Flat Spring Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 600000/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spring Steel can be divided into two types. One is carbon spring steel, and other one is alloy spring steel.

Alloy spring steel is based on carbon spring steel, by adding one or more alloying elements to improve the mechanical properties, hardenability and other properties to meet the requirement for manufacturing all kinds of spring steel.

Specification of Flat Spring Steel:

-Material: 55Si2Mn

-Production: Hot rolled or cold rolled

-Standard: GB/T 1222-1984

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Si | Mn | S |

0.52~0.6 | 1.500~2.00 | 0.60~0.90 | ≤0.035 |

P | Cr | Ni | Cu |

≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

Usage/Applications of Flat Spring Steel:

-Elements Si and Mn improve elasticity strength, hardenability, and the ratio of yield point and tensile strength. but the decarburization tendency is a little large,

-55Si2Mn Spring Steel can be used as vibration damper leaf spring and spiral spring of cars and tractors.

-Heat-resisting spring below 250 degrees.

Packaging & Delivery of Flat Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

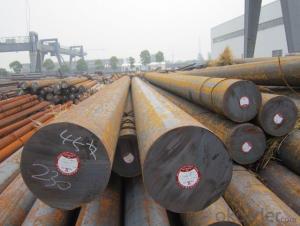

Photos of Flat Spring Steel:

- Q: What are the main applications of special steel in the marine sector?

- Special steel is widely used in the marine sector for various applications. Some of the main applications include the construction of ship hulls, offshore platforms, and marine structures. Special steel's high strength, corrosion resistance, and durability make it suitable for withstanding harsh marine environments. Additionally, special steel is used in propeller shafts, rudders, and other critical components, ensuring efficient and reliable performance of marine vessels.

- Q: How is special steel used in the production of consumer goods?

- Special steel is used in the production of consumer goods due to its exceptional strength, durability, and corrosion resistance. It is commonly employed in the manufacturing of kitchen appliances, cutlery, automotive parts, and electronics, ensuring high-quality and long-lasting products for consumers.

- Q: What are the main factors affecting the impact toughness of special steel?

- The main factors affecting the impact toughness of special steel include the chemical composition of the steel, the microstructure and grain size, the heat treatment process, and the presence of impurities or defects in the material. Additionally, the manufacturing process, such as forging or rolling, can also impact the impact toughness of special steel.

- Q: What are the different methods of preventing stress relaxation in special steel?

- Preventing stress relaxation in special steel can be achieved through various methods. One effective approach is the utilization of heat treatment, specifically by employing the annealing process. Annealing consists of heating the steel to a specific temperature and gradually cooling it down. This technique successfully alleviates internal stresses within the steel, thus preventing stress relaxation. Another effective method involves employing stress relieving techniques. These techniques necessitate the controlled application of stress to the steel, typically through cold working or mechanical deformation. By doing so, the steel can effectively release any accumulated stress and avoid relaxation over time. Furthermore, incorporating alloying elements into the steel can also aid in preventing stress relaxation. Certain alloying elements, such as molybdenum and chromium, enhance the steel's strength and stability, thereby improving its resistance to stress relaxation. Lastly, meticulous design and engineering of components also contribute to the prevention of stress relaxation. Engineers can minimize the risk of stress relaxation in special steel applications by considering factors such as load distribution, material thickness, and stress concentration points. In conclusion, a combination of heat treatment, stress relieving techniques, alloying elements, and thoughtful design can be employed to effectively prevent stress relaxation in special steel.

- Q: How is the toughness of special steel measured?

- The toughness of special steel can be assessed by specific tests and methodologies that evaluate its capacity to absorb energy and withstand fractures. One widely used approach is the Charpy V-Notch (CVN) test, in which a notched specimen is struck by a pendulum hammer, and the energy absorbed during fracture is measured. The results are then expressed as the energy absorbed per unit area, typically in joules per square centimeter (J/cm²) or foot-pounds per square inch (ft-lb/in²). Another commonly employed test is the Izod test, which is similar to the CVN test but involves a different specimen geometry. Furthermore, engineers and manufacturers may also employ other mechanical tests such as tensile strength, impact strength, and fracture toughness measurements to evaluate the toughness of special steel. These tests are invaluable in determining the suitability of special steel for various applications, particularly those requiring exceptional resistance to impact or sudden loading.

- Q: How does molybdenum improve the performance of special steel?

- Due to its unique properties and characteristics, molybdenum is crucial in enhancing the performance of special steel. Its role is multi-faceted and includes improving strength and toughness, increasing hardenability, enhancing corrosion resistance, and improving high-temperature strength and creep resistance. One of the primary benefits of molybdenum is its ability to significantly improve the strength and toughness of steel, making it more durable and resistant to deformation. This is achieved by forming a solid solution with iron, resulting in a fine-grained microstructure and reducing the formation of brittle phases in the steel. Another advantage of molybdenum is its impact on the hardenability of steel. It allows the steel to be heat-treated to achieve the desired mechanical properties. This is particularly important in the production of special steel, where high strength, wear resistance, and thermal stability are often required. By enabling effective heat treatment, molybdenum ensures that the steel can be processed to meet specific performance requirements, such as hardness, toughness, and dimensional stability. Moreover, molybdenum enhances the corrosion resistance of special steel, making it suitable for challenging environments. It forms a protective oxide layer on the steel's surface, acting as a barrier against corrosive substances like acids, alkalis, and salts. This corrosion resistance is crucial in applications where the steel is exposed to harsh conditions, such as marine environments, chemical processing plants, and oil and gas industries. Furthermore, molybdenum improves the high-temperature strength and creep resistance of special steel. It enables the steel to maintain its mechanical properties even at elevated temperatures, making it suitable for applications where the steel is subject to prolonged exposure to heat or mechanical stress. In conclusion, molybdenum plays a vital role in enhancing the performance of special steel by improving its strength, toughness, hardenability, corrosion resistance, and high-temperature properties. These attributes make molybdenum an essential alloying element in the production of special steel for various industries, including automotive, aerospace, energy, and tool manufacturing.

- Q: What are the physical properties of special steel?

- Compared to regular steel, special steel possesses unique physical properties. These properties can vary depending on the specific composition and processing techniques employed. However, special steel typically exhibits high strength, hardness, and durability. Its design often aims to withstand extreme conditions, including high temperatures, pressure, and corrosive environments. Additionally, special steel may display exceptional wear resistance, making it suitable for applications involving heavy machinery or cutting tools. Moreover, it can possess superior electrical and thermal conductivity, along with favorable magnetic properties. In conclusion, the physical properties of special steel render it highly versatile and valuable across various industries, such as automotive, aerospace, construction, and energy.

- Q: What are the different carburizing techniques used for special steel?

- There are several carburizing techniques used for special steel, including pack carburizing, gas carburizing, and vacuum carburizing. Pack carburizing involves placing the steel in a container with a carbon-rich material, such as charcoal or coke, and heating it to high temperatures. Gas carburizing involves introducing a carbon-rich gas, such as methane or propane, into a furnace where the steel is heated. Vacuum carburizing utilizes a low-pressure atmosphere to introduce carbon into the steel at high temperatures. Each technique has its own advantages and is chosen based on factors such as desired depth of carburization, time constraints, and the type of steel being treated.

- Q: How does special steel perform in terms of hardness?

- Special steel typically performs very well in terms of hardness. It has a higher hardness level compared to regular steel due to the addition of various alloying elements during its production. This enhanced hardness allows special steel to withstand wear, abrasion, and deformation better than other types of steel. It also enables special steel to be suitable for specialized applications that require high strength and resistance to impact or pressure.

- Q: How is wear-resistant steel used in mining equipment?

- Wear-resistant steel is commonly used in mining equipment to increase its durability and prolong its lifespan. It is utilized in various components such as buckets, blades, and hammers, which are subjected to intense abrasion and impact during mining operations. By incorporating wear-resistant steel, these equipment parts can withstand the harsh conditions and abrasive materials encountered in mining, reducing the need for frequent repairs or replacements and ensuring continuous productivity.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Asia-Pacific; Middle east |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai. |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Flat Spring Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 600000/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords