AISI 52100 Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AISI 52100 Bearing Steel

1. Standard:

CHINA | ISO | U.S.A. | GERMANY | JAPAN | SWENDEN | FRANCE |

Gcr15 | 683/XVII | 52100(AISI) | 100Cr6(DIN) | SUJ2(JIS) | SKF3 | 100C6(NF) |

2. Dimensions: Diameter 80-1000mm,or as required; Length 500-6000mm,or as required;

3. Processing conditions:

Annealing: Heating to 790-810°C, furnace cool to 650°C, then cool in air |

Normalized: Heating to 900-920°C, cool in air |

High Temperature Tempered: Heating to 650-800°C, cool in air |

Quenched: Heating to 860°C, oil quenched |

Low Temperature Tempered: Heating to 150-170°C, cool in air |

4. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

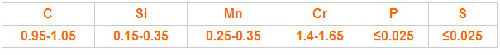

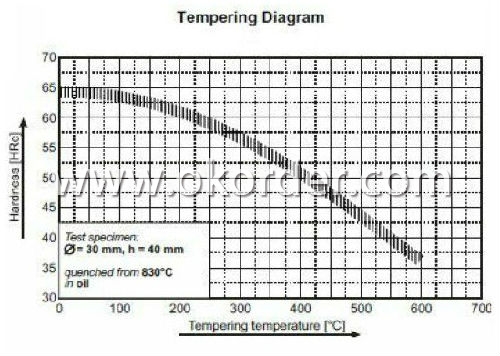

5. Chemical Composition

6.Tempering Diagram

.

7. Payment terms: T/T or L/C at sight

Usage & Applications of AISI 52100 Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of AISI 52100 Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm),

and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

- Q: Is special steel resistant to wear and abrasion?

- Indeed, special steel is renowned for its exceptional resistance against wear and abrasion. Through the utilization of distinct alloying elements and heat treatment procedures, special steel is frequently crafted to elevate its hardness and toughness. These remarkable attributes confer upon it a remarkable immunity to the damaging consequences of wear and abrasion, rendering it ideal for endeavors necessitating longevity and durability. In various industries, including automotive, aerospace, construction, and manufacturing, special steels are frequently employed due to the harsh environments they encounter or the repetitive mechanical actions they endure, both of which can induce wear and abrasion.

- Q: What is the role of special steel in the defense industry?

- The unique properties and capabilities of special steel are critical to the defense industry. Its primary function is to provide strength and durability to military equipment, including tanks, armored vehicles, naval vessels, and aircraft. These steels are designed to withstand extreme conditions such as high impact and ballistic resistance, ensuring the safety and protection of military personnel. Special steel also plays a significant role in the production of cutting-edge weaponry. It is used to manufacture firearms, missiles, and artillery systems, offering the necessary strength, hardness, and corrosion resistance. These steels allow for the precise manufacturing of complex weapon systems, ultimately improving their performance, accuracy, and reliability. Additionally, special steel contributes to the development of advanced communication and electronics technologies. Steel alloys with specific magnetic properties are utilized in the production of radar systems, satellite components, and other electronic devices crucial for military surveillance, intelligence, and communication purposes. These steels enable efficient signal transmission and reception, enhancing the overall capabilities of defense systems. In conclusion, special steel is indispensable in the defense industry due to its unique properties and capabilities. It serves as the foundation for military equipment, enhances the performance of weapons, and enables the development of advanced communication and electronics technologies. By utilizing special steel, the defense industry ensures the safety, effectiveness, and technological superiority of military operations.

- Q: What are the different types of alloy steel?

- There are several different types of alloy steel, including stainless steel, tool steel, maraging steel, high-strength low-alloy steel (HSLA), and nickel-based alloy steel.

- Q: How does special steel perform in forging applications?

- Special steel is highly desirable for forging applications due to its exceptional strength, durability, and resistance to wear and tear. It offers superior performance as it can withstand the intense heat and pressure involved in the forging process without losing its shape or integrity. Additionally, special steel's unique composition allows for precise shaping and intricate designs, making it an ideal choice for complex forging projects.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel offers several advantages in the automotive industry. Firstly, it provides enhanced strength and durability, ensuring the safety and reliability of vehicles. Secondly, special steel is lightweight, contributing to fuel efficiency and reducing carbon emissions. Additionally, it offers excellent formability and weldability, allowing for complex and intricate designs. Lastly, special steel possesses high corrosion resistance, extending the lifespan of automotive components and reducing maintenance costs. Overall, the use of special steel in the automotive industry enhances performance, efficiency, safety, and longevity.

- Q: How does special steel perform in erosion applications?

- Special steel performs exceptionally well in erosion applications due to its high resistance to wear and corrosion. Its unique composition and enhanced durability make it an ideal choice for environments where erosion is a common concern. Special steel's ability to withstand abrasive forces and maintain its structural integrity over time ensures long-lasting performance and minimizes the need for frequent replacements or repairs.

- Q: How does special steel perform in corrosive environments?

- The purpose of special steel is to excel in corrosive environments. This is achieved by incorporating a greater amount of alloying elements, like chromium, which generates a safeguarding oxide layer on the steel's surface. By doing so, the steel is shielded from direct contact with the corrosive elements present in the environment. In addition, special steel may contain other alloying elements such as molybdenum, nickel, or copper, which further enhance its ability to resist corrosion. These elements contribute to the steel's capacity to withstand various types of corrosion, including pitting, crevice corrosion, and stress corrosion cracking, which are commonly observed in corrosive environments. Moreover, special steel often undergoes treatments with diverse surface coatings or finishes that offer additional defense against corrosion. These coatings encompass materials like zinc, epoxy, or polymers, which establish an extra barrier between the steel and the corrosive elements. To summarize, special steel delivers exceptional performance in corrosive environments due to its abundant alloying elements, protective oxide layer, and supplementary surface coatings. It provides remarkable resistance against different forms of corrosion and guarantees the durability and dependability of structures or equipment operating in such environments.

- Q: How is high-speed tool steel used in the production of machining tools?

- High-speed tool steel is used in the production of machining tools due to its exceptional hardness, strength, and heat resistance properties. It is commonly used to make cutting tools such as drills, end mills, taps, and inserts, which are vital for precision machining operations. The high-speed tool steel's ability to retain its hardness even at high temperatures allows these tools to withstand the intense heat generated during the machining process, resulting in improved performance and extended tool life.

- Q: How is wear-resistant steel used in mining equipment?

- Wear-resistant steel is commonly used in mining equipment to enhance their durability and longevity. It is specifically designed to withstand the harsh conditions and abrasive environments typically found in mining operations. Components such as buckets, blades, chutes, crushers, and screens are often made from wear-resistant steel to prevent excessive wear and damage caused by rocks, minerals, and other abrasive materials. This steel's high hardness and toughness properties ensure that the equipment can withstand the constant impact and abrasion, reducing maintenance needs and extending the equipment's lifespan.

- Q: How does special steel perform in nuclear applications?

- Due to its exceptional properties and performance, special steel holds significant value in nuclear applications. Nuclear reactors operate under extreme conditions, enduring high temperatures, pressures, and radiation exposure. Designed specifically for these demanding circumstances, special steel, also known as nuclear-grade steel or reactor-grade steel, can withstand them. One of the primary characteristics of special steel lies in its remarkable strength and toughness. This quality enables it to resist deformation and fractures, even under the intense stress and pressure present in nuclear reactors. Additionally, special steel exhibits superior heat resistance, ensuring its structural integrity remains intact at elevated temperatures. This feature is critical to prevent any potential failures or structural damage that could jeopardize the safety and efficiency of the nuclear system. Moreover, special steel possesses exceptional resistance to corrosion and oxidation. The highly corrosive environments within nuclear reactors, caused by various chemical compounds and high-temperature water or steam, make this corrosion resistance indispensable. It ensures the longevity and reliability of reactor components while minimizing the risk of radioactive material release. Furthermore, special steel is designed to have low neutron absorption properties. By reducing neutron absorption, special steel helps optimize the performance and efficiency of the nuclear system. This is vital as neutron absorption can lead to the formation of unwanted isotopes that could interfere with nuclear reactions or contribute to the production of radioactive waste. Overall, special steel is a critical material in nuclear applications. Its provision of necessary strength, heat resistance, corrosion resistance, and low neutron absorption ensures the safe and efficient operation of nuclear reactors. Its exceptional performance guarantees the integrity of the system, minimizes accident risks, and contributes to the overall sustainability of nuclear energy.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

AISI 52100 Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords