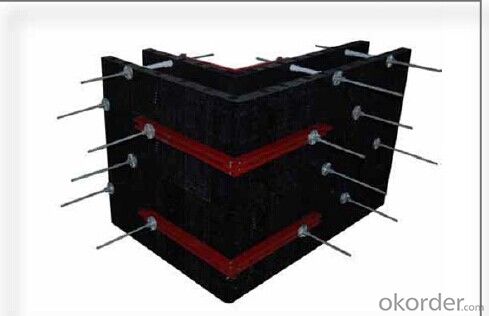

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of plastic formworks

-Light weight

-High strength

-High standardized system

-Easy connection with adjustable steel clamp

-Convenient and fast corner formwork

-Flexible to assemble and application

3. plastic formworks Images

4. plastic formworks Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of plastic formworks

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formworks, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. plastic formworks cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of plastic formworks, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Does steel frame formwork require any specific reinforcement detailing?

- Yes, steel frame formwork does require specific reinforcement detailing. The reinforcement detailing is necessary to ensure the structural integrity and stability of the formwork system, especially during the pouring and curing of concrete. The reinforcement detailing includes the placement and spacing of steel bars, the size and type of reinforcement elements, and the connections between different components of the formwork system. Proper reinforcement detailing helps to distribute loads evenly, prevent potential cracks or failures, and enhance the longevity of the formwork.

- Q: What are the components of a steel frame formwork system?

- The components of a steel frame formwork system typically include steel frames, cross braces, adjustable jacks, formwork panels, and assorted accessories such as wedge pins, tie rods, and form aligners.

- Q: How does steel frame formwork help in achieving a high-quality concrete finish?

- By using steel frame formwork, a stable and rigid structure is created to pour and shape the concrete, resulting in a high-quality finish. The steel frames are designed to withstand the pressure of the wet concrete, ensuring that the formwork remains intact and does not collapse. This leads to a smooth and even concrete surface. Moreover, the steel frame formwork allows for precise placement of the concrete. The frames are adjustable, making it easy to customize them according to the project requirements. This flexibility ensures that the concrete is poured exactly where it should be, minimizing the possibility of imperfections or inconsistencies. Additionally, the steel frame formwork provides excellent support for reinforcing materials like rebar. The rigid structure of the frames keeps the reinforcing materials in place, preventing them from shifting or sinking during the pouring process. This guarantees that the concrete is reinforced properly, resulting in a stronger and more durable end product. Furthermore, the steel frame formwork facilitates efficient and consistent concrete curing. The frames often have built-in channels or holes for the insertion of curing agents like water or chemicals. This enables the concrete to cure evenly and thoroughly, enhancing its strength and durability. In conclusion, steel frame formwork is essential in achieving a high-quality concrete finish. It provides stability, precision, and support during the pouring and shaping process. Its durability, adjustability, and ability to facilitate efficient curing contribute to the overall quality and longevity of the concrete structure.

- Q: How does steel frame formwork accommodate for different concrete test requirements?

- The versatility and adaptability of steel frame formwork make it an ideal system for accommodating different concrete test requirements. This is primarily due to its modular design and adjustable components. To begin with, steel frame formwork allows for the construction of concrete structures in various shapes and sizes. The steel frames can be easily assembled and disassembled to create different configurations, providing flexibility in meeting different concrete test requirements. Whether it is a simple slab or a complex column or wall, the steel formwork can be adjusted to fit the specific dimensions and design needs. Additionally, the adjustable components of the steel frame formwork enable the customization of concrete test requirements. The formwork system includes adjustable vertical and horizontal supports, as well as adjustable brackets and props. These components can be easily moved, adjusted, and aligned to accommodate different concrete test requirements, such as varying heights, thicknesses, or angles. Moreover, the steel frame formwork offers the flexibility to incorporate various form liners, inserts, or accessories based on specific concrete test requirements. These may include inserts for creating specific surface finishes, form liners for decorative patterns, or additional accessories for reinforcing or strengthening the concrete structure. The steel formwork system can be tailored and modified to include these elements, ensuring the fulfillment of concrete test requirements. In conclusion, steel frame formwork is an adaptable system that readily adjusts to different concrete test requirements. Its modular nature, adjustable components, and ability to incorporate various accessories make it a versatile choice for a wide range of construction projects.

- Q: Are there any specific design codes or standards that govern the use of steel frame formwork?

- Steel frame formwork is governed by specific design codes and standards. One well-known standard is the American Concrete Institute (ACI) 347-04, which provides guidelines for the design, construction, and use of formwork systems, including steel frame formwork, for concrete structures. In addition to ACI 347-04, there are other international standards and codes that may apply depending on the location and project requirements. For instance, the European Standard EN 12812:2008 provides guidelines for the design, performance, and use of falsework systems, which includes steel frame formwork. These codes and standards cover various aspects such as design criteria, material requirements, safety considerations, and construction practices. Their purpose is to ensure that steel frame formwork systems are structurally sound, safe, and capable of withstanding the loads and pressures exerted by the concrete during pouring and curing. Stability, bracing, tie spacing, and formwork accessories are also addressed by these design codes and standards to ensure the proper functioning of the steel frame formwork system. They also require the implementation of safety measures such as guardrails, handrails, and access platforms to protect workers during formwork assembly, use, and removal. Compliance with these codes and standards is essential to maintain the integrity of the structure, ensure worker safety, and successfully complete concrete construction projects. Architects, engineers, contractors, and formwork manufacturers must adhere to these guidelines and incorporate them into their design and construction processes when utilizing steel frame formwork.

- Q: Can steel frame formwork be used for concrete stairs?

- Yes, steel frame formwork can be used for concrete stairs. Steel frame formwork is a versatile and durable system that can be customized to suit various construction needs, including the construction of stairs. It offers several advantages for constructing concrete stairs, such as high strength, stability, and the ability to create complex shapes and designs. Steel frame formwork provides a reliable and efficient solution for constructing concrete stairs, ensuring a strong and long-lasting structure.

- Q: Can steel frame formwork be used for both above-ground and below-ground concrete elements?

- Yes, steel frame formwork can be used for both above-ground and below-ground concrete elements. Steel frame formwork is versatile and can be easily customized to suit various project requirements. Its durability and strength make it suitable for both above-ground structures like beams, columns, and slabs, as well as below-ground elements like basements, foundation walls, and retaining walls.

- Q: Can steel frame formwork be used for the construction of educational facilities?

- Yes, steel frame formwork can be used for the construction of educational facilities. Steel frame formwork is a versatile and durable system that provides a strong support structure for concrete during the construction process. Its strength and stability make it suitable for constructing various types of buildings, including educational facilities. One of the main advantages of steel frame formwork is its ability to withstand heavy loads and provide a safe working environment. This is particularly important for educational facilities, as they often accommodate a large number of people and require strong and durable structures to ensure the safety of students and staff. Additionally, steel frame formwork allows for flexibility in design and construction. It can be easily adjusted and customized to meet the specific requirements of educational facilities, such as the layout of classrooms, laboratories, and other specialized areas. This flexibility enables architects and engineers to create functional and efficient spaces that cater to the needs of students and educators. Furthermore, steel frame formwork is highly reusable and cost-effective. It can be dismantled and used multiple times for different construction projects, reducing waste and saving resources. This makes it an environmentally friendly choice for educational facilities, which often strive to promote sustainability and responsible construction practices. In conclusion, steel frame formwork is a suitable option for the construction of educational facilities due to its strength, stability, flexibility, and cost-effectiveness. Its ability to withstand heavy loads, provide a safe working environment, and be customized to meet specific requirements makes it an ideal choice for creating functional and efficient learning spaces.

- Q: What is the meaning of steel frame support structure?What is the support?

- The so-called steel structure is the support, the traditional way of reinforced concrete as a support, the steel structure is the use of H steel as a support

- Q: How does steel frame formwork affect the overall fire resistance of a building?

- Steel frame formwork can have a significant impact on the overall fire resistance of a building. Steel is a strong and durable material that can withstand high temperatures for a longer period compared to other construction materials such as wood or concrete. This means that steel frame formwork can provide a higher level of fire resistance and structural integrity during a fire incident. The steel frame formwork acts as a protective barrier, preventing the fire from spreading rapidly throughout the building. It can also help in minimizing the damage caused by the fire as it can maintain its structural stability under extreme heat conditions. This is crucial in ensuring the safety of occupants and allowing them more time to evacuate the building. Moreover, steel frame formwork can enhance the fire resistance of other components of the building, such as floors, walls, and ceilings. By using steel formwork, these components can be reinforced and made more resistant to fire, thus increasing the overall fire performance of the building. However, it is important to note that the fire resistance of a building is not solely dependent on the steel frame formwork. Other factors such as the fire protection measures, insulation materials, and the overall design of the building also play a crucial role in determining the fire resistance rating. Therefore, it is essential to ensure that all these factors are carefully considered and integrated into the building design to achieve optimal fire safety.

Send your message to us

Plastic Formworks in Different Kinds of Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords