Hot Work Tool Steel Round Bar Grade 1.2344

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Work Tool Steel Round Bar Grade 1.2344

Details Information of Hot Work Tool Steel Round Bar Grade 1.2344

| Name | Grade 1.2344 Steel Round Bar |

| Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

| Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

| Surface Treatment: | Black/Peeling/Polished/Machined |

| Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

| Test | SGS/UT 100% Elements Testing |

| Certificate: | ISO/Mill Certificate |

| Service: | 24 hours online service / |

| more than 20 years trading and manufacture | |

| Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

| Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

| Carbon structure round bar | Q195 Q235A Q235B 10# 20#-55# S45CB |

| Low alloy high strength round bar | Q345A/Q345C/Q345D Q345B Q345E |

| Alloy structure round bar | SAE51B20 20Cr 40Cr 40CrV 20CrMo/30CrMo/35CrMo/42CrMo 20CrMoA/30CrMoA/35CrMoA/42CrMoA/42Cr ML20CrMo/ML30CrMo/ML35CrMo/ML42CrMo B7/SCM435-440 20MnTiB 20CrMnMo 20CrMoH 42CrMoH 40MnB/40MnBH 30Mn2-40Mn2 27SiMn 50CrVA 30CrMnTi |

| Pinion steel | 20CrMnTi 20CrMnTiH 20CrMnTiHCS/20CrMnTiHLD Q20CrMnTi-1/Q20CrMnTi-2 |

| Sucker rod | 20-35CrMoA |

| Free-cutting steel | GT1215S |

| Spring steel | 60Si2MnA 65Mn |

| Ball bearing steel | GCr15 |

Chemical Composition of Hot Work Tool Steel Round Bar Grade 1.2344

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

| Tensile strength (σb/MPa) | Yield strength (σb/MPa) | Elongation (δ5/%) |

| ≥410(42) | ≥245(25) | ≥25 |

Company Introduction of Hot Work Tool Steel Round Bar Grade 1.2344

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Certificates of Hot Work Tool Steel Round Bar Grade 1.2344

Packaging & Delivery of Hot Work Tool Steel Round Bar Grade 1.2344

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

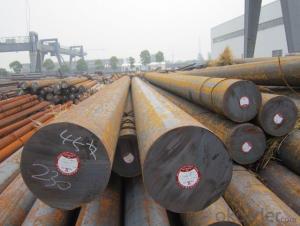

Products show of Hot Work Tool Steel Round Bar Grade 1.2344

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the production of gears?

- Yes, special steel can be used in the production of gears. Special steel is often chosen for gear manufacturing due to its high strength, durability, and resistance to wear and fatigue. It allows for the production of gears that can withstand heavy loads, high speeds, and harsh operating conditions.

- Q: How does special steel perform in magnetic applications?

- Special steel performs well in magnetic applications due to its high magnetic permeability and low electrical conductivity. This allows it to efficiently conduct and concentrate magnetic fields, making it ideal for various magnetic devices and applications such as transformers, motors, generators, and magnetic sensors. Additionally, special steel can exhibit excellent magnetic properties such as high saturation magnetization and low coercivity, making it capable of generating strong magnetic fields and maintaining magnetization even in challenging conditions.

- Q: Can special steel be used in the automotive industry?

- Yes, special steel can be used in the automotive industry. Special steel alloys such as high-strength steel, stainless steel, and tool steel are utilized in various automotive components and structures to enhance durability, strength, and corrosion resistance. These steels are commonly used in areas such as chassis, body panels, engine components, and suspension systems, contributing to improved performance, safety, and fuel efficiency in vehicles.

- Q: Carbon steel and stainless steel and pattern steel and special steel and high carbon steel difference

- Because of the different colors of steel, showing special patterns, steel should be relatively small amount of steel, such as n690 is a special stainless steel, high hardness

- Q: How is special steel used in the medical supply chain?

- Special steel is used in the medical supply chain for a variety of applications. It is utilized in the manufacturing of surgical instruments, implantable devices, and medical equipment due to its high strength, corrosion resistance, and biocompatibility. Special steel ensures the durability and reliability of these critical medical supplies, contributing to the safety and effectiveness of healthcare procedures and treatments.

- Q: Can special steel be used in the aerospace defense industry?

- Yes, special steel can be used in the aerospace defense industry. Special steel alloys such as high-strength steels, stainless steels, and nickel-based alloys are commonly utilized in the production of various components and structures for aerospace defense applications. These materials offer excellent mechanical properties, corrosion resistance, and durability, making them suitable for critical applications in the aerospace defense industry.

- Q: How is special steel used in the railway supply chain?

- Special steel is used in the railway supply chain for various important purposes. It is primarily utilized in the manufacturing of railway tracks, wheels, and axles due to its exceptional strength, durability, and resistance to wear and tear. Special steel is also employed in the production of railway components such as couplings, springs, and fasteners, ensuring the overall safety and efficiency of the railway system.

- Q: How is die steel used in metal stamping processes?

- Die steel is commonly used in metal stamping processes due to its high strength, hardness, and wear resistance properties. It is used to create dies, which are specialized tools that shape and cut metal sheets or strips into desired shapes. Die steel ensures that the dies can withstand the high forces and repetitive actions involved in metal stamping, allowing for precise and efficient production of various metal components and products.

- Q: What is the role of research and development in advancing special steel technology?

- Research and development (R&D) plays a crucial role in advancing special steel technology. Special steel refers to steel alloys that are specifically designed to possess enhanced properties such as high strength, corrosion resistance, heat resistance, or electrical conductivity. R&D activities are essential for pushing the boundaries of special steel technology and developing new and improved alloys. Through continuous research, scientists and engineers are able to explore new compositions, manufacturing processes, and heat treatment techniques to enhance the properties and performance of special steels. One of the primary roles of R&D in advancing special steel technology is the discovery and development of new alloy compositions. R&D teams analyze the properties of different elements and their interactions to design steel alloys with desired characteristics. This involves conducting experiments, testing various compositions, and optimizing the alloy to meet specific application requirements. By fine-tuning the composition, R&D helps in enhancing the strength, hardness, toughness, or other desirable properties of special steels. Furthermore, R&D also focuses on developing innovative manufacturing processes for special steel production. These processes involve advanced techniques such as vacuum melting, rapid solidification, or powder metallurgy to obtain a refined microstructure and improved mechanical properties. R&D teams work on optimizing these processes to enhance the overall quality, efficiency, and cost-effectiveness of special steel production. Another crucial role of R&D is the improvement of heat treatment techniques for special steels. Heat treatment is a critical step in the fabrication of special steels as it helps to achieve desired microstructures and properties. R&D endeavors to optimize the heat treatment parameters, such as temperature, time, and cooling rates, to enhance the mechanical properties and performance of special steels. In addition to alloy composition, manufacturing processes, and heat treatment, R&D also plays a vital role in developing new testing and characterization methods for special steels. This enables the evaluation and validation of the properties and performance of these steels under various conditions. Advanced testing techniques such as electron microscopy, X-ray diffraction, and mechanical testing are employed to assess the microstructural features, phase transformations, and mechanical behavior of special steels. Overall, research and development activities are indispensable for advancing special steel technology. Through continuous research, innovation, and optimization, R&D teams contribute to the development of new and improved alloys, manufacturing processes, heat treatment techniques, and testing methods, ultimately leading to the advancement of special steel technology and its applications in various industries such as automotive, aerospace, energy, and construction.

- Q: What are the requirements for special steel used in marine applications?

- Special steel used in marine applications must meet several specific requirements to ensure its durability and performance in harsh marine environments. These requirements include: 1. Corrosion resistance: Marine environments expose steel to saltwater, which can cause corrosion. Therefore, special steel used in marine applications must have high resistance to corrosion to prevent degradation and maintain its structural integrity over time. 2. Strength and toughness: Steel used in marine applications must have sufficient strength and toughness to withstand the dynamic forces and impacts experienced at sea. It should be able to withstand heavy loads, extreme temperatures, and impact from waves or collisions. 3. Weldability: Special steel for marine applications should have good weldability to facilitate the construction and repair of marine structures. Weldability ensures that the steel can be easily joined without compromising its structural integrity. 4. Fatigue resistance: Marine structures and vessels are subjected to cyclic loading, which can lead to fatigue failure if the steel is not designed to resist it. Special steel used in marine applications should have excellent fatigue resistance to withstand the constant cyclic loading associated with wave motions, currents, and operational conditions. 5. Low-temperature toughness: Marine applications often involve operations in cold climates or icy waters. Special steel used in marine applications should maintain its toughness and ductility even at low temperatures to prevent brittle fracture and ensure safety. 6. Fire resistance: Fire safety is crucial in marine applications. Therefore, special steel used in marine structures should have high fire resistance to prevent structural collapse and minimize the spread of fire. 7. Easy maintenance: Marine structures are subject to constant exposure to harsh environmental conditions. Therefore, special steel used in marine applications should be easy to maintain and repair, ensuring long-term performance and reducing downtime. To meet these requirements, special steel for marine applications is often alloyed with specific elements such as chromium, nickel, and molybdenum to enhance corrosion resistance, strength, and toughness. Additionally, advanced manufacturing processes and quality control measures are employed to ensure the highest standards of quality and performance in marine applications.

Send your message to us

Hot Work Tool Steel Round Bar Grade 1.2344

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords