Cold Work Alloy Tool Steel Round Bars 1.2379

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Work Alloy Tool Steel Round Bars 1.2379

Details Information of Cold Work Alloy Tool Steel Round Bars 1.2379

| Name | Cold Work Alloy Tool Steel Round Bars 1.2379 |

| Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

| Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

| Surface Treatment: | Black/Peeling/Polished/Machined |

| Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

| Test | SGS/UT 100% Elements Testing |

| Certificate: | ISO/Mill Certificate |

| Service: | 24 hours online service / |

| more than 20 years trading and manufacture | |

| Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

| Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

| Carbon structure round bar | Q195 Q235A Q235B 10# 20#-55# S45CB |

| Low alloy high strength round bar | Q345A/Q345C/Q345D Q345B Q345E |

| Alloy structure round bar | SAE51B20 20Cr 40Cr 40CrV 20CrMo/30CrMo/35CrMo/42CrMo 20CrMoA/30CrMoA/35CrMoA/42CrMoA/42Cr ML20CrMo/ML30CrMo/ML35CrMo/ML42CrMo B7/SCM435-440 20MnTiB 20CrMnMo 20CrMoH 42CrMoH 40MnB/40MnBH 30Mn2-40Mn2 27SiMn 50CrVA 30CrMnTi |

| Pinion steel | 20CrMnTi 20CrMnTiH 20CrMnTiHCS/20CrMnTiHLD Q20CrMnTi-1/Q20CrMnTi-2 |

| Sucker rod | 20-35CrMoA |

| Free-cutting steel | GT1215S |

| Spring steel | 60Si2MnA 65Mn |

| Ball bearing steel | GCr15 |

Chemical Composition of Cold Work Alloy Tool Steel Round Bars 1.2379

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

| Tensile strength (σb/MPa) | Yield strength (σb/MPa) | Elongation (δ5/%) |

| ≥410(42) | ≥245(25) | ≥25 |

Company Introduction of Cold Work Alloy Tool Steel Round Bars 1.2379

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Certificates of Cold Work Alloy Tool Steel Round Bars 1.2379

Packaging & Delivery of Cold Work Alloy Tool Steel Round Bars 1.2379

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

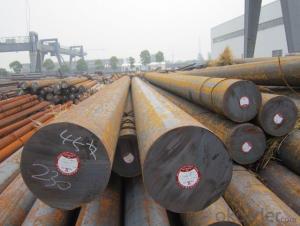

Products show of Cold Work Alloy Tool Steel Round Bars 1.2379

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different techniques used for joining special steel?

- Some of the different techniques used for joining special steel include welding, brazing, soldering, and mechanical fastening. Welding involves melting the surfaces of the steel pieces to be joined and fusing them together. Brazing and soldering involve using a filler material that melts at a lower temperature than the steel to join the pieces together. Mechanical fastening techniques, such as bolts, screws, or rivets, can also be used to join special steel components together.

- Q: How is special steel used in the packaging supply chain?

- Special steel is used in the packaging supply chain for various purposes such as manufacturing machinery, tools, and equipment needed for packaging processes. It is used to create durable and reliable components like blades, cutters, and molds, ensuring precise and efficient packaging operations. Additionally, special steel can be utilized for constructing robust packaging materials like containers, pallets, and racks, providing strength and stability during transportation and storage.

- Q: How does special steel perform in dynamic loading conditions?

- Special steel performs well in dynamic loading conditions due to its high strength, toughness, and fatigue resistance. When subjected to dynamic loads, which involve repeated and fluctuating stresses, special steel can withstand the impact and retain its mechanical properties without failure or deformation. The unique composition and processing of special steel, such as alloying elements and heat treatment, enhance its ability to resist dynamic loading. This makes it an ideal material for applications that involve dynamic forces, such as automotive components, machinery parts, and structural elements in construction. Special steel's exceptional performance in dynamic loading conditions ensures durability, reliability, and safety in various industries.

- Q: What are the advantages of using special steel over other materials?

- There are several advantages of using special steel over other materials. Firstly, special steel offers superior strength and durability, making it ideal for applications that require high load-bearing capacity or resistance to wear and tear. Secondly, special steel has excellent corrosion resistance properties, which is particularly important for industries such as construction, automotive, and marine. Additionally, special steel can be easily customized and shaped to meet specific design requirements, providing flexibility in manufacturing processes. Lastly, special steel often exhibits high heat resistance and excellent mechanical properties, making it suitable for demanding environments and critical applications.

- Q: What is the maximum temperature that special steel can withstand?

- The maximum temperature that special steel can withstand depends on the specific type and composition of the steel. However, special steels are designed to have high heat resistance and can typically withstand temperatures ranging from 800 to 1200 degrees Celsius.

- Q: How does special steel contribute to the automotive material recycling?

- Special steel plays a significant role in automotive material recycling by providing high-strength and durable components that can be easily disassembled and reused. Its properties allow for effective recycling processes, enabling the extraction of valuable materials from end-of-life vehicles. This contributes to the sustainability of the automotive industry by reducing waste and conserving resources.

- Q: How does special steel contribute to the manufacturing of defense equipment?

- Special steel plays a crucial role in the manufacturing of defense equipment due to its exceptional properties. It provides enhanced strength, durability, and resistance to extreme conditions, making it ideal for critical components such as armor plates, missile casings, or aircraft parts. Special steel's ability to withstand high temperatures, impacts, and corrosion ensures the reliability and longevity of defense equipment, ultimately enhancing the safety and effectiveness of military operations.

- Q: How is alloy steel different from carbon steel?

- Alloy steel differs from carbon steel in that it contains additional elements, such as nickel, chromium, or molybdenum, which enhance its strength, hardness, and corrosion resistance. This makes alloy steel more suitable for applications that require high performance and durability, while carbon steel is typically used for general-purpose applications.

- Q: What are the different methods for joining special steel?

- There are several methods for joining special steel, including welding, brazing, soldering, and mechanical fastening. Welding involves melting the steel pieces together using heat and filling the gap with a molten filler material. Brazing uses a lower melting point filler material to join the steel pieces together. Soldering is a similar process to brazing but uses an even lower melting point filler material. Mechanical fastening includes methods such as bolting, riveting, or using adhesives to hold the steel pieces together.

- Q: What is the purpose of cold drawing in special steel production?

- The purpose of cold drawing in special steel production is to improve the mechanical properties and dimensional accuracy of the steel. Cold drawing involves pulling the steel through a die at room temperature, which reduces the cross-sectional area and increases the length of the steel. This process helps to refine the microstructure of the steel, resulting in improved strength, hardness, and toughness. Additionally, cold drawing can enhance the surface finish and straightness of the steel, ensuring precise dimensions and making it suitable for various applications where high-quality steel is required. Overall, cold drawing plays a crucial role in enhancing the performance and quality of special steel, making it more reliable and efficient in various industrial sectors.

Send your message to us

Cold Work Alloy Tool Steel Round Bars 1.2379

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords