Tool Steel Cold Rolled 1.2379 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

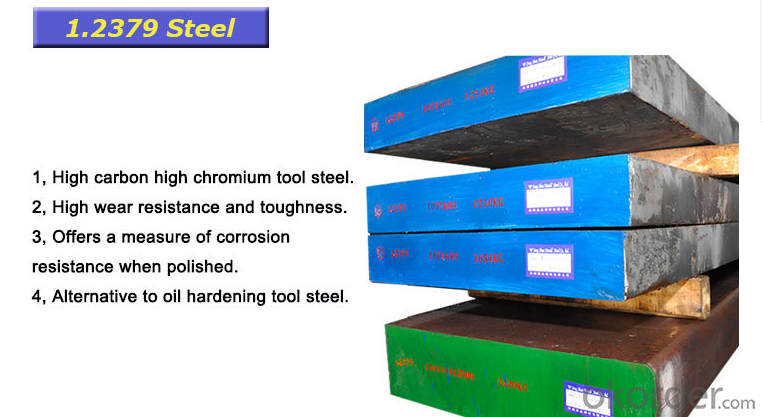

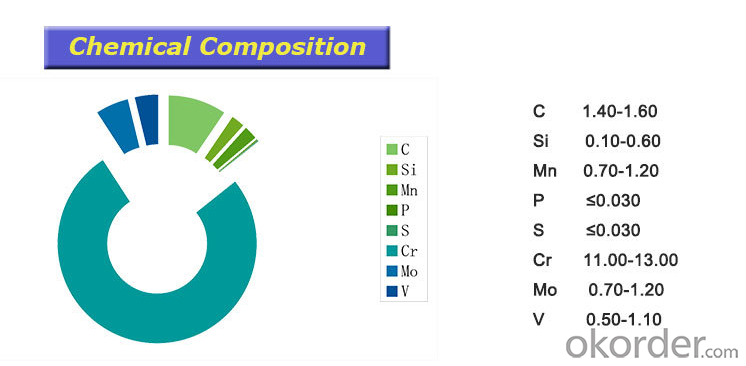

Tool Steel Cold Rolled 1.2379 Steel Bar r

Product information:

Specifications

Hot Selling Tool Steel Cold Rolled 1.2379 Steel Bar Prices

1.A/N/Q+T

2.Sample free

3.Black or Bright

4.T Max:800mm

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does special steel perform in high-pressure applications?

- Special steel performs exceptionally well in high-pressure applications. This type of steel is specifically designed to withstand extreme pressure conditions, making it an ideal choice for industries that require reliable and durable materials for their operations. One of the key characteristics of special steel is its high tensile strength, which allows it to handle immense pressure without deformation or failure. This strength is achieved through alloying elements and heat treatment processes that enhance the steel's structural integrity. As a result, special steel can withstand the intense forces exerted on it in high-pressure environments, ensuring the safety and efficiency of the equipment or structures it is used in. Furthermore, special steel exhibits excellent resistance to corrosion and oxidation, further enhancing its suitability for high-pressure applications. This resistance helps maintain the structural integrity of the steel, preventing any weakening or degradation that could compromise its performance under pressure. Additionally, special steel's resistance to corrosion ensures that it can withstand harsh environments, such as those found in oil and gas extraction, chemical processing, or power generation industries. Another advantage of special steel in high-pressure applications is its ability to retain its mechanical properties even at elevated temperatures. This property is crucial in industries where high temperatures are involved, such as aerospace, nuclear power, or steam generation. The steel's high-temperature strength and stability enable it to withstand the combination of high pressure and elevated temperatures, ensuring reliable performance and long-term durability. In summary, special steel is an excellent choice for high-pressure applications due to its high tensile strength, resistance to corrosion and oxidation, as well as its ability to maintain its mechanical properties at elevated temperatures. Its exceptional performance in these demanding conditions makes it a reliable and durable material for industries that operate under high-pressure environments.

- Q: What are the different shapes and forms in which special steel is available?

- Special steel is available in various shapes and forms such as bars, rods, sheets, plates, tubes, pipes, wires, and forgings.

- Q: Can special steel be used for cutting tools?

- Yes, special steel can be used for cutting tools. Special steels, such as high-speed steel or tool steel, are specifically designed to have superior hardness, toughness, and wear resistance, making them ideal for manufacturing cutting tools that can withstand high temperatures and perform precision cutting operations.

- Q: What are the unique properties of stainless steel?

- Stainless steel has several unique properties that make it highly desirable in various applications. Firstly, it has excellent corrosion resistance, making it resistant to rust and staining, even in harsh environments. Additionally, stainless steel is durable and can withstand high temperatures, making it suitable for use in extreme conditions. It also has a high strength-to-weight ratio, making it strong yet lightweight. Moreover, stainless steel is hygienic and easy to clean, making it ideal for use in food processing and medical equipment. Lastly, stainless steel has an attractive appearance and can be easily fabricated into different shapes, making it a versatile material for various industries.

- Q: How does special steel withstand high temperatures?

- Due to its distinctive composition and manufacturing process, special steel demonstrates exceptional resistance to high temperatures. Firstly, special steel incorporates alloys that consist of elements like chromium, nickel, and molybdenum, thus providing heightened heat resistance. These elements form a protective oxide layer on the steel's surface, effectively preventing oxidation and corrosion when exposed to elevated temperatures. Moreover, special steel undergoes specific heat treatment procedures, such as quenching and tempering, which enhance its strength and toughness. These procedures involve subjecting the steel to high temperatures followed by rapid cooling, and then reheating and slow cooling. This controlled heating and cooling process alters the steel's microstructure, resulting in increased resistance to thermal stress and deformation. Additionally, special steel is often designed with a high melting point, enabling it to maintain its structural integrity even in extreme temperature conditions. The precise combination and proportions of elements in the alloy contribute to the steel's ability to resist softening or melting when confronted with intense heat. Furthermore, special steel may also incorporate specialized coatings or treatments that further enhance its thermal resistance. These coatings provide an additional layer of protection against heat, oxidation, and corrosion, thereby enhancing the steel's durability and longevity in high-temperature environments. To sum up, special steel's ability to withstand high temperatures is attributed to its unique alloy composition, heat treatment processes, high melting point, and additional protective coatings. These factors work in harmony to enhance the steel's resistance to thermal stress, deformation, oxidation, and corrosion, making it a dependable and durable material for applications in extreme heat conditions.

- Q: What are the common grades of special steel?

- The common grades of special steel include stainless steel grades such as 304, 316, and 430, as well as tool steel grades like D2, A2, and O1. Other common grades include high-speed steel (HSS), alloy steel grades like 4140 and 4340, and maraging steel grades such as 250 and 300.

- Q: What are the different types of precipitation-hardening steel?

- There are several types of precipitation-hardening steel, including 17-4 PH, 15-5 PH, 13-8 PH, and 17-7 PH. These steels are known for their high strength and corrosion resistance, making them suitable for various applications in industries such as aerospace, automotive, and medical.

- Q: What are some examples of special steel alloys?

- Some examples of special steel alloys include stainless steel, tool steel, high-speed steel, alloy steel, and maraging steel.

- Q: What are the different standards and specifications for special steel?

- There are several standards and specifications for special steel, which vary depending on the specific type and application of the steel. Some common standards include AISI (American Iron and Steel Institute), ASTM (American Society for Testing and Materials), EN (European Norm), and JIS (Japanese Industrial Standards). These standards define the chemical composition, mechanical properties, and manufacturing processes required for special steel to meet certain quality and performance standards. Additionally, there may be specific specifications for different industries or applications, such as aerospace, automotive, or construction, that further define the requirements for special steel.

- Q: What are the casting methods for special steel?

- There are several casting methods used for special steel, including the traditional sand casting method, investment casting, and continuous casting. Each method has its own advantages and is chosen based on factors such as the complexity of the steel shape, desired surface finish, and production volume.

Send your message to us

Tool Steel Cold Rolled 1.2379 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords